Light-emitting diode (LED) anti-explosion lamp

A technology of explosion-proof lamps and lenses, which is applied to lighting devices, cooling/heating devices of lighting devices, light sources, etc., can solve the problems of complex structure of heat dissipation system, small cross-sectional area of heat transfer base, and insufficient heat transfer efficiency, so as to improve heat transfer Thermal efficiency, simple and compact overall structure, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

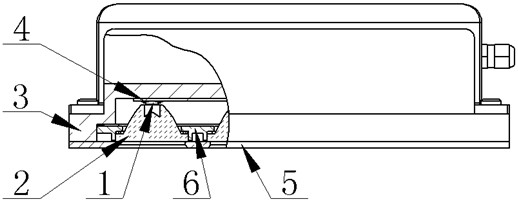

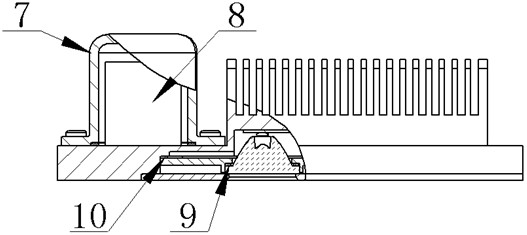

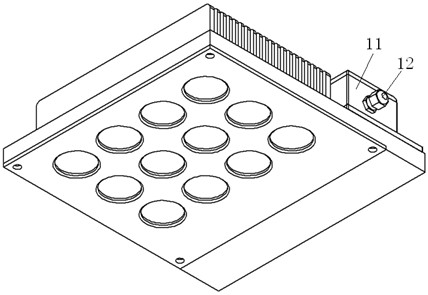

[0024] as attached Figure 1 to Figure 3 As shown, the LED explosion-proof lamp of the present invention is composed of LED1, lens 2, radiator 3, aluminum-based circuit board 4, cover plate 5, support plate 6, drive circuit 8 and its protective shell 7 and other components.

[0025] The LED light source is sensitive to temperature, and reasonable heat dissipation measures should be taken to keep the junction temperature of the LED within the rated range during normal operation. In an explosive environment, the LED1 and its driving circuit 8 are installed in a sealed protective casing 7 , and the heat generated by the LED1 needs to be dissipated to the external environment through the protective casing 7 . The present invention adopts the heat sink 3 in the form of a heat sink, utilizes the characteristics of the small size of the LED, and uses the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com