Spiral and axial circulating cooling water channel structure for motor

A motor cooling, helical axial technology, applied in the electrical field, can solve the problems of inability to improve the heat transfer coefficient and heat transfer rate, difficult sealing, uneven heat transfer, etc., to achieve increased heat transfer coefficient, reliability and manufacturability. The effect of improving and reducing the temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

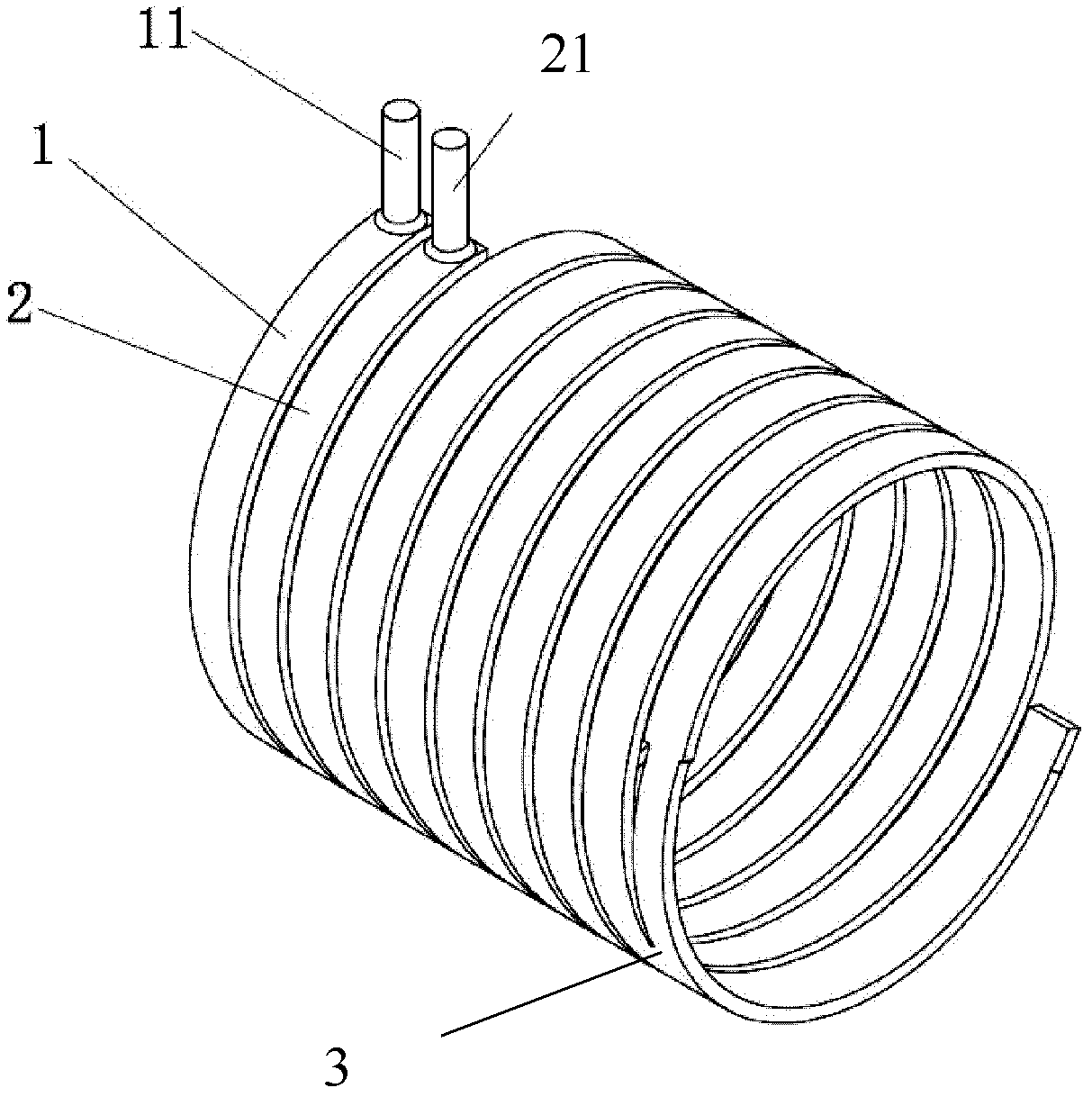

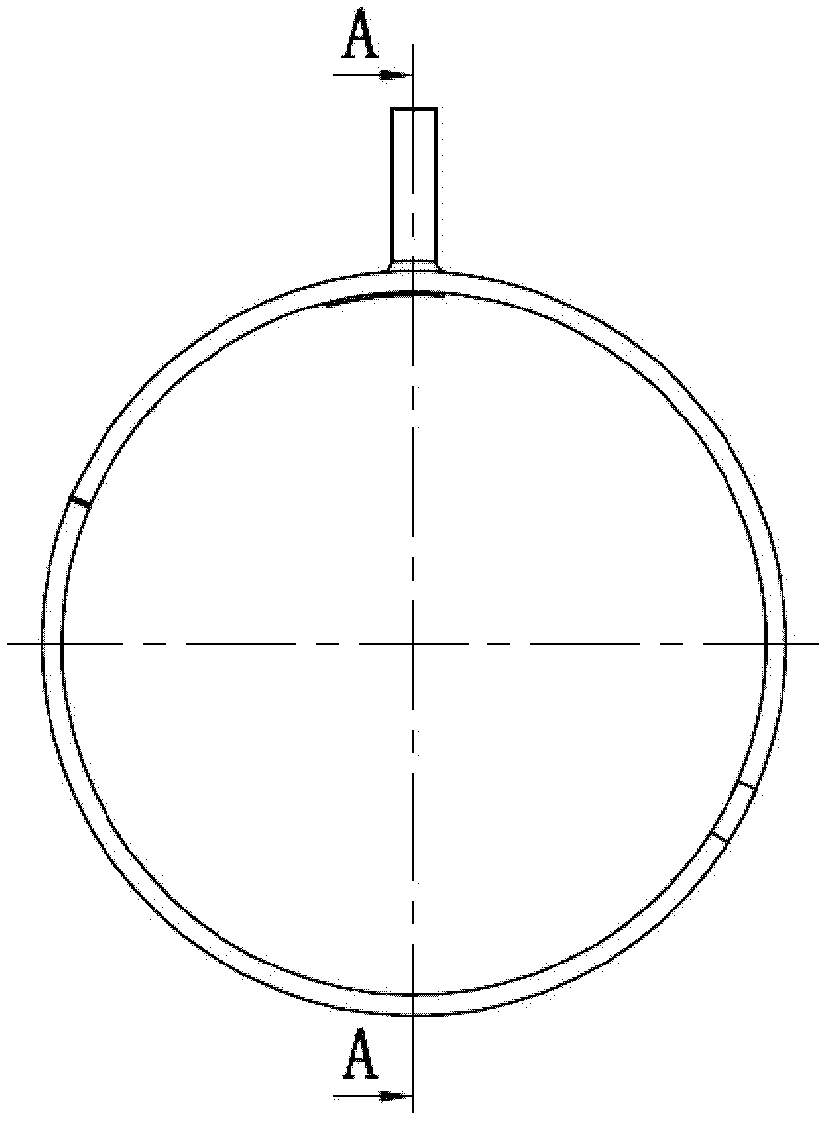

