Superabsorbent antimicrobial nonwoven fabric and antimicrobial dressing, and preparation methods and uses thereof

A non-woven, super-absorbent technology, applied in the direction of absorbent pads, medical science, bandages, etc., to achieve the effects of overcoming slow speed, good antibacterial effect, and overcoming poor strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

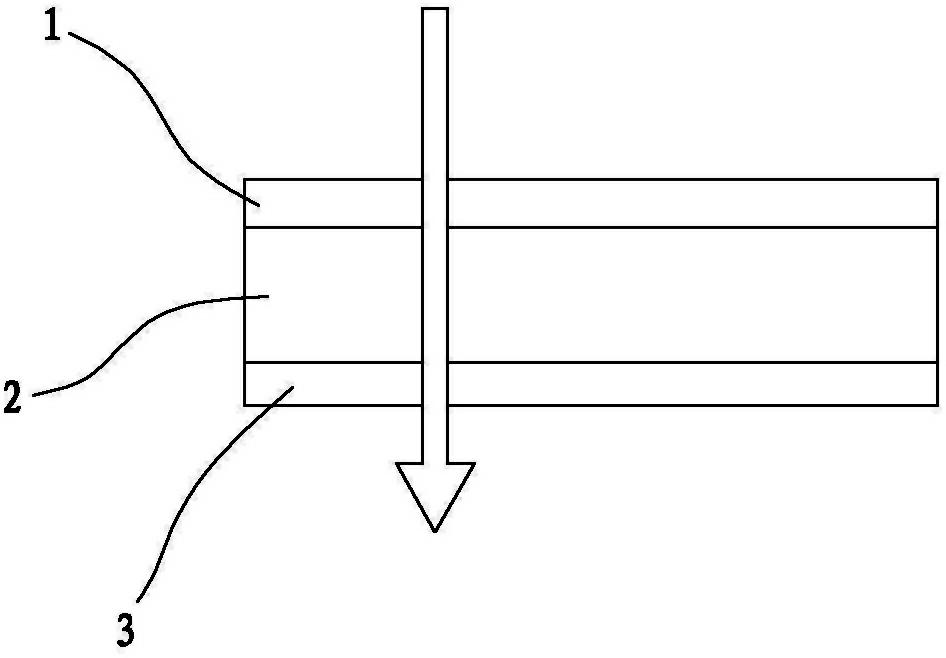

[0043] Embodiment 1: Preparation of superabsorbent antibacterial nonwoven fabric:

[0044] 1) Add fiber according to the following weight ratio:

[0045] Super Absorbent Fiber 35% (from Technical absorbents)

[0046] Cotton Fiber 15% (from Taebong Fiber)

[0047] 25% polyester fiber (purchased from Yizheng Chemical Fiber)

[0048] X-Static Silver Fiber 15% (purchased from Noble Fiber Technologies, USA)

[0049] Polypropylene fiber 10% (purchased from Nantong Chaoliang Fiber Co., Ltd.)

[0050] 2) Combing into a net: follow the general method;

[0051] 3) Reinforcement with hot pressing roller: Set the temperature of the pressing roller to 160°C, heat it to a temperature slightly higher than the melting point of polypropylene fiber at 150°C, and press the carded non-woven fabric under a certain pressure.

