Filtering process and filtering system for use in preparation of injection liquid medicament

A filtration system and injection technology, applied in the direction of filtration separation, filtration circuit, separation method, etc., can solve the problems that steam cannot pass through effectively, the internal damage of the filter element, the pollution of the clean area, etc., so as to eliminate the possibility of adsorbing the main components and reduce the cost of activated carbon Effect of using and guaranteeing the quality of liquid medicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

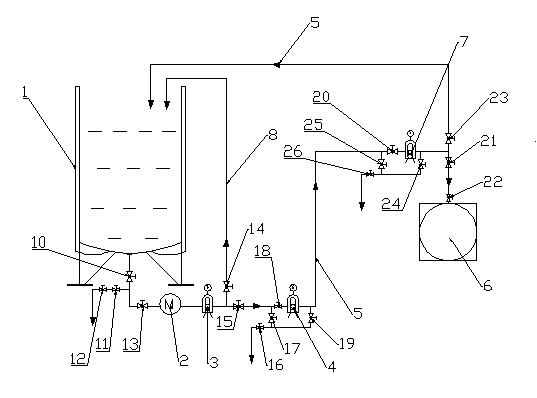

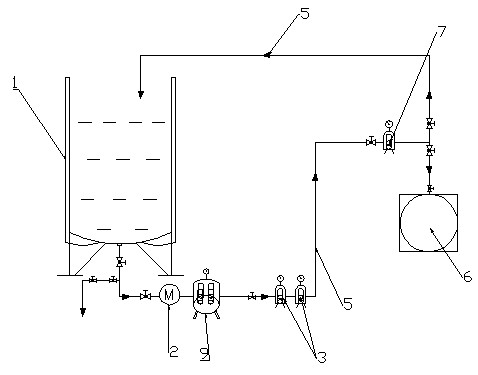

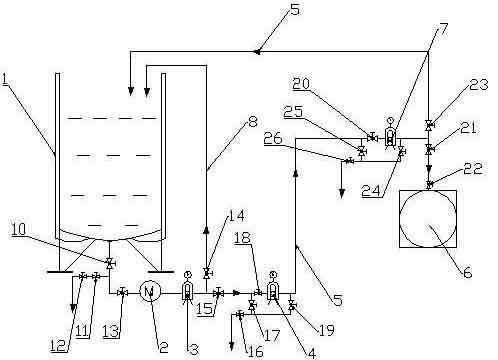

[0025] In the traditional process, two sets of polyethersulfone filter elements are added to filter in series, and a small circulation system is added, and the filter parallel system protects the filter elements.

[0026] The configuration container 1 described in the filtration system is connected to the sewage outlet through valves 11 and 12 through the valve 10, and connected to the liquid medicine pump 2 through the valve 13; after the liquid medicine pump 2 is connected to the polypropylene filter element 3, the valve 14 It is connected with the small circulation pipeline 8, the outlet of the small circulation pipeline 8 is connected with the container mouth of the configuration container 1, and the other way after the liquid medicine pump 2 is connected with the polypropylene filter element 3 passes through the valve 15 and two sets of polyethersulfone filter elements 4, 7 connection, one path of the second group of polyethersulfone filter elements 7 is connected with the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com