Small integrated two-dimensional opto-acoustic galvanometer excitation source

An excitation source, small technology, applied in the direction of material analysis, measuring device, instrument, etc. by optical means, can solve the problems of large mechanical vibration, time-consuming, complicated operation, etc., achieve good dynamic response characteristics, improve detection time, improve The effect of scanning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

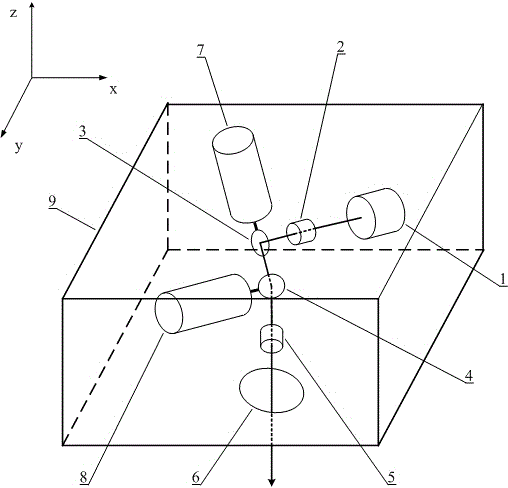

[0017] Embodiment 1 The structure of this embodiment is as follows figure 1 As shown, the names of each component are: 1. Light source, 2. Computer, 3. Acquisition circuit, 4. Preprocessing circuit, 5. Driving circuit, 6. Ultrasonic array sensor, 7. Collimating lens group, 8. X axis Reflective galvanometer, 9. Y-axis reflective galvanometer, 10. Focusing lens group, 11. X-axis motor, 12. Y-axis motor.

[0018] Among them, the light source 1 is a pulsed semiconductor laser diode (PGAS1S24, Hoffo), the working wavelength is 905nm, the peak power is 49W, the pulse width is 150ns, and the single pulse energy is about 7.3uJ; the X-axis and Y-axis motors use precision servo motors, repeat The accuracy can reach 8μrad.

[0019] This example includes laser diode, collimating lens group, X-axis reflective galvanometer, Y-axis reflective galvanometer, focusing lens group, protective mirror, X-axis motor, Y-axis motor, housing; X-axis reflective galvanometer and X-axis motor mechanical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com