Electronic transformer verifying device

An electronic transformer and calibration device technology, applied in the direction of measuring devices, instruments, measuring electrical variables, etc., can solve the problems of lack of digital interface, electronic transformer calibration, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

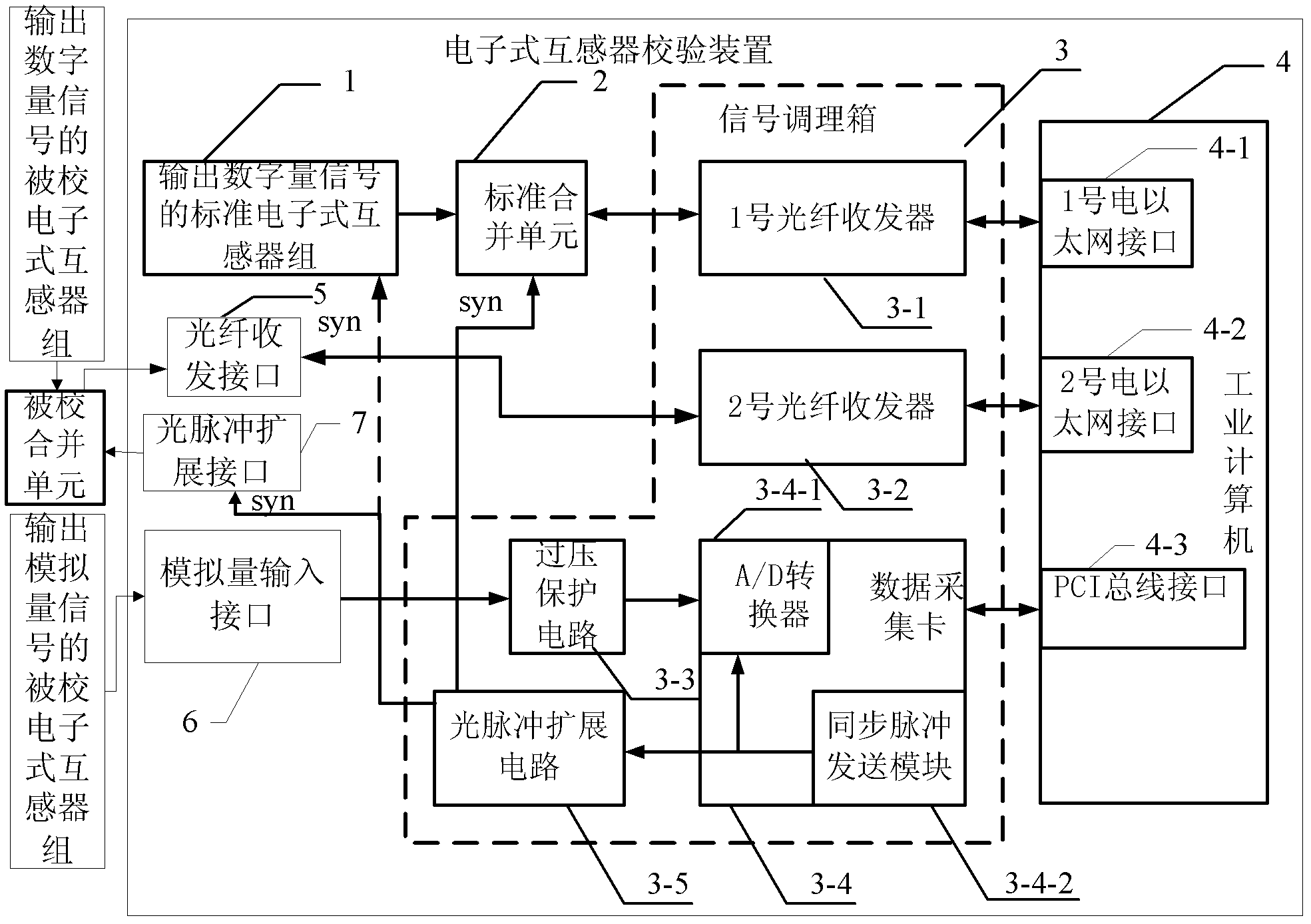

[0017] Specific implementation mode 1. Combination figure 1 Specifically explain this embodiment, an electronic transformer calibration device described in this embodiment, the calibration device includes: a standard electronic transformer group 1 that outputs digital signals, a standard merging unit 2, and a signal conditioning box 3 , industrial computer 4, optical fiber transceiver interface 5, analog input interface 6 and optical pulse expansion interface 7, the signal conditioning box 3 includes: No. 1 optical fiber transceiver 3-1, No. 2 optical fiber transceiver 3-2, overvoltage protection Circuit 3-3, data acquisition card 3-4 and optical pulse expansion circuit 3-5; the data acquisition card 3-4 includes: A / D conversion module 3-4-1 and synchronous pulse sending module 3-4-2 ; The industrial computer 4 is configured with No. 1 electrical Ethernet interface 4-1, No. 2 electrical Ethernet interface 4-2 and PCI bus interface 4-3, and the optical fiber sent by the standar...

