Polypropylene coating material and preparation method thereof

A technology of polypropylene coating and polypropylene, which is applied in the direction of coating, etc., can solve the problems of increased shrinkage rate of extruded film, difficulty in heat sealing during processing, and impact on product quality, so as to achieve wider film width and reduce shrinkage phenomenon , Improve the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

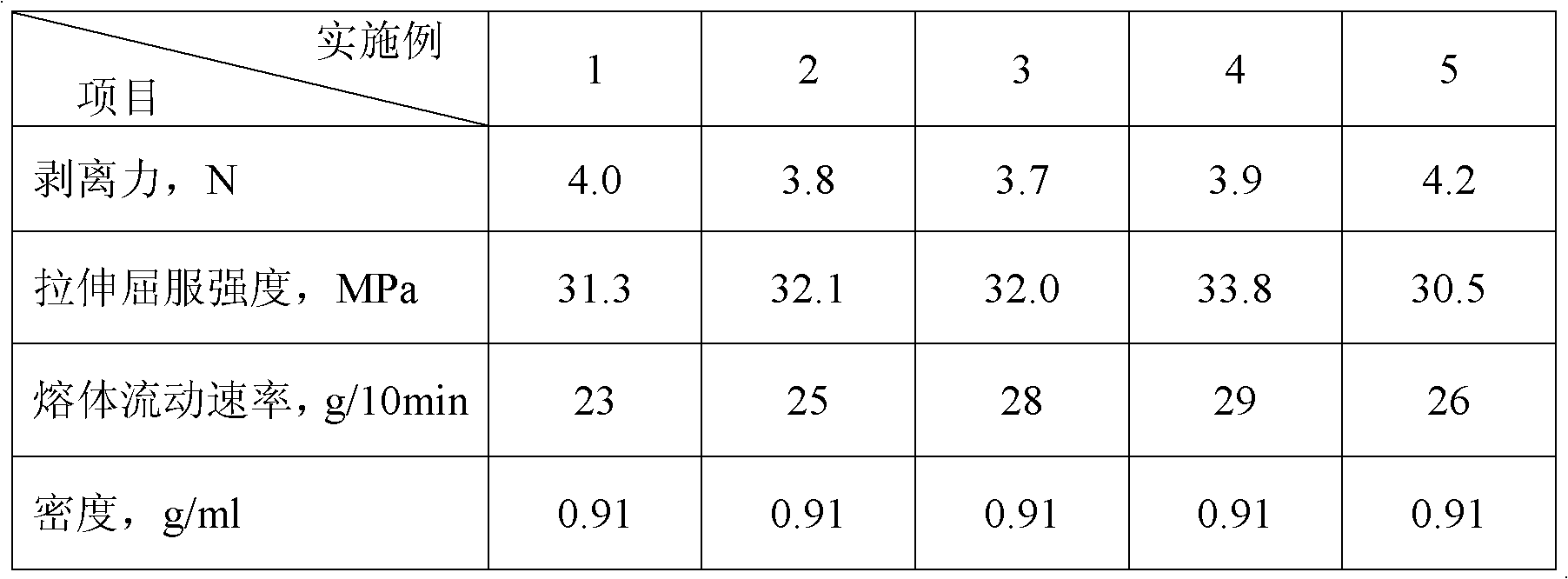

Embodiment 1

[0014] Embodiment 1: present embodiment polypropylene coating material, its component comprises: polypropylene powder 82 parts, surfactant (silicone oil) 0.8 part, acetone 1.0 part, lubricant (polyethylene wax CH-4 type) 0.8 part 10.8 parts of LDPE (1C7A), 4.5 parts of LLDPE (7042), 0.1 parts of polypropylene chemical degradation agent (2,5-dimethyl-2,5-di-tert-butylperoxyhexane), in parts by weight . All the above components are commercially available products.

[0015] In this embodiment, besides the lubricating effect, polyethylene wax also has the function of dispersion and material reinforcement. In addition to the CH-4 type used in this embodiment, CH-2, CH-3, CH-6, CH -9 type products.

[0016] In the present embodiment, the trade mark of the LDPE used is 1C7A (melt flow rate is 7g / 10min), has typicality, can also use 1C10A (melt flow rate is 10g / 10min);

[0017] In the present embodiment, the trade mark of the LLDPE used is 7042, is the common trade mark of LLDPE; ...

Embodiment 2

[0021] Embodiment 2: present embodiment polypropylene coating material, its component comprises: polypropylene powder 80.0 parts, surfactant (silicone oil powder) 1.2 parts, acetone 1.2 parts, lubricant (polyethylene wax CH-2 type) 0.5 parts, 11.3 parts of LDPE (1C7A), 4.8 parts of LLDPE (7042), 1 part of polypropylene chemical degradation agent (2,5-dimethyl-2,5-di-tert-butylperoxyhexane), in parts by weight count. All the above components are commercially available products.

[0022] The preparation method of polypropylene coating material is:

[0023] (1) After mixing the polypropylene powder, surfactant, acetone, lubricant and polypropylene chemical degradation agent of the weight portion at a high speed, utilize a single (twin) screw extruder to extrude, granulate and plasticize;

[0024] (2) Mix the mixture granules obtained in step (1) with the LDPE and LLDPE in said parts by weight to obtain a polypropylene coating material.

Embodiment 3

[0025] Embodiment 3: present embodiment polypropylene coating material, its component comprises: polypropylene powder 78 parts, surfactant (polyether modified silicone oil) 0.9 part, acetone 0.5 part, lubricant (polyethylene wax CH- Type 3) 0.6 parts, LDPE (1C7A) 20 parts, by weight. All the above components are commercially available products.

[0026] The preparation method of polypropylene coating material is:

[0027] (1) After mixing the polypropylene powder, surfactant, acetone and lubricant at a high speed of the weight portion, utilize a single (twin) screw extruder to extrude, granulate and plasticize;

[0028] (2) Mixing the mixture particles obtained in step (1) with the LDPE in parts by weight to obtain a polypropylene coating material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com