Manufacturing method of ultrathin heat-conducting patch and ultrathin heat-conducting patch

A production method and technology of heat conduction stickers, which are applied in indirect heat exchangers, lighting and heating equipment, cooling/ventilation/heating transformation, etc., can solve the problem of poor heat exchange capacity on the surface of ultra-thin heat conduction stickers and difficulties in effectively solving heat dissipation devices Heat dissipation problems, limited internal space of electronic products and other problems, to achieve the effect of shortening the heat dissipation time, improving the heat dissipation effect, and uniform and meticulous distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

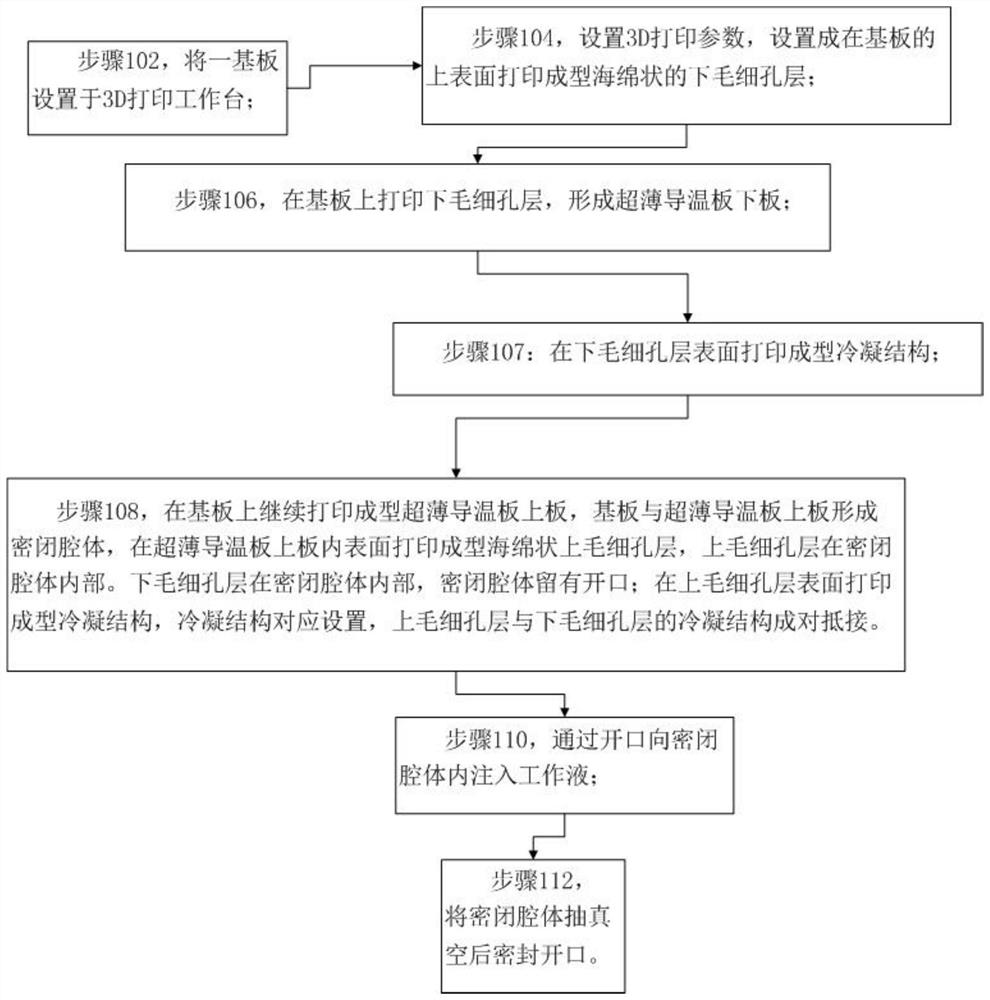

[0043] refer to figure 1 As shown, a manufacturing process of an ultra-thin heat conduction patch includes the following steps:

[0044] Step 102, setting a substrate on the 3D printing workbench;

[0045] Step 104, setting 3D printing parameters, and setting it to print and form a spongy lower capillary layer on the upper surface of the substrate;

[0046] Step 106, printing the lower capillary layer on the substrate to form the lower plate of the ultra-thin heat conduction patch;

[0047] Step 108, disposing an ultra-thin heat-conducting patch upper plate on the upper surface of the substrate, the substrate and the ultra-thin heat-conducting patch upper plate form a closed cavity, the lower capillary layer is inside the closed cavity, and the closed cavity has an opening;

[0048] Step 110, inject working fluid into the sealed cavity through the opening;

[0049] Step 112, vacuumize the closed cavity and then seal the opening.

