Method for measuring moisture content gradient in drying process of woods and measuring sensor used for the method

A technology of wood drying and testing methods, which is applied in the direction of material resistance, etc., can solve the problems of personal safety threats and complex operations of drying kiln operators, and achieve the effects of overall representativeness, accurate test results, and shortening the drying cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

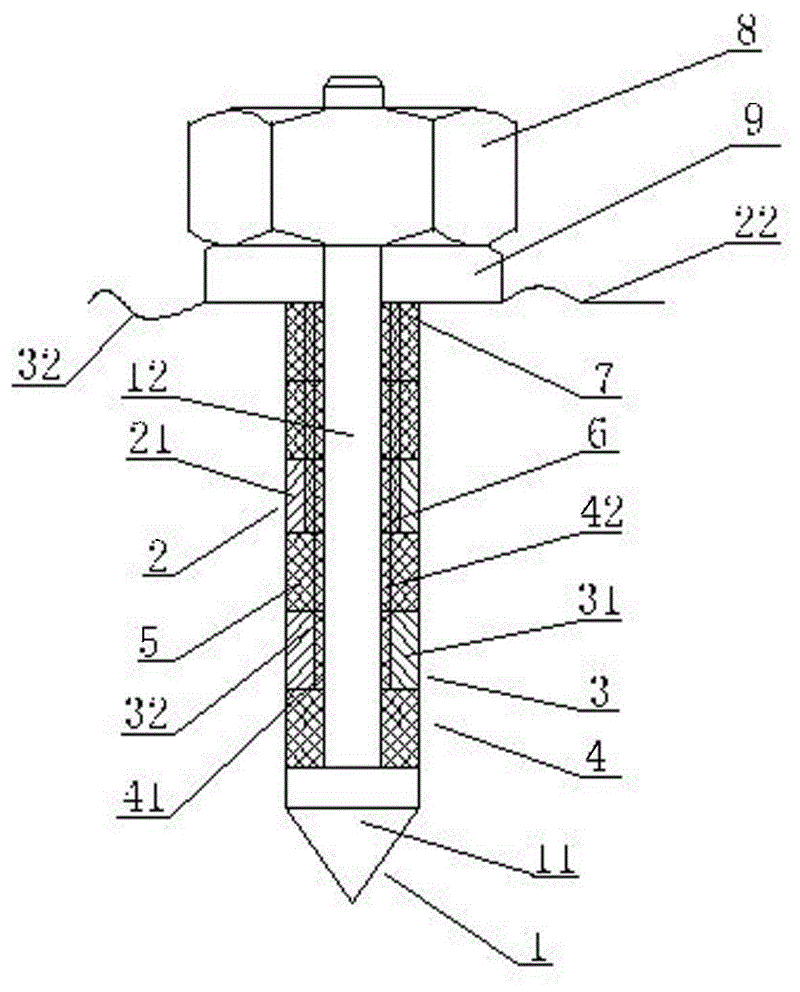

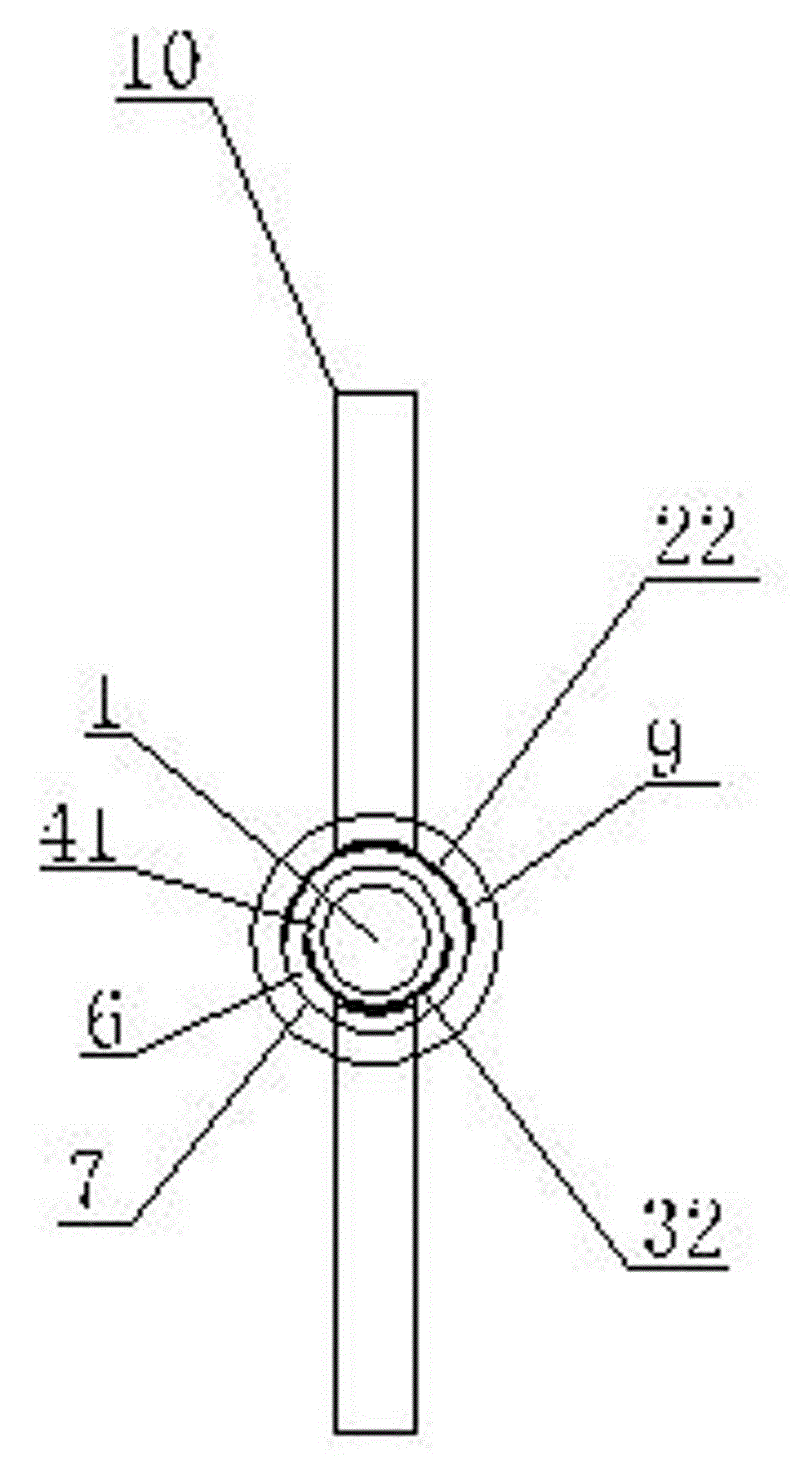

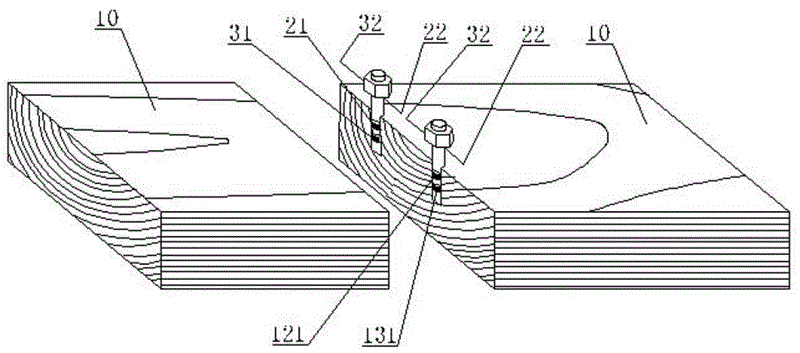

[0018] Such as Figure 1-Figure 3 As shown, the test method for the moisture content gradient in the wood drying process of the present invention comprises the following steps: in the wood drying process, by inserting the test sensor into the wood, it is determined online that at least two different thickness layers of the wood have a certain distance in the width direction Then calculate the moisture content of wood in different thickness layers according to the resistance, and then calculate the moisture content gradient of wood according to the difference of moisture content and the distance between layers of different thickness. During the drying process of the wood, the operator can calculate the moisture content gradient and moisture content deviation on the thickness by online testing the moisture content of the two or more layers of wood resistance conversion on the basis of simple and safe operation, and according to The moisture content gradient is used to judge the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com