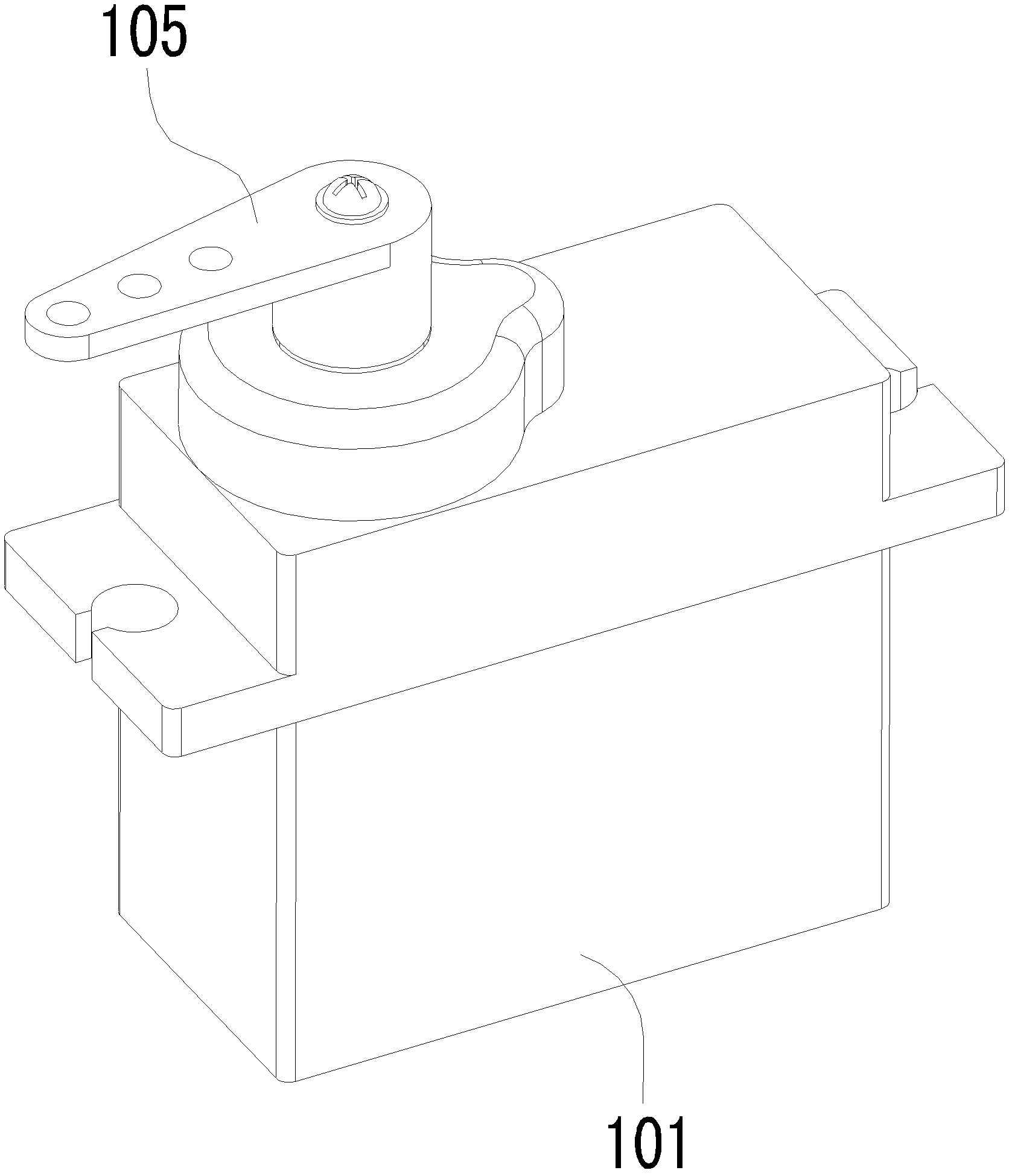

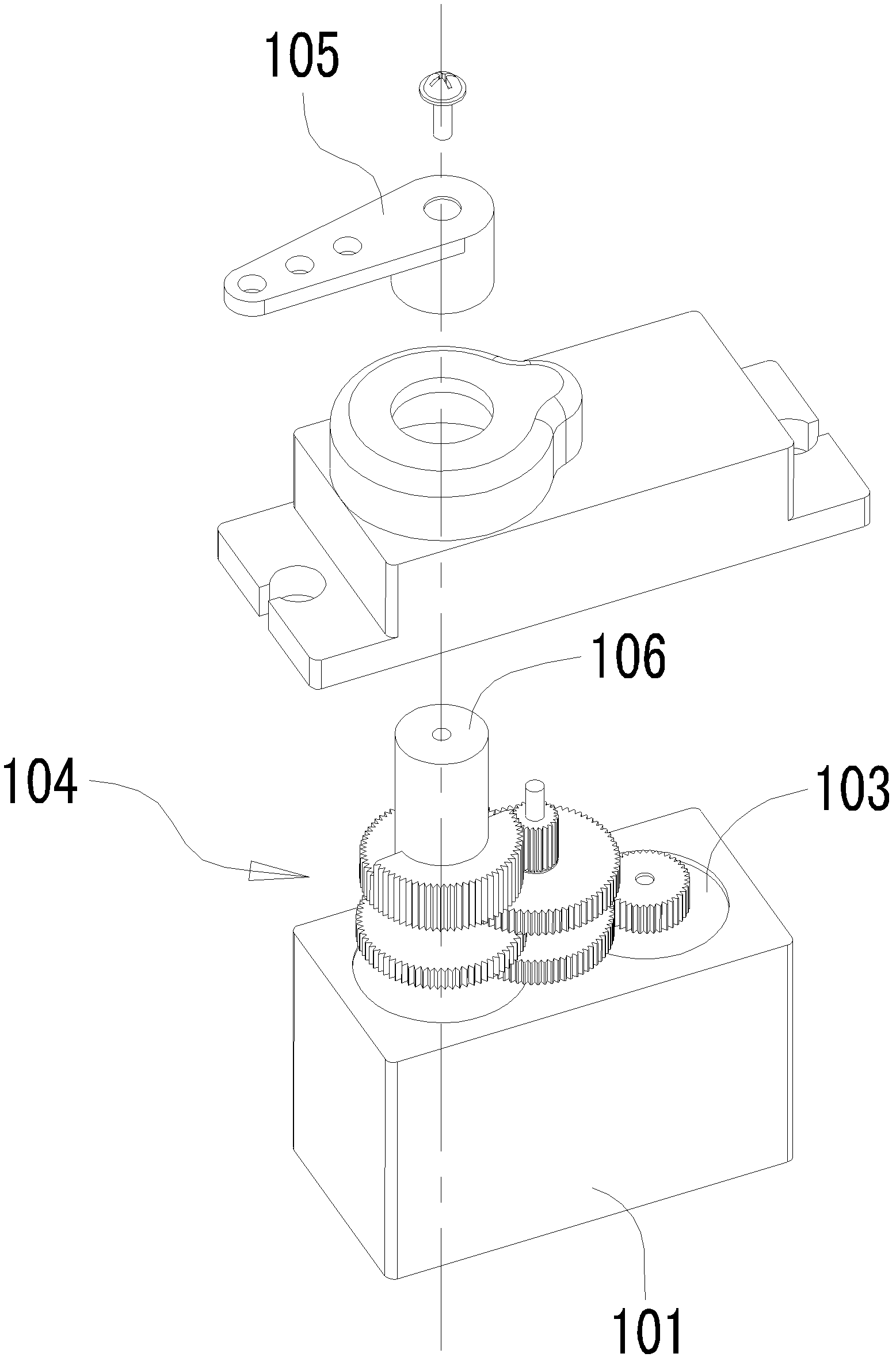

Buffering mechanism on output shaft of power output device and servo motor comprising same

A buffer mechanism and power output technology, applied in the field of servo motors, can solve problems such as gear damage of the reducer and failure of the servo motor to operate normally, and achieve the effects of eliminating inertial force, simple structure, and simple and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

