Ore heating furnace

A submerged arc furnace and furnace cover technology, applied in the field of smelting, can solve the problems of heat loss, safety reduction, lack of heat insulation materials in the furnace body, etc., to improve thermal efficiency, ensure safe and reliable operation, and reduce heat dissipation and radiation on the surface of the furnace body The effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

