Automatic control method for LED surface mounting machine

A technology of LED placement machine and controller, which is applied in the direction of computer control, program control, general control system, etc., can solve the problems of low work efficiency and inability to meet large-scale production, and achieve the effect of improving placement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

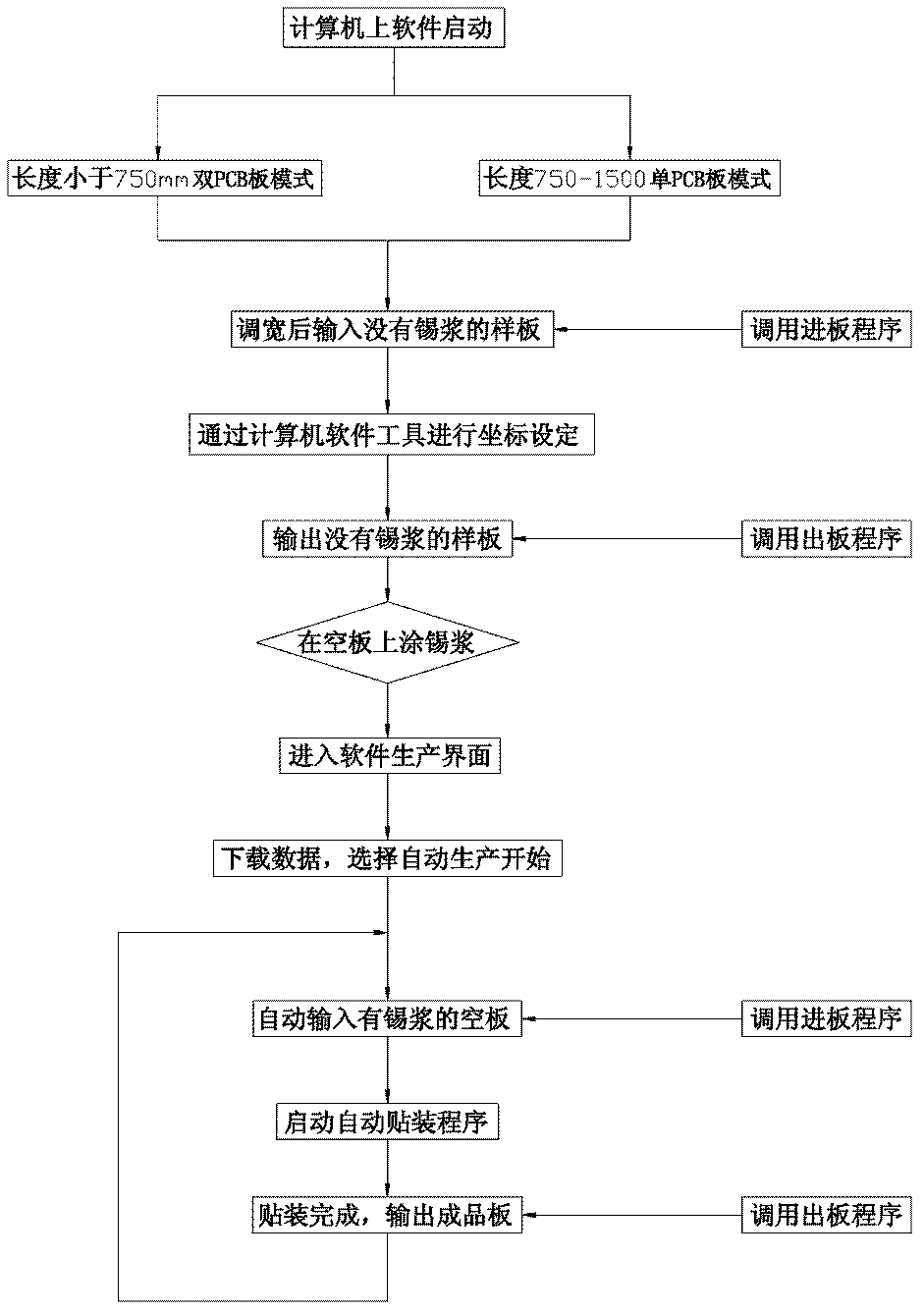

[0060] Such as figure 1 As shown, the automatic control method of the LED placement machine is as follows: (1) Start the computer software; (2) Select the double PCB board mode or single PCB board mode; (3) After the width is adjusted, the board entry program is called to input the template without solder paste ; (4) Coordinate setting by computer software; (5) Call the board output program to output a sample without tin paste; (6) After all the empty boards are coated with tin paste, the LED patch production operation starts; (7) Enter Software production interface; (8) Call the board-in program to input an empty board with tin paste; (9) Start the placement program; (10) After the placement is completed, call the board-out program to output the finished board that has been placed.