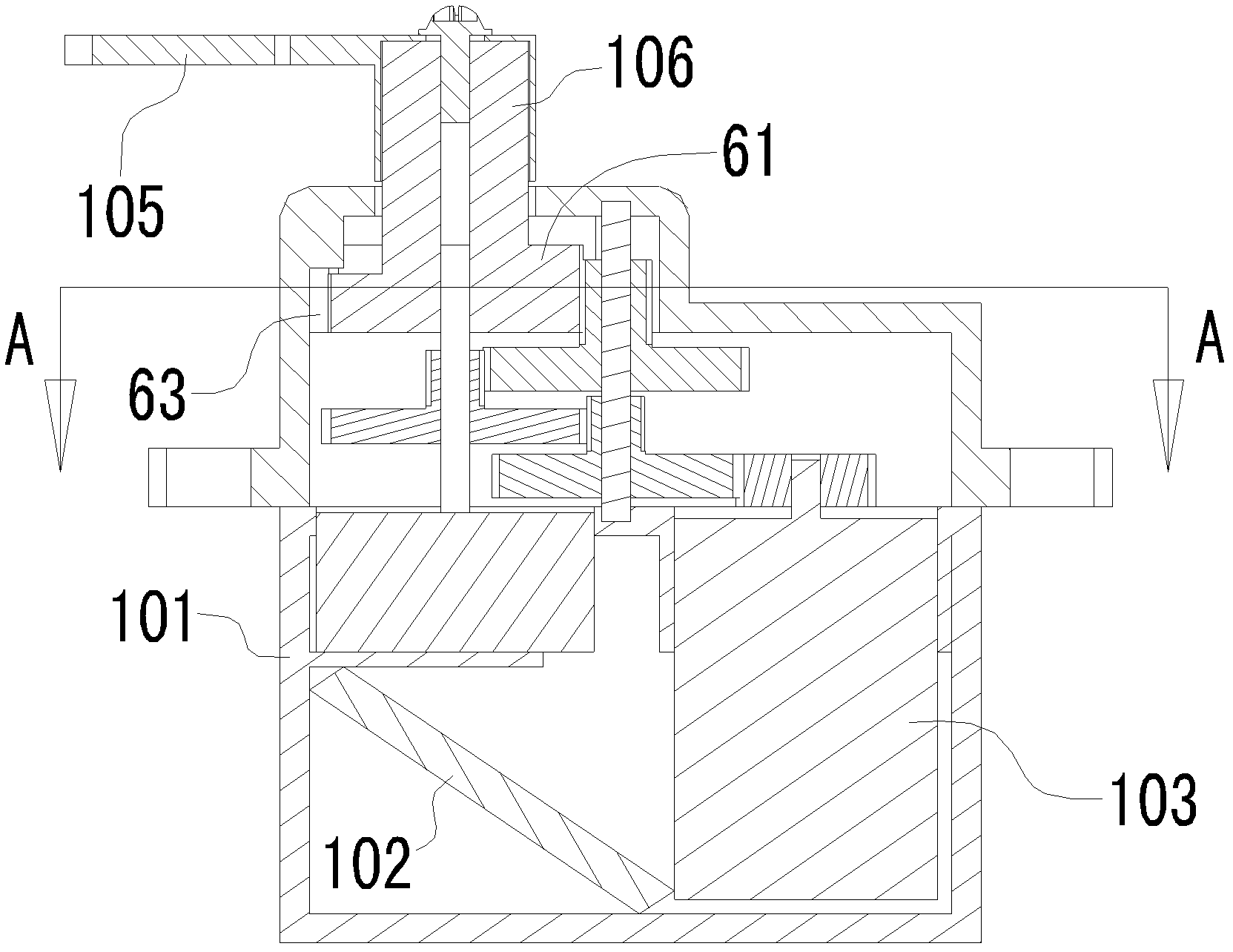

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0040] Such as Figure 5 to Figure 14 As shown, a buffer mechanism on the output shaft of a power output device, the buffer mechanism 1 is connected to a load connector (not shown in the figure), and the output shaft drives the buffer mechanism 1 to drive the load connector to move. The buffer mechanism 1 It includes the first layer of rotating parts 2 and the second layer of rotating parts 3 arranged in layers. The first layer of rotating parts 2 is fixedly installed on the output shaft 11. The second layer of rotating parts 3 is provided with a second pivot hole 31 through which a screw 32 penetrates. Screw the output shaft 11 through the second pivot hole 31 to rotatably install the second layer of rotating member 3 on the output shaft 11 and stack it on the top of the first layer of rotating member 2. The screw 32 and the second p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com