Crankshaft oil wiper of internal combustion engine

A technology of oil scraper and internal combustion engine, applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problem of high exhaust gas pressure in the crankcase, achieve the effects of reducing exhaust gas pressure, simple process, and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

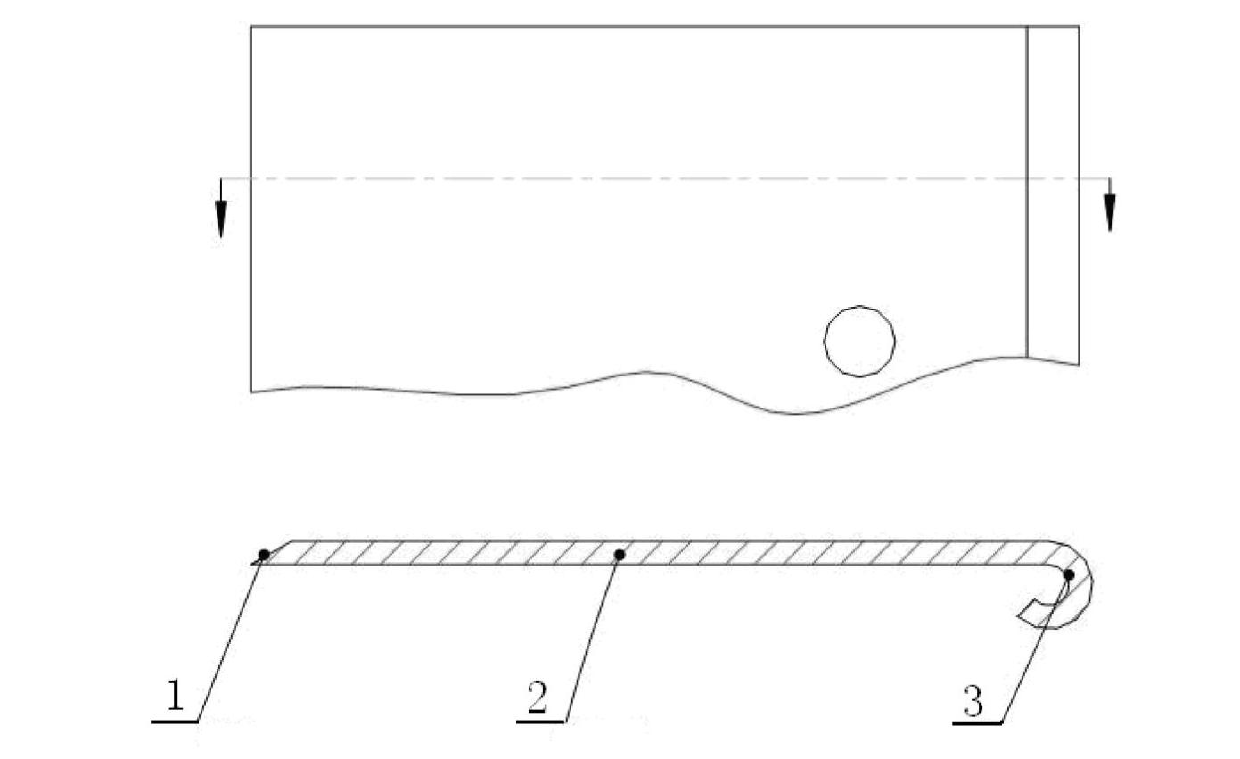

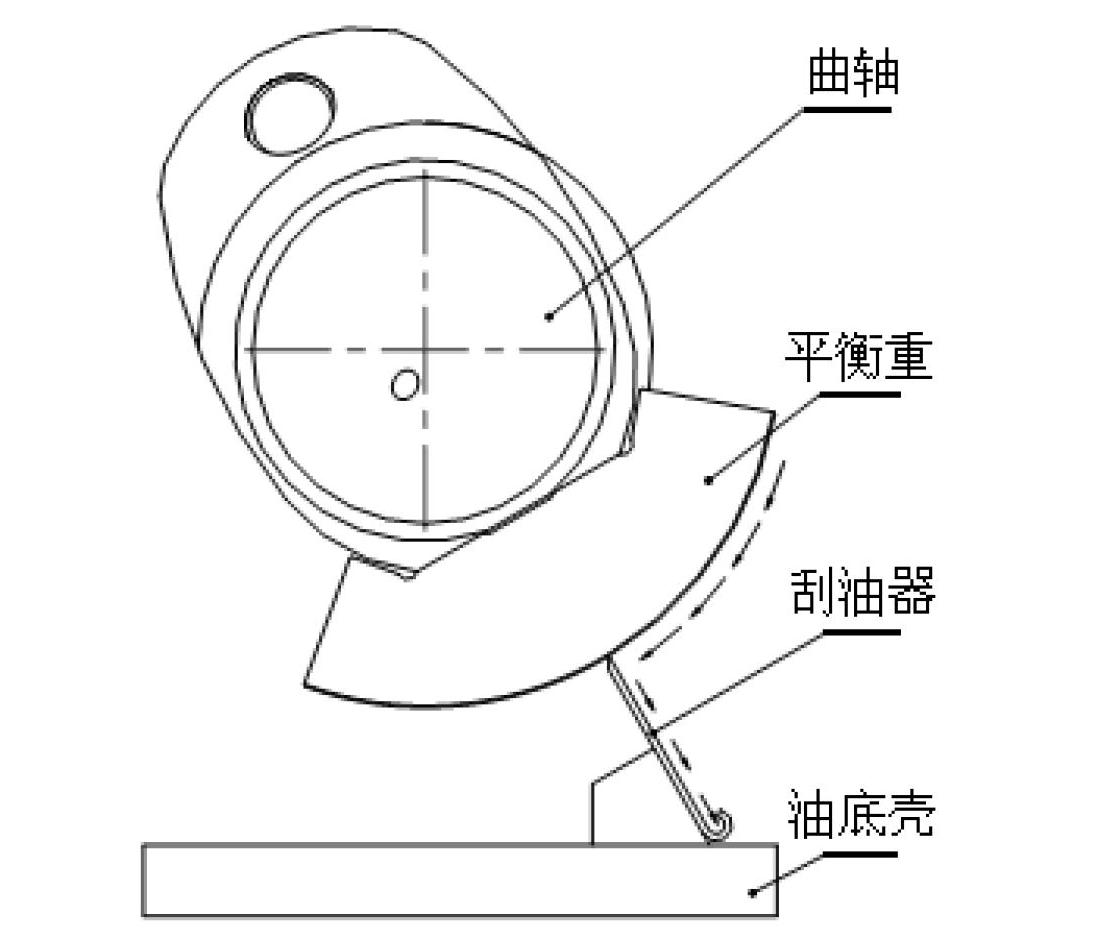

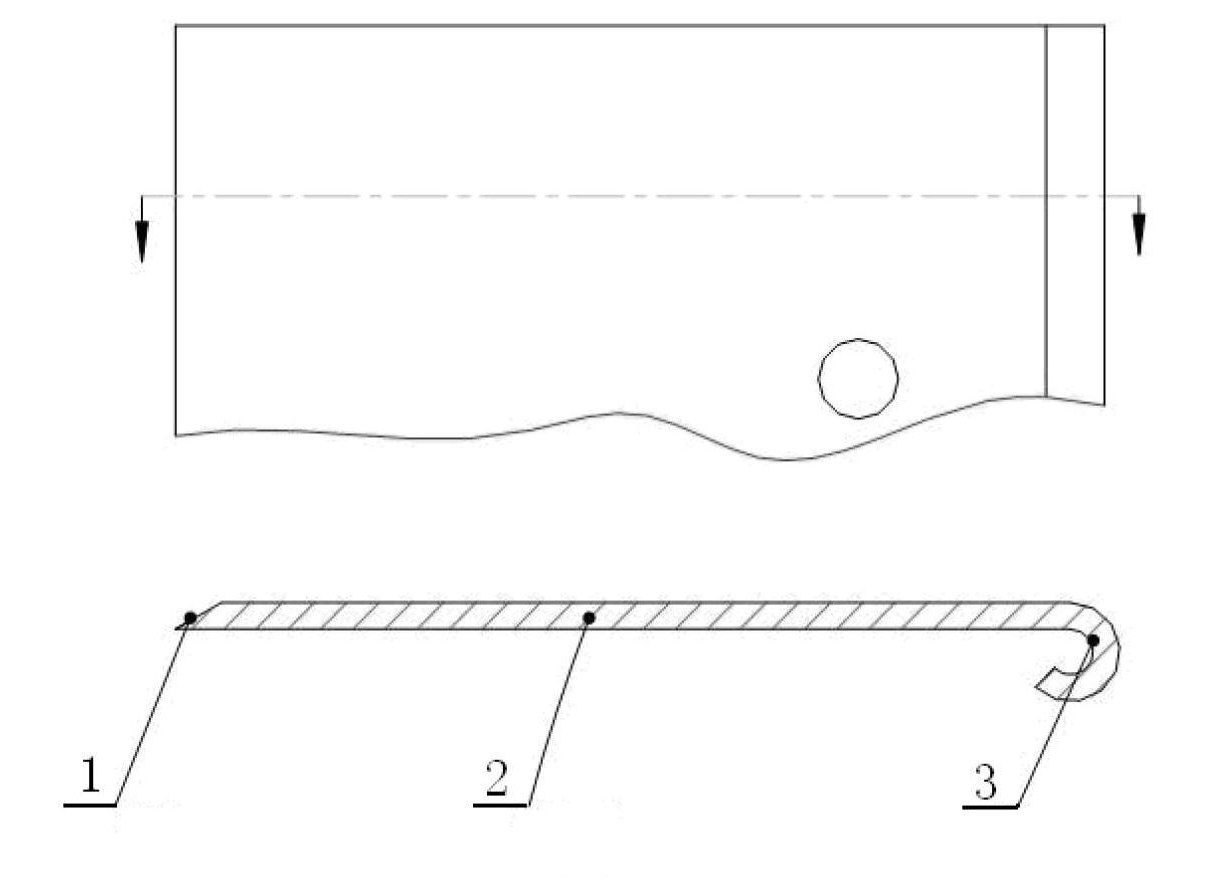

[0011] A crankshaft oil scraper for an internal combustion engine, including three parts: an oil scraper 1, a baffle plate 2, and a diversion groove 3. The oil scraper is a plate-shaped structure made of stainless steel, and the oil scraper is obliquely fixed on the oil pan On the top, it forms a fixed angle with the tangent direction of the crankshaft rotation and there is a gap with the crankshaft; there is an oil scraper 1 on the baffle 2, and the tip of the oil scraper 1 is in contact with the outer circumference of the balance weight, and the baffle 2 is located along the On the splashing path of oil droplets in centrifugal motion in the crankshaft rotation tangential direction, the end of the baffle plate 2 is provided with a diversion groove 3, and the front and rear oil pools of the oil pan are formed under the two ends of the diversion groove 3.

[0012] work process:

[0013] When the balance weight rotates through the oil scraper, the oil film attached to the balanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com