Self-balancing amplitude modulation holding pole

A self-balancing and pole-holding technology, applied in ships, cargo handling equipment, passenger handling equipment, etc., can solve the problems of inconvenient transportation on site, large number of parts, and high cost of purchase, transportation and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following will be described in conjunction with the accompanying drawings and specific embodiments.

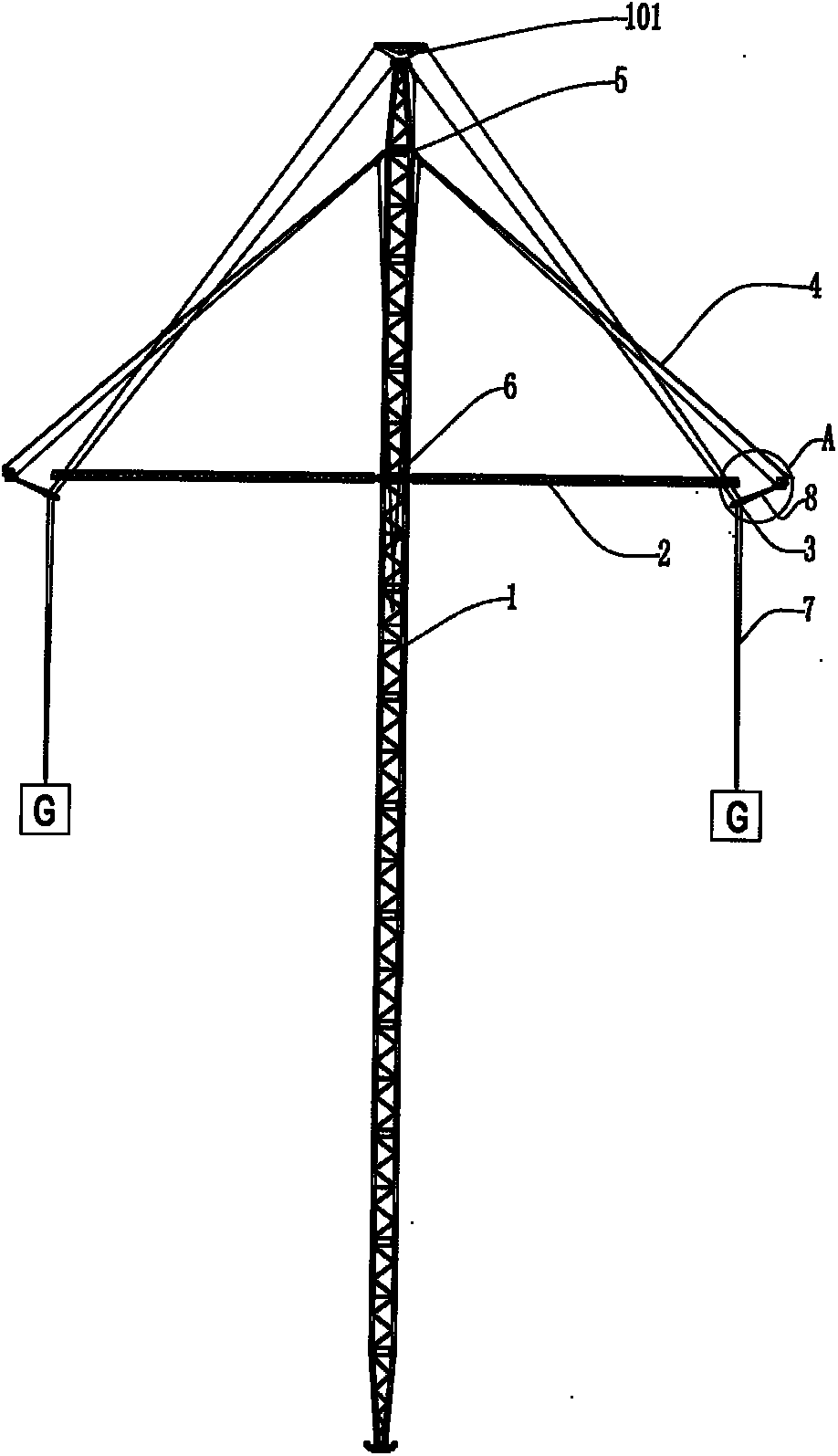

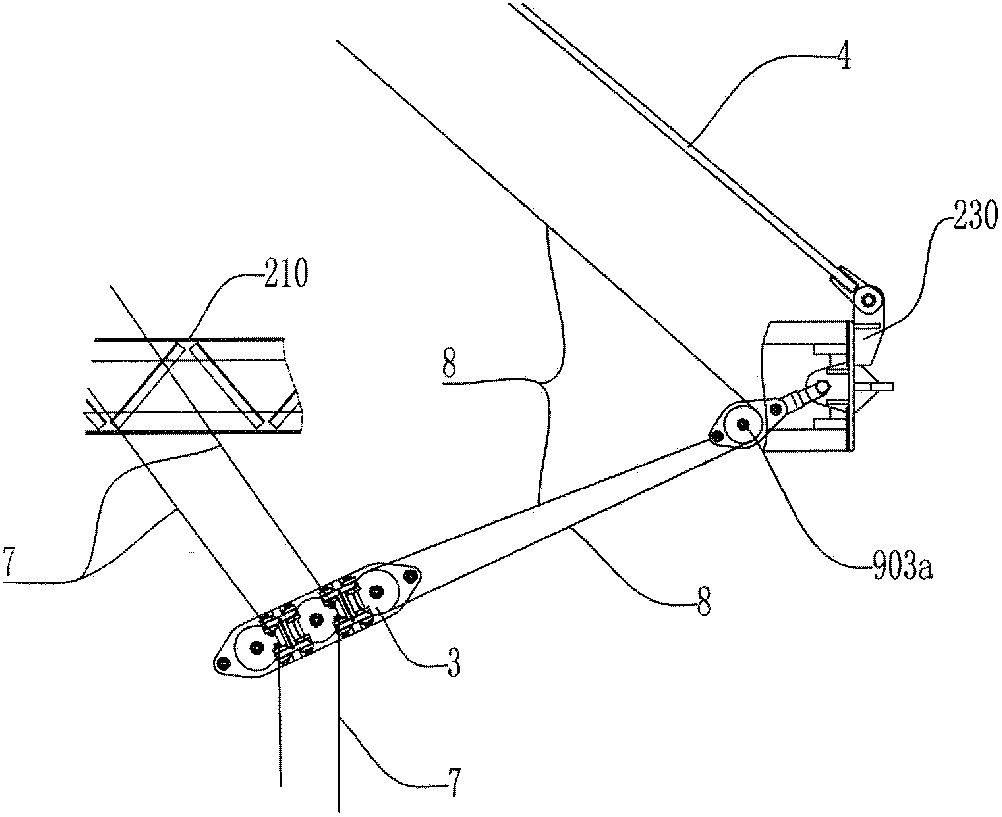

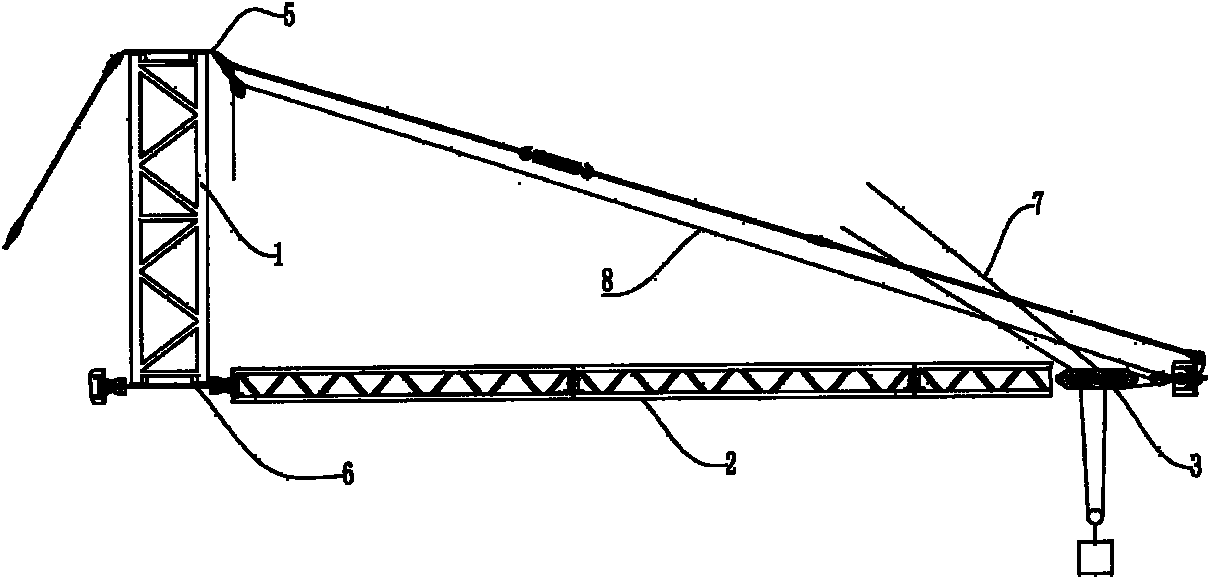

[0038] Picture 1-1 An overall example of a self-balancing AM pole is shown. see Figure 1-1 to Figure 3-2 , the main pole 1 is a circular tube type inner suspension pole, and the main pole is composed of multi-section lattice sections connected by bolts, as described in Chinese patent 200910058946.2. Booms 2 are symmetrically arranged on both sides of the upper and middle positions of the main pole 1 , and a claw arm assembly 101 is installed on the top of the main pole. Two pulleys are arranged on the top of the claw arm assembly 101 . A fixed block 901 is installed on the upper right side of the main pole 1, and the first amplitude modulation pulleys 902a and 902b are symmetrically installed on the main pole 1 below the fixed block 901; the boom 2 is hinged on the main pole, and the outer end of the boom 2 The second amplitude modulation block 903a, 903b is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com