Large-amplitude-necking seamless forming process for stainless steel cup body

A molding process, stainless steel technology, applied in the direction of drinking water vessels, etc., can solve the problems of increased proportion of weld wear, low product vacuum pass rate, and failure to meet product process requirements, etc., to improve the vacuum pass rate and reduce shrinkage Amplitude, the effect of avoiding weld wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

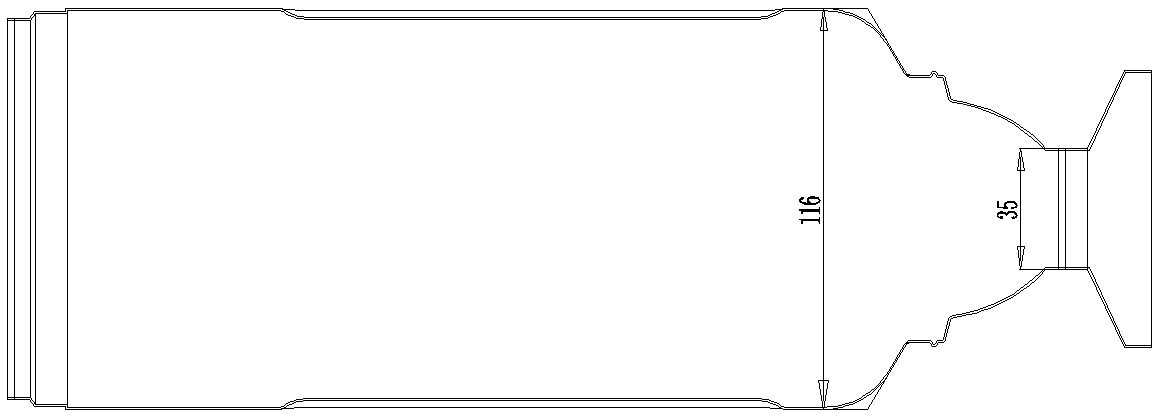

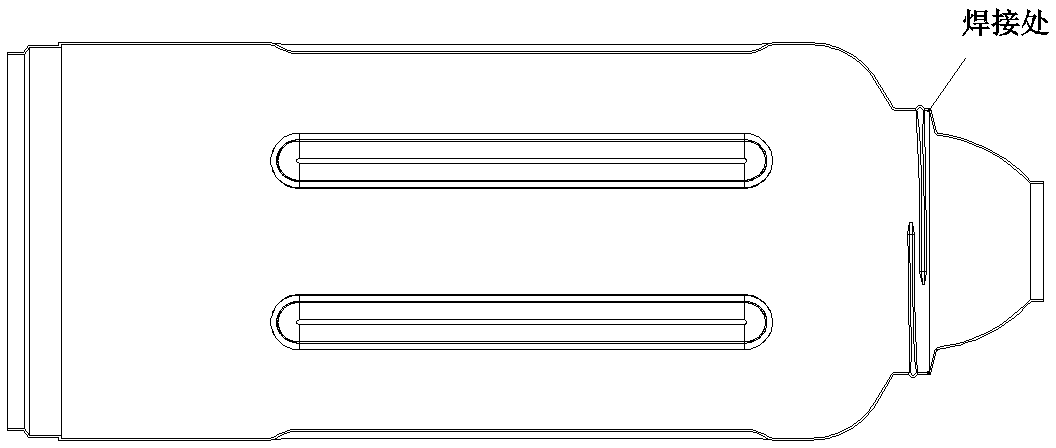

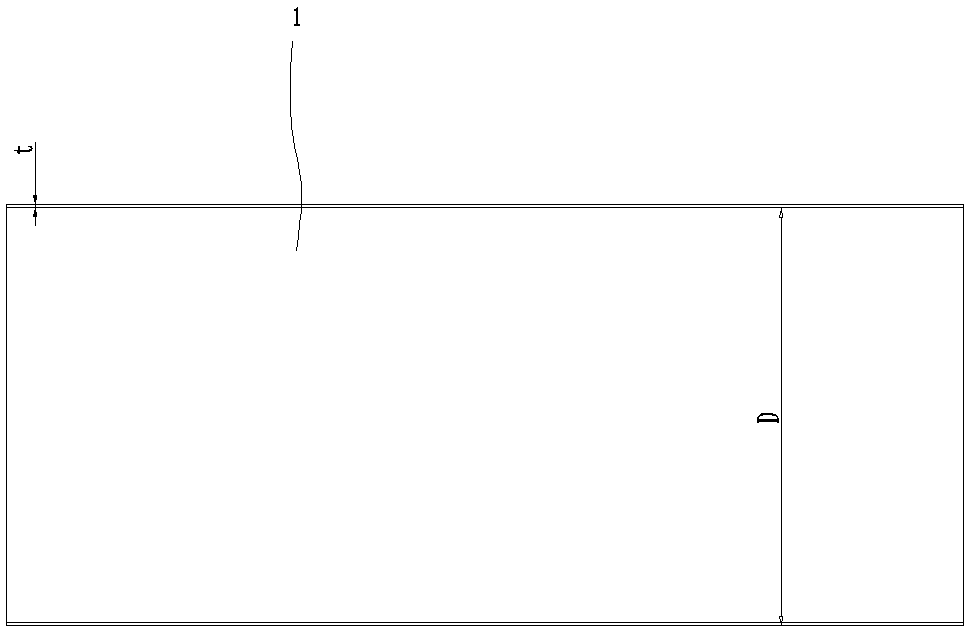

[0026] In order to make the technical solution of the present invention clearer, the following in conjunction with the attached Figures 1 to 8 , the present invention will be described in detail. It should be understood that the specific implementations described in this specification are only for explaining the present invention, and are not intended to limit the protection scope of the present invention.

[0027] The present invention is a large-needle seamless forming process of a stainless steel cup body, which is characterized in that it comprises the following steps:

[0028] Step 1: Cutting the round tube 1 for processing the stainless steel cup body, the outer diameter of the round tube 1 is D, and performing water medium hydroforming on the round tube 1 through the water expansion process, so that the round tube 1 forms the initial shape of the stainless steel cup body 1 -1; Step 2: Carry out gold processing on the upper, middle and lower sections of the initial sha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com