[0050] With this implementation method, th...

Embodiment 2

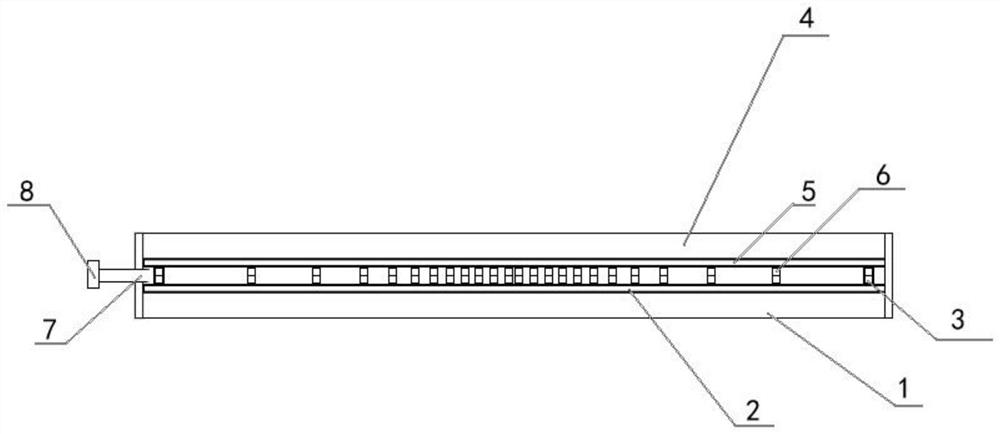

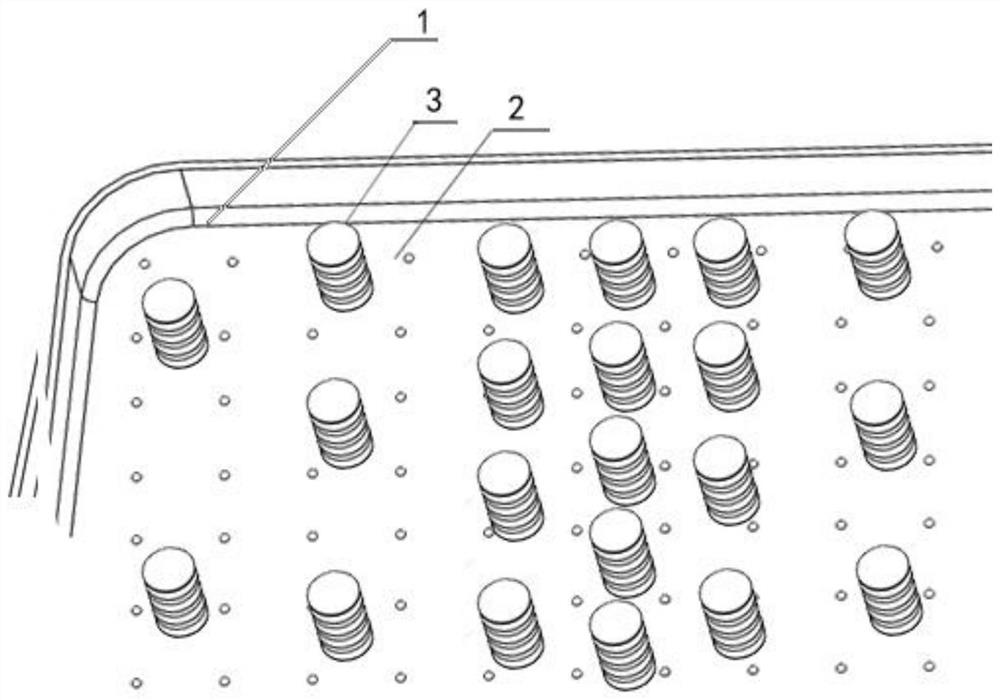

[0068] refer to figure 2 , an ultra-thin heat conduction patch, including a substrate 1, a lower capillary layer 2, a condensation structure 3, an upper plate 4 of the ultrathin heat conduction patch, an upper capillary layer 5, a condensation structure 6, an opening 7, and a sealing valve 8. Print the lower capillary layer 2 on the substrate 1 to form the lower plate of the ultra-thin thermal conductive patch; continue to print and form the upper plate 4 of the ultra-thin thermal conductive patch on the substrate 1, and the substrate 1 and the upper plate 4 of the ultra-thin thermal conductive patch form a closed cavity body, on the inner surface of the ultra-thin heat-conducting patch upper plate 4, print and form a spongy upper capillary layer 5, and the upper capillary layer 5 is inside the closed cavity. The lower capillary layer 2 is inside the closed cavity, and the closed cavity has an opening 7; the condensation structure 6 is printed and formed on the surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com