specific Embodiment approach 2

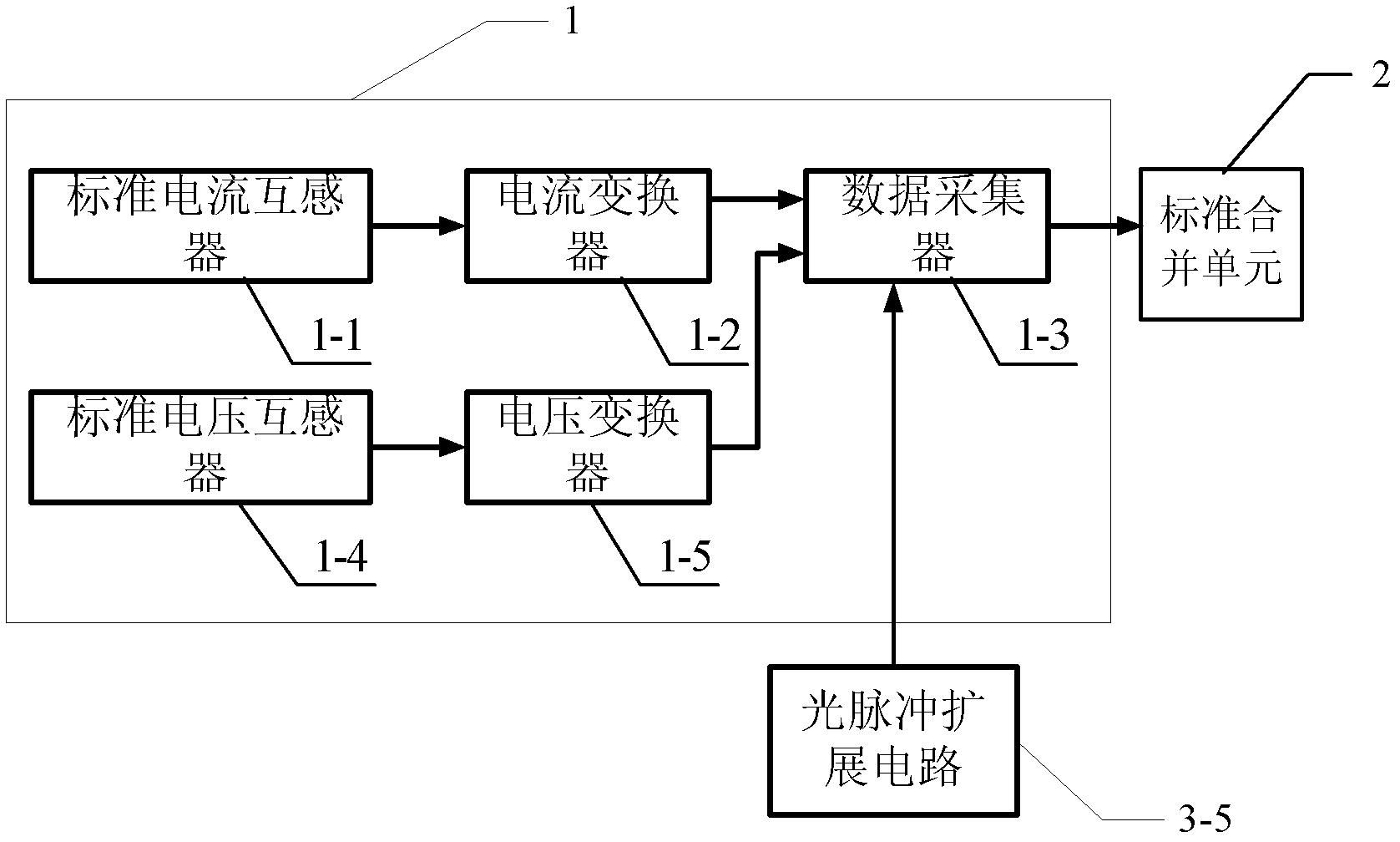

[0022] Specific embodiment two, combine figure 2 Describe this embodiment in detail. The difference between this embodiment and the electronic transformer calibration device described in Embodiment 1 is that the standard electronic transformer group 1 that outputs digital signals includes: standard current transformer 1-1, current transformer 1-2, standard voltage transformer 1-4, voltage transformer 1-5 and data collector 1-3,

[0023] The current signal output terminal of the standard current transformer 1-1 is connected to the current signal input terminal of the current converter 1-2, and the analog current data output terminal of the current converter 1-2 is connected to the analog current data input terminal of the data collector 1-3 ; The voltage signal output terminal of the standard voltage transformer 1-4 is connected to the voltage signal input terminal of the voltage converter 1-5, and the analog voltage data output terminal of the voltage converter 1-5 is connect...