Embodiment 2

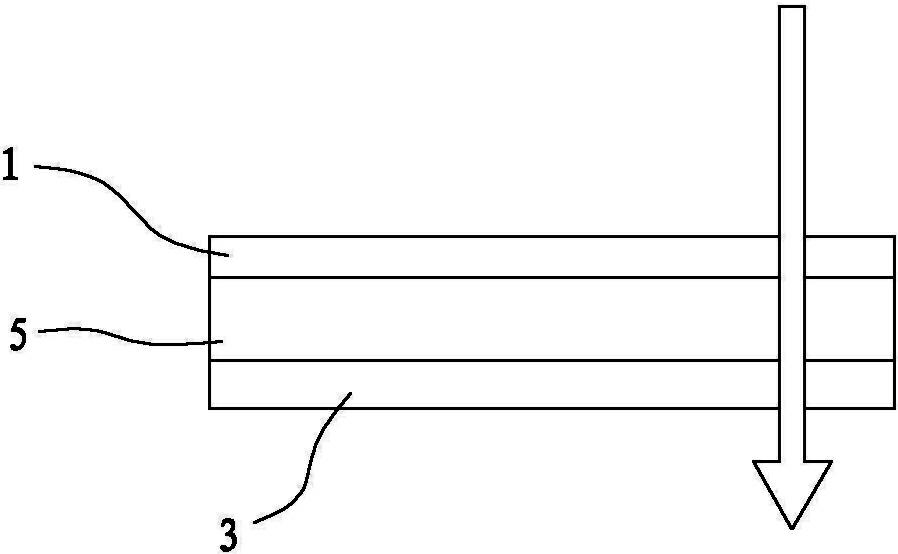

[0052] Embodiment 2: Preparation of superabsorbent antibacterial non-woven fabric:

[0053] 1) Add fiber according to the following weight ratio:

[0054] Super Absorbent Fiber 30% (from Technical absorbents)

[0055] Cotton Fiber 20% (purchased from Taebong Fiber)

[0056] 10% polyester fiber (purchased from Yizheng Chemical Fiber)

[0057]X-Static Silver Fiber 20% (purchased from Noble Fiber Technologies, USA)

[0058] 20% polypropylene fiber (purchased from Nantong Chaoliang Fiber Co., Ltd.)

[0059] 2) Combing into a net: follow the general method;

[0060] 3) Reinforcement with hot pressing roller: Set the temperature of the pressing roller to 160°C, heat it to a temperature slightly higher than the melting point of polypropylene fiber at 150°C, and press the carded non-woven fabric under a certain pressure.

Embodiment 3

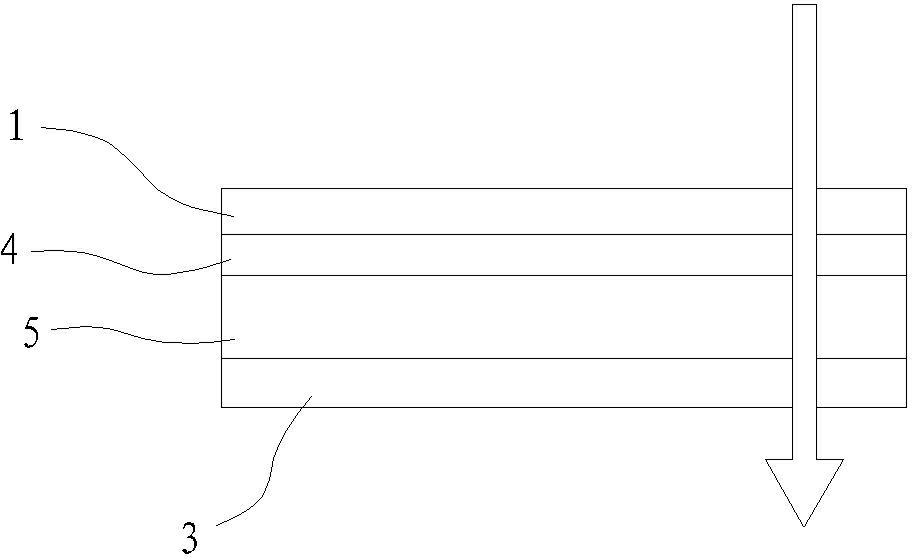

[0061] Embodiment 3: Preparation of superabsorbent antibacterial nonwoven fabric:

[0062] 1) Add fiber according to the following weight ratio:

[0063] Super Absorbent Fiber 50% (from Technical absorbents)

[0064] Cotton Fiber 10% (purchased from Taebong Fiber)

[0065] 20% polyester fiber (purchased from Yizheng Chemical Fiber)

[0066] X-Static Silver Fiber 10% (purchased from Noble Fiber Technologies, USA)

[0067] Polypropylene fiber 10% (purchased from Nantong Chaoliang Fiber Co., Ltd.)

[0068] 2) Combing into a net: follow the general method;

[0069] 3) Reinforcement with hot pressing roller: Set the temperature of the pressing roller to 160°C, heat it to a temperature slightly higher than the melting point of polypropylene fiber at 150°C, and press the carded non-woven fabric under a certain pressure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com