Rubbing roller and manufacturing method thereof

A manufacturing method and rubbing roller technology, applied in optics, instruments, nonlinear optics, etc., can solve problems such as intrusion, liquid crystal display substrate quality degradation, etc., and achieve the effect of increasing the dangerous speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

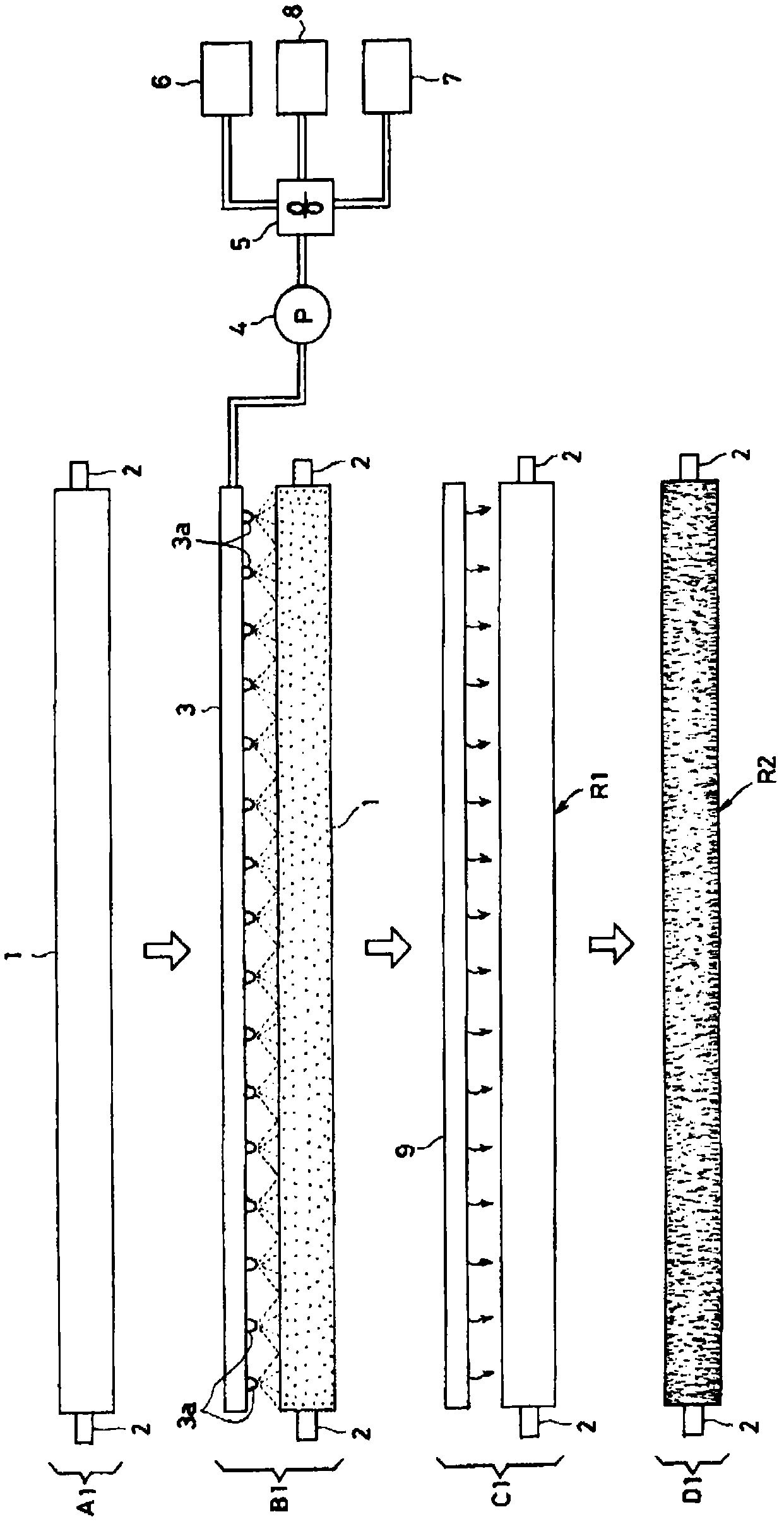

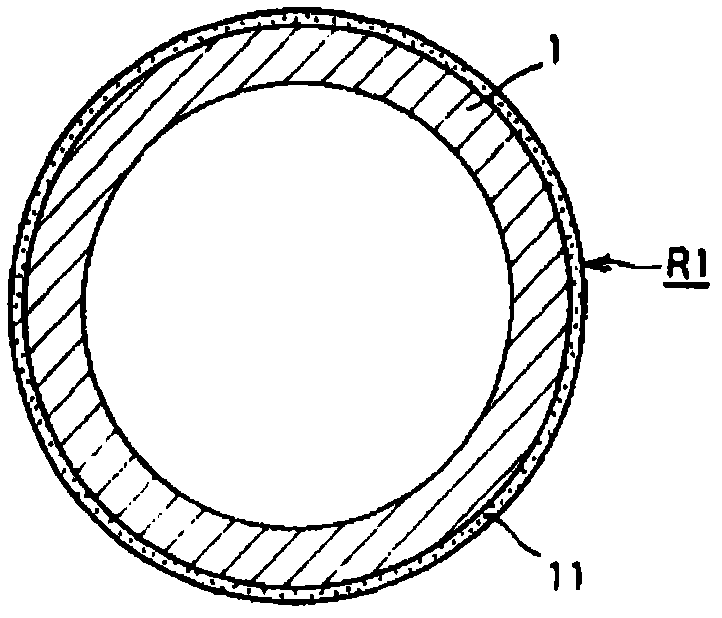

[0047] figure 1 It is a figure which shows the process of the manufacturing method of the friction roller of this invention which concerns on Example 1. As shown in this figure, in process A1, the metal rotating shaft is attached to both ends of CFRP1 which formed the hollow cylindrical shape with a predetermined diameter. Supports flange 2 and prepares for molding. Next, in step B1, above the CFRP 1, the spray device 3 in which a plurality of nozzles 3a are arranged in a row is disposed. The spraying device is connected to a pump 4 and then to a mixer 5 .

[0048]Taking epoxy resin as a thermosetting resin as an example, on the above-mentioned mixer 5, a main agent tank 6 storing the main agent and a curing agent tank 7 storing a curing agent which is mixed with the main agent to start curing are connected. , There is also a conductive material tank 8 for storing the conductive material mixed with the main agent and the curing agent.

