Electronic phase change detection circuit of position sensor-free brushless direct current motor

A brushed DC motor, detection circuit technology, applied in the direction of electronic commutation motor control, electronic commutator, electrical components, etc., can solve the problems of poor reliability, short life, reduce system reliability, etc., to ensure reliability, strengthen The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

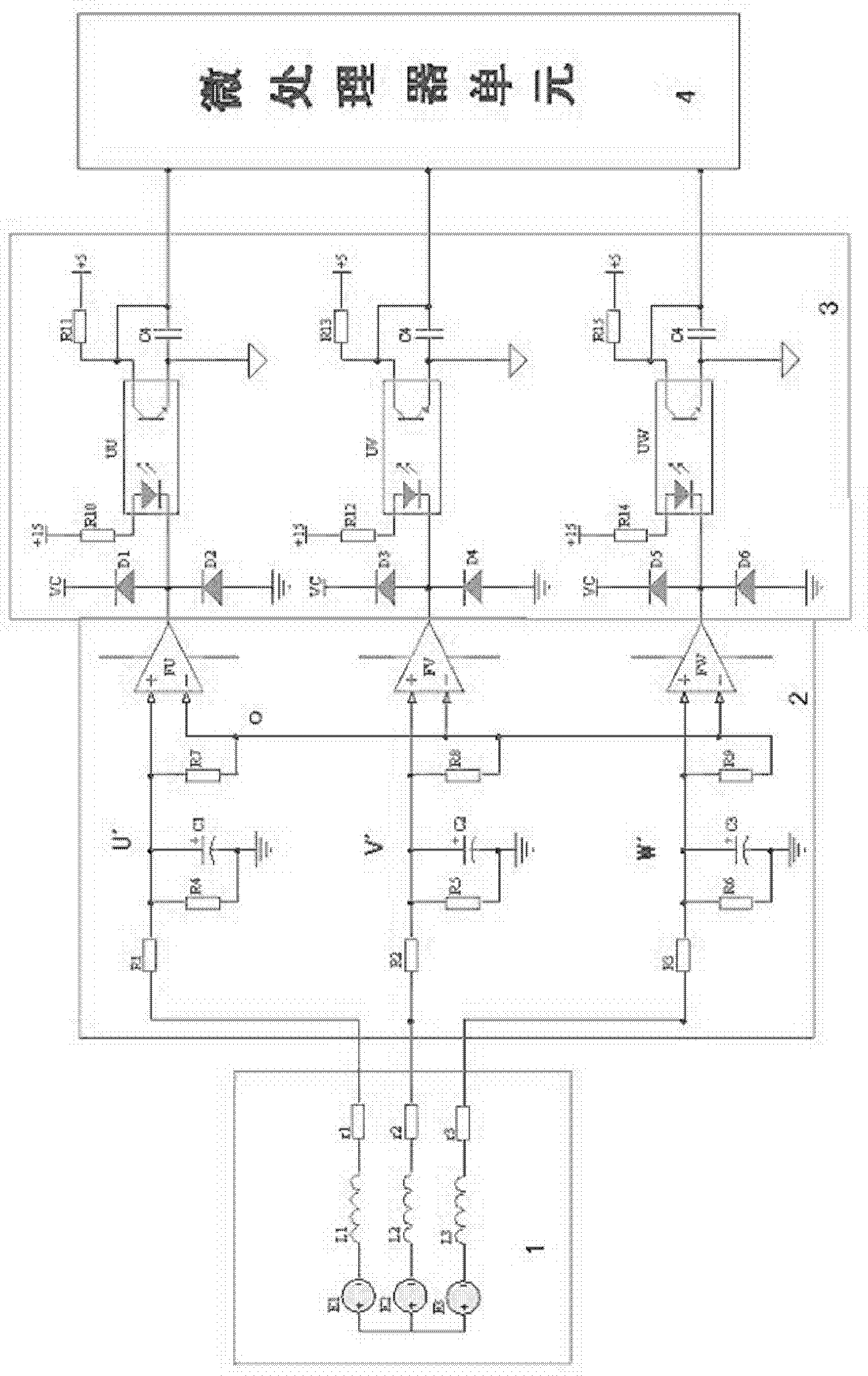

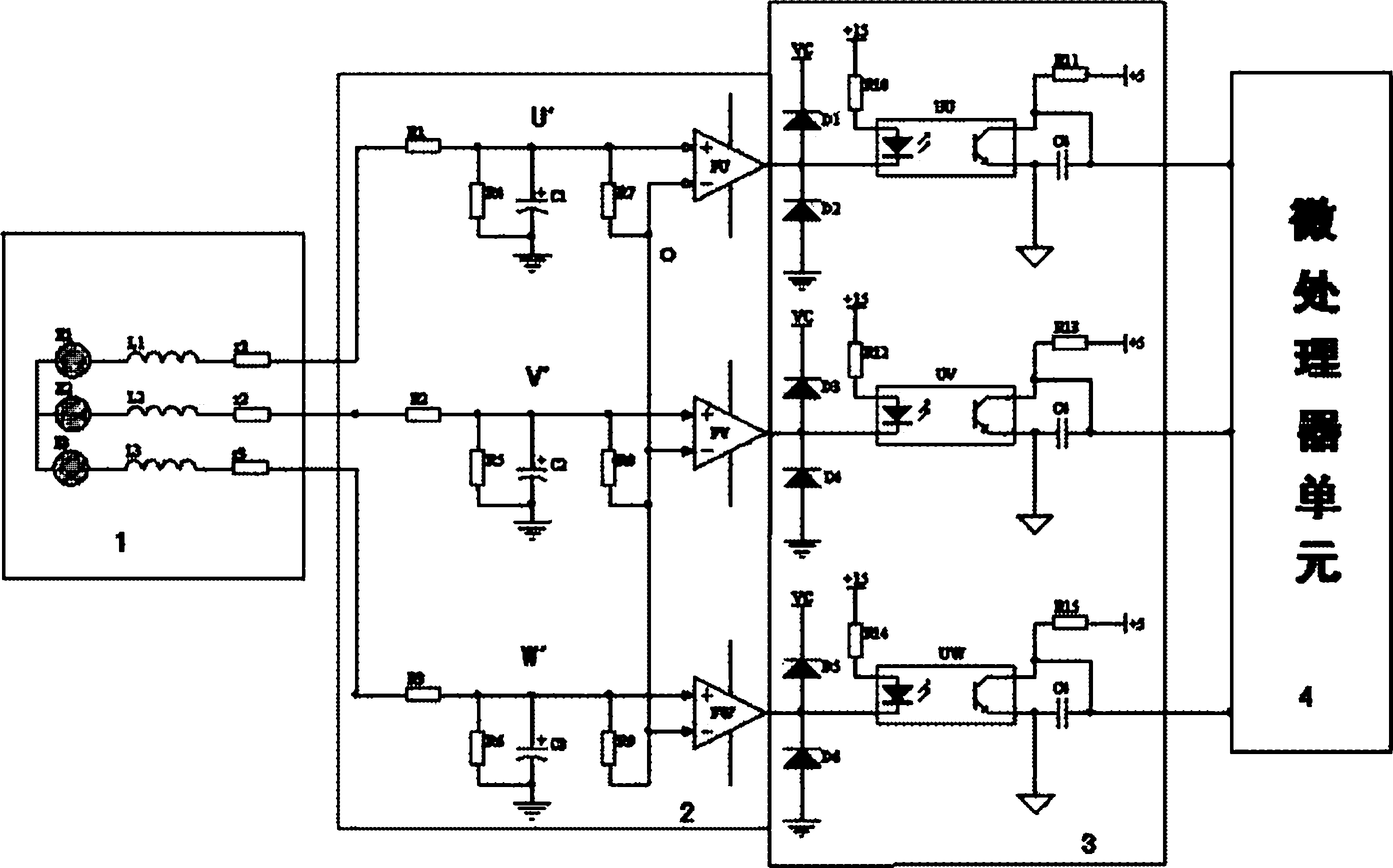

[0019] A brushless DC motor electronic commutation detection circuit without a position sensor, which includes a brushless DC motor equivalent circuit, a counter electromotive force zero-crossing detection circuit, a photoelectric isolation circuit and a microprocessor unit arranged in sequence, and the counter electromotive force zero-crossing The interface of the detection circuit is respectively connected to the three-phase output lines of the equivalent circuit of the brushless DC motor, and the three-phase output lines of the counter electromotive force zero-crossing detection circuit are respectively connected to three groups of independent photoelectric isolation circuits, and the three groups of photoelectric isolation circuits are respectively connected to each other. The output terminals of the circuit are all connected to the microprocessor unit, and the three sets of independent photoelectric isolation circuits are U-phase photoelectric isolation circuit, V-phase pho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com