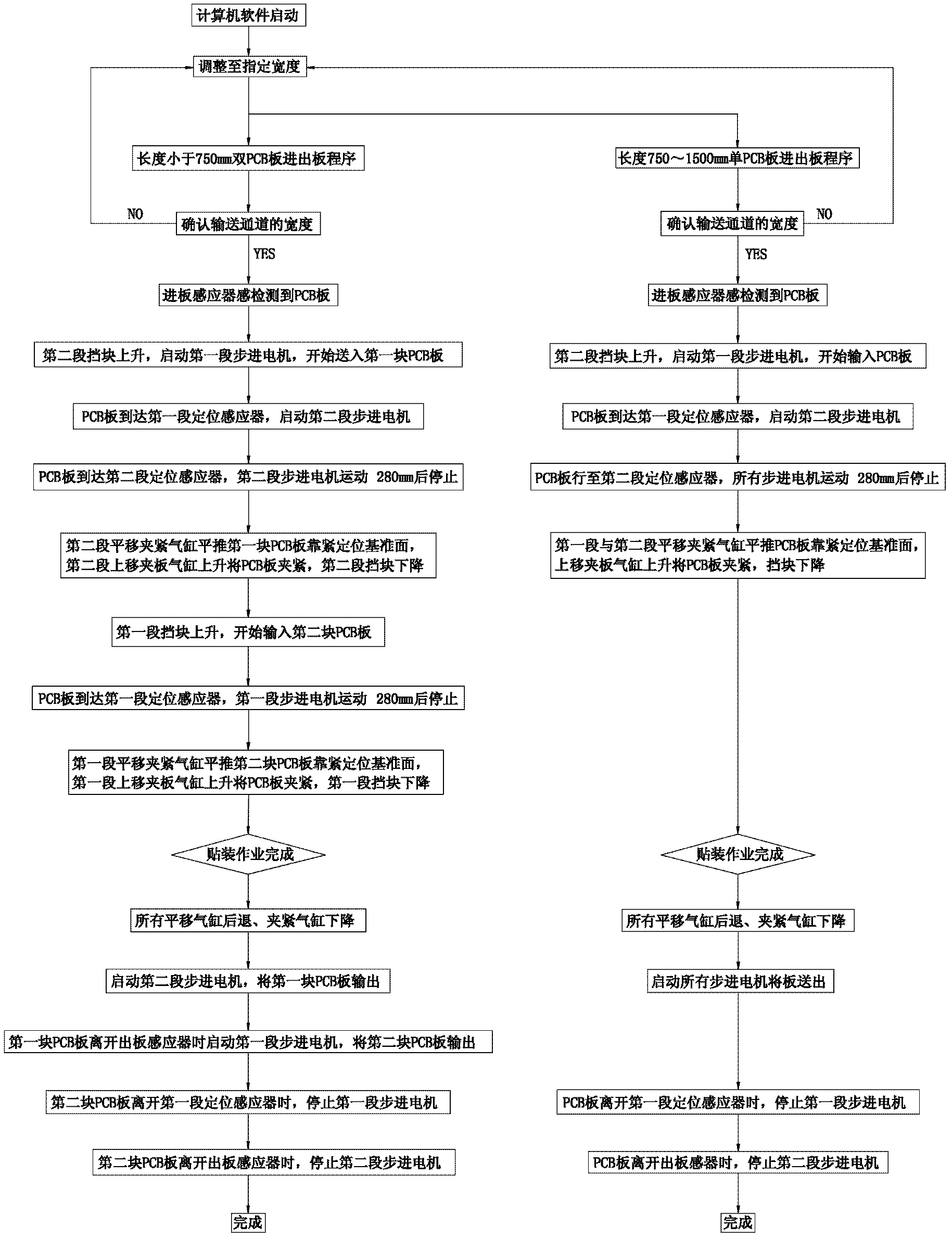

[0061] Such as image 3As shown, the automatic control method of the board feeding in the automatic control method of the LED placement machine includes a double PCB board entry and exit program...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com