Hot air circulating system for air knife of two-way stretching membrane for extruding and casting

A technology of two-way stretching and circulation system, which can be applied to flat products, household utensils, and other household utensils, and can solve problems such as lack of technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

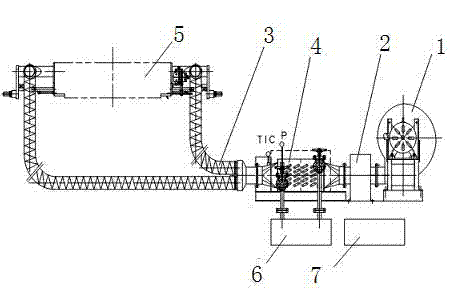

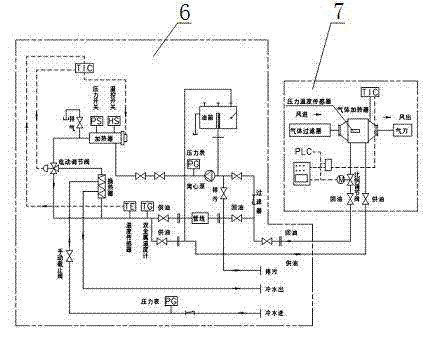

[0012] Such as figure 1 and figure 2 As shown in the figure, the extruded salivating biaxially stretched diaphragm air knife hot air circulation system includes frequency conversion controlled high-pressure centrifugal fan 1, air filter 2, conveying air pipe 3, gas heater 4, air knife 5, hot oil station 6 and The temperature and pressure control unit 7, the air filter 2 are respectively connected with the frequency conversion controlled high-pressure centrifugal fan 1 and the air heater 4 through connecting pipes, one end of the conveying air pipe 3 is connected with the air knife 5, and the other end is connected with the gas heater 4, The oil inlet and outlet pipes of the gas heater 4 are connected with the thermal oil station 6 and the temperature and pressure control unit 7. The heat source of the heater comes from the thermal oil device 6. This device can ensure that the temperature and pressure of the thermal oil in the gas heater 4 work stably. Keep constant under the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com