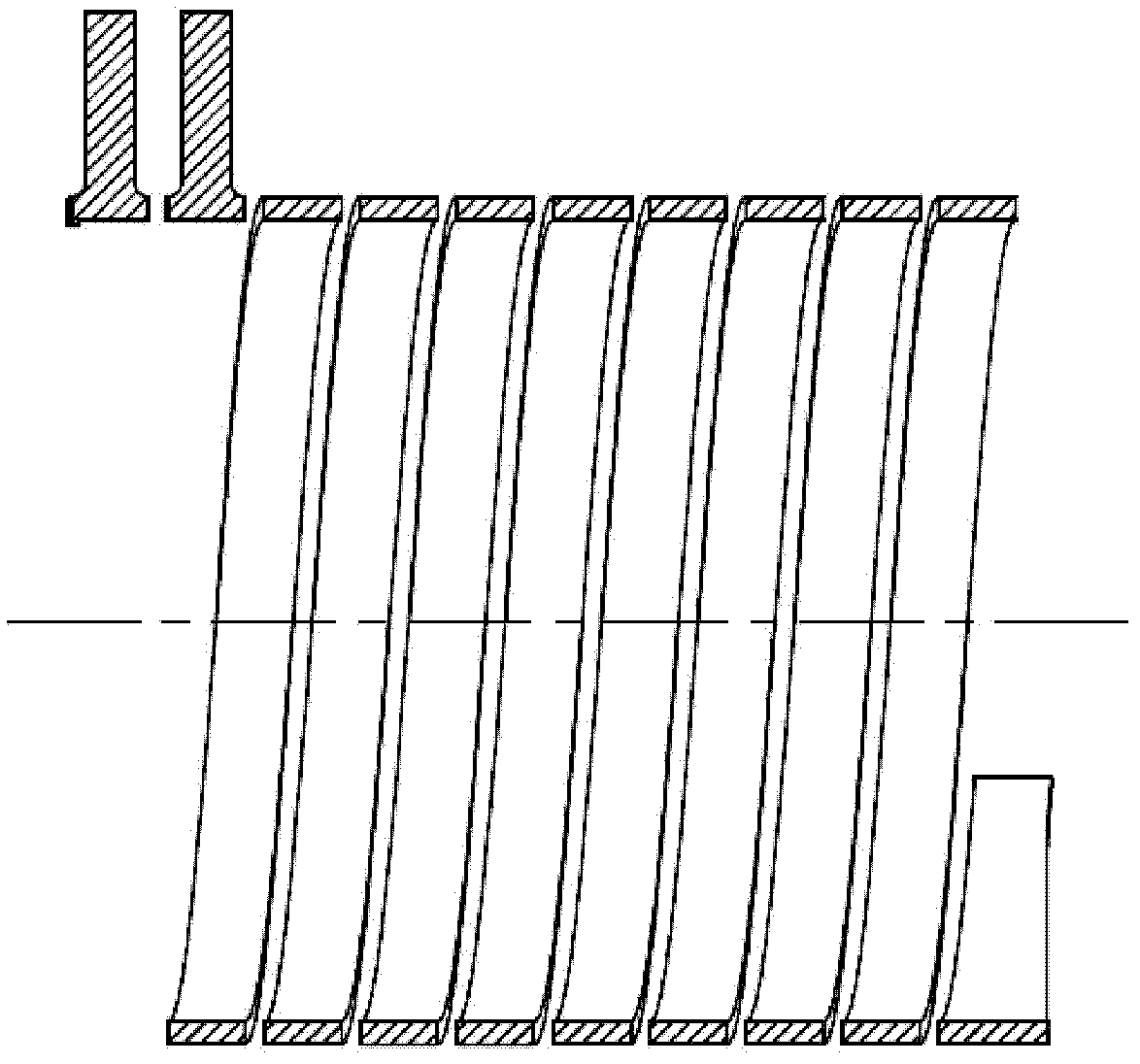

[0015] Such as figure 1 , figure 2 and image 3 As shown, a spiral axial circulating motor cooling channel structure of the present invention includes a stator core (not shown in the figure) of the motor, and a cooling channel is arranged in the stator core, wherein the cooling channel Including a first spiral channel 1 and a second spiral channel 2, the first spiral channel 1 and the second spiral channel 2 are juxtaposed, the inlet end of the first spiral channel 1 and the second spiral channel 2 The outlet ends are adjacent, and the outlet end of the first helical channel 1 is adjacent to and communicated with the inlet end of the second helical channel 2 .

[0016] figure 1 Part 3 in represents the connection between the outlet end of the first helical channel 1 and the inlet end of the second helical channel 2 .

[0017] Further, the first helical channel 1 and the second helical channel 2 are arranged in parallel along the axial direction of the stator core.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com