Method and device for preparing tube blank by means of differential temperature pushing from equal circular cross section to variable square cross section

A cross-section, square technology, applied in the direction of manufacturing tools, metal processing equipment, forming tools, etc., can solve the problems of uneven structure and performance of the blank workpiece, actual production obstacles, easy cracks, etc., to achieve good deformation, increase plasticity, increase The effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

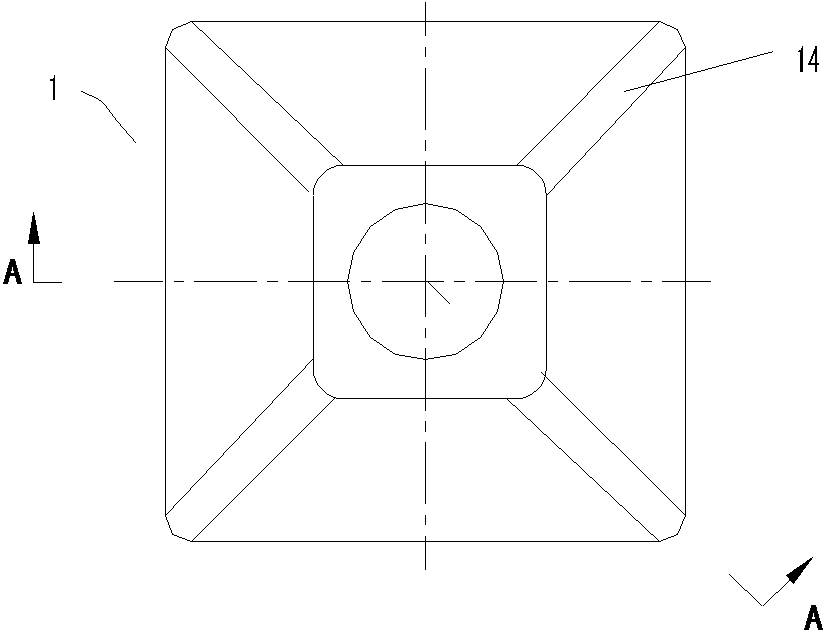

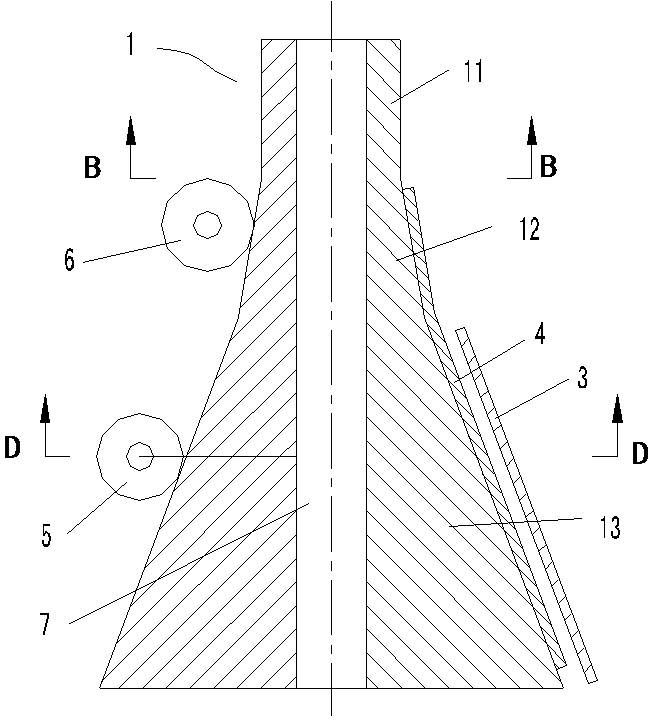

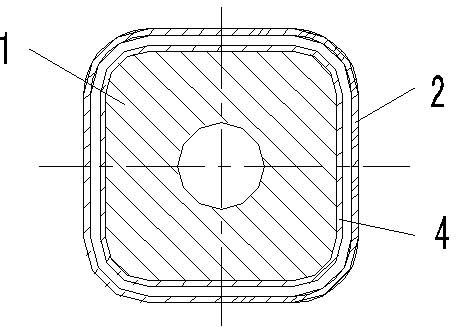

[0040] In this embodiment, the method for preparing a tube billet by differential temperature pushing from a circular section to a variable square section includes the following steps:

[0041] 1) Pushing of the cylindrical section 11: After putting the hollow cylindrical shell 4 on the cylindrical section 11 of the pushing mold 1, turn on the heating jacket 7, heat the shell 4 to 350°C, and keep it warm for 6s. Turn off the heating jacket 7. Heating the billet 4 is used to increase the plasticity of the billet 4 to prepare for subsequent deformation.

[0042] 2) Pushing of the transition section 12: load, push the transition section 12 from the shell 4 to the pushing mold 1 at a speed of 40mm / s, and at the same time turn on the annular heating device 2 to keep the temperature of the shell 4 at 350°C to complete the transition After the stage of pushing deformation, stay for 6s. Such as Figure 6 As shown, the pressing machine 8 is used to apply a pushing force to the shell...

no. 2 example

[0050] In this embodiment, the method for preparing a tube billet by differential temperature pushing from a circular section to a variable square section includes the following steps:

[0051] 1) Pushing of the cylindrical section 11: After putting the hollow cylindrical tube blank 4 on the cylindrical section 11 of the pushing mold 1, turn on the heating jacket 7, heat the tube blank 4 to 340°C, and keep it warm for 8s. Turn off the heating jacket 7. Heating the billet 4 is used to increase the plasticity of the billet 4 to prepare for subsequent deformation.

[0052] 2) Pushing of the transition section 12: load, push the transition section 12 from the shell 4 to the push mold 1 at a speed of 45mm / s, and at the same time turn on the annular heating device 2 to keep the temperature of the shell 4 at 370°C to complete the transition After the stage of pushing deformation, stay for 7s. Such as Figure 6 As shown, the pressing machine 8 is used to apply a pushing force to th...

no. 3 example

[0060] In this embodiment, the method for preparing a tube billet by differential temperature pushing from a circular section to a variable square section includes the following steps:

[0061] 1) Pushing of the cylindrical section 11: After the hollow cylindrical shell 4 is set on the cylindrical section 11 of the pushing mold 1, the heating jacket 7 is turned on, and the shell 4 is heated to 360°C and kept warm for 7s. Turn off the heating jacket 7. Heating the billet 4 is used to increase the plasticity of the billet 4 to prepare for subsequent deformation.

[0062] 2) Pushing of the transition section 12: load, push the transition section 12 from the shell 4 to the push mold 1 at a speed of 43mm / s, and at the same time turn on the annular heating device 2 to keep the temperature of the shell 4 at 400°C to complete the transition After the stage of pushing deformation, stay for 8s. Such as Figure 6 As shown, the pressing machine 8 is used to apply a pushing force to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com