specific Embodiment approach 3

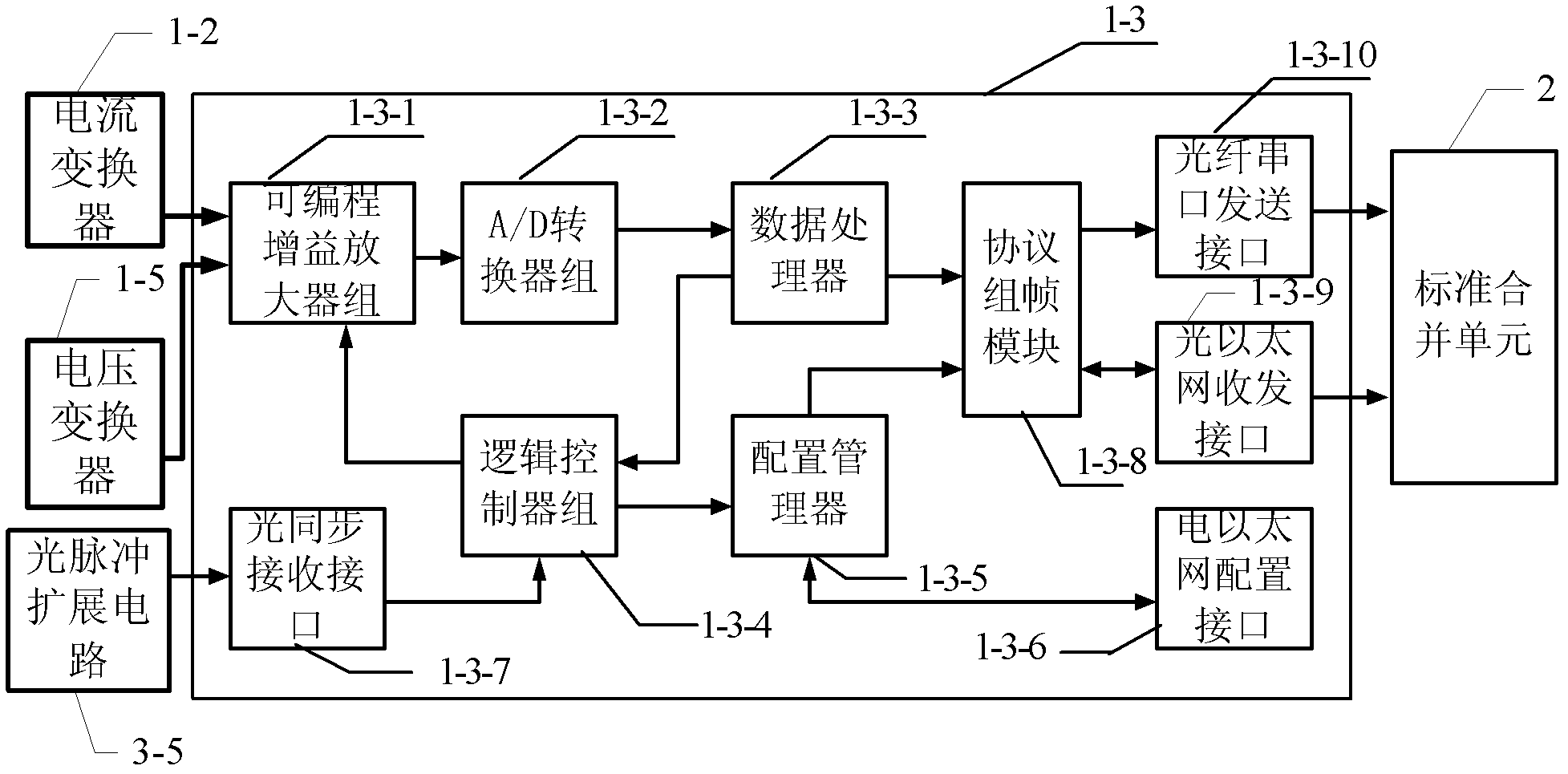

[0024] Specific embodiment three, combine image 3This embodiment is described in detail. The difference between this embodiment and the second embodiment is that the data collector 1-3 includes: a programmable gain amplifier group 1-3-1, an A / D converter group 1-3- 2. Data processor 1-3-3, logic controller group 1-3-4, configuration manager 1-3-5, electrical Ethernet configuration interface 1-3-6, optical synchronization receiving interface 1-3-7 , protocol framing module 1-3-8, optical Ethernet transceiver interface 1-3-9 and optical fiber serial port transmission interface 1-3-10;

[0025] The analog current signal of the current converter 1-2 and the analog voltage signal of the voltage converter 1-5 are simultaneously sent to the programmable gain amplifier group 1-3-1, and the analog current signal received by the programmable gain amplifier group 1-3-1 The signal is amplified according to its initial gain and sent to the A / D converter group 1-3-2, and the A / D converter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com