[0049] The raw materials mentioned a...

Embodiment 2

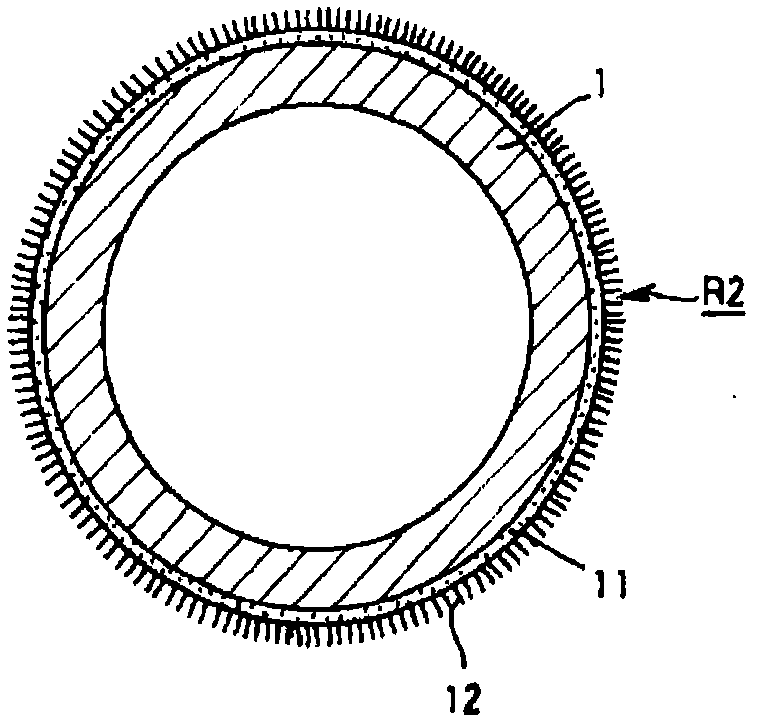

[0054] Figure 4 The process of the manufacturing method of the rubbing roller of this invention of Example 2 is shown, and the thicker conductive epoxy resin layer 11 is formed on the surface of CFRP1, and the member which can improve rigidity is formed. At the same time, the unevenness of the surface of CFRP 1 does not affect the conductive epoxy resin layer 11, and the conductive epoxy resin layer 11 has a smooth surface.

[0055] In the method of embodiment 2, utilize Figure 4 The process shown performs molding processing, and a molding cylinder 13 is used as shown in the figure. The molding cylinder 13 is a hollow cylindrical member made of high corrosion-resistant steel such as stainless steel, its two ends are open, and the inner peripheral surface is coated with, for example, polytetrafluoroethylene, that is, Teflon (registered trademark), to form a hollow cylinder. mold layer.

[0056] At the lower end of the above-mentioned molding cylinder 13, as Figure 5 A se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com