Open slot type LED (Light-emitting Diode) flexible neon lamp

A neon light and flexible technology, applied in the field of slotted LED flexible neon lights, can solve problems such as low production efficiency, affecting product quality, and inability to guarantee product quality, so as to achieve the effect of ensuring quality and reducing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

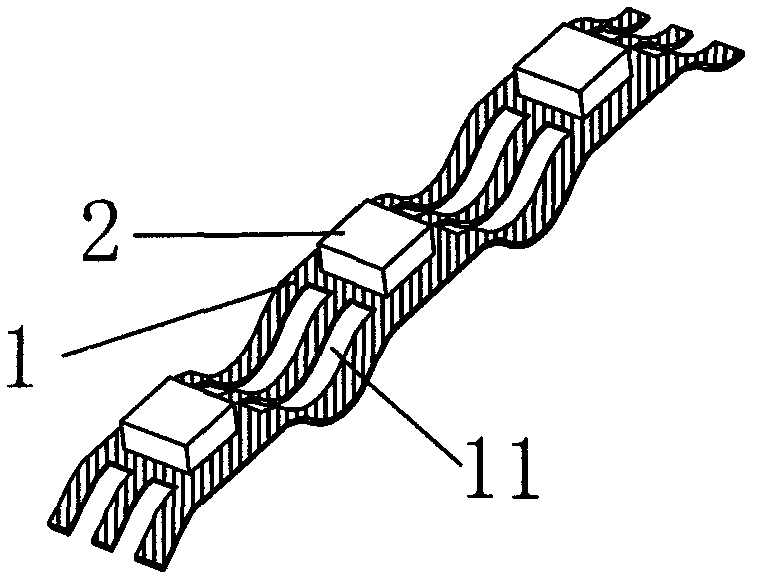

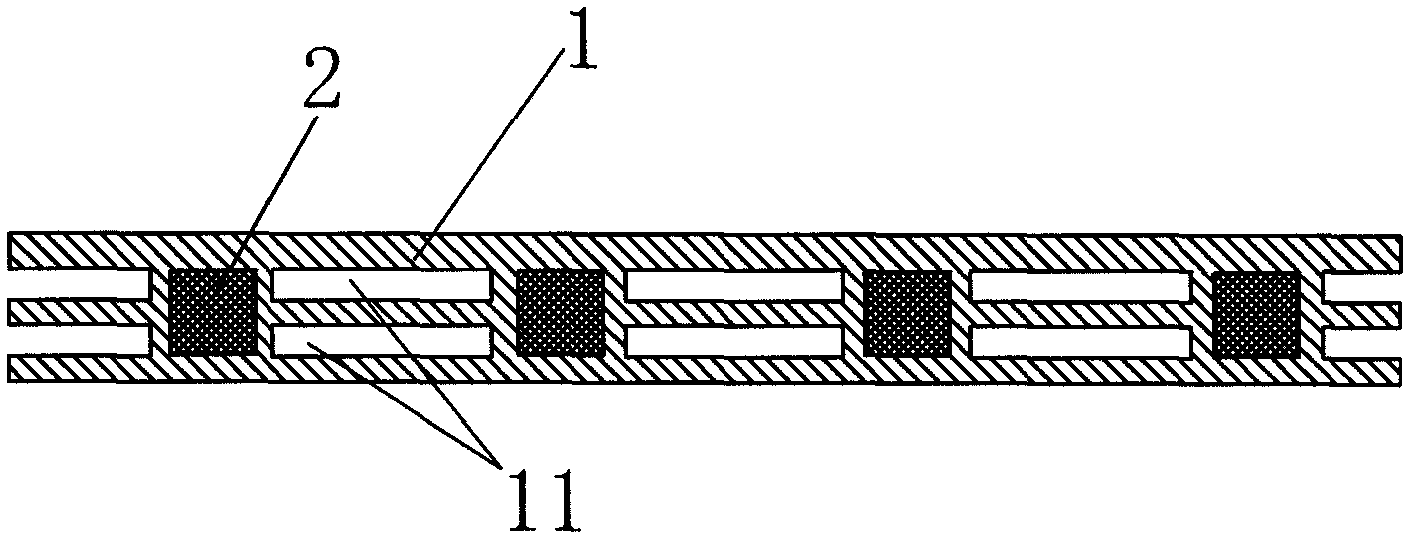

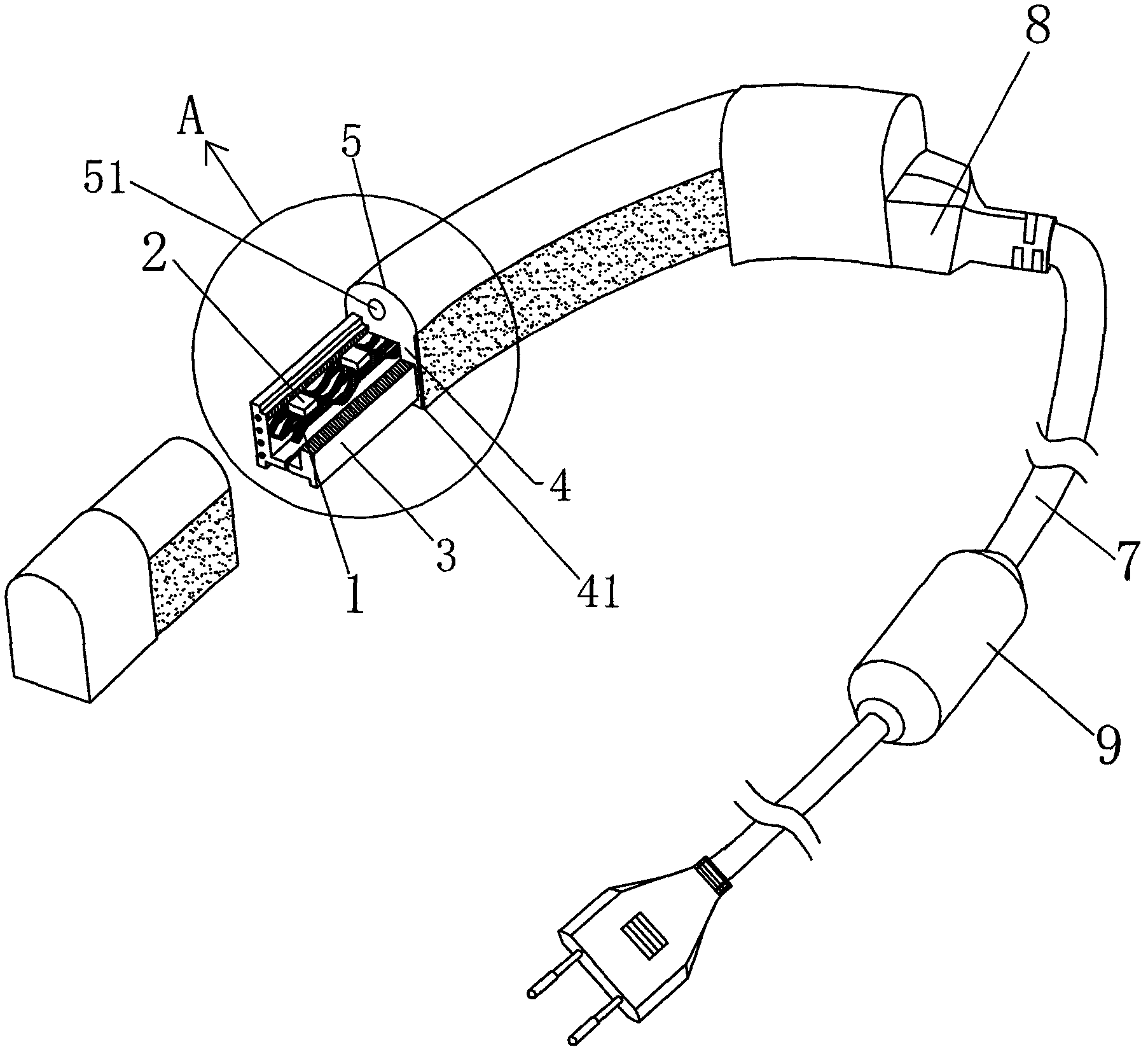

[0037] refer to figure 1 and figure 2 , a slotted LED flexible neon light of the present invention, comprising a strip-shaped flexible circuit board 1, LED2 arranged on the strip-shaped flexible circuit board 1, and a covering layer arranged on the periphery of the strip-shaped flexible circuit board 1 and LED2, said The strip-shaped flexible circuit board 1 includes a conductive area and a non-conductive area. The non-conductive area of the strip-shaped flexible circuit board 1 is provided with an opening slot 11 , and the opening slot 11 runs through the strip-shaped flexible circuit board 1 .

[0038] The opening slot 11 is arranged in the non-conductive area between two adjacent LEDs 2 on the strip-shaped flexible circuit board 1 , the opening slot 11 is in the shape of a long strip, and the number of the opening slot 11 is one or more than one. A plurality of strip-shaped flexible circuit boards 1 may be arranged in the covering layer, and the plurality of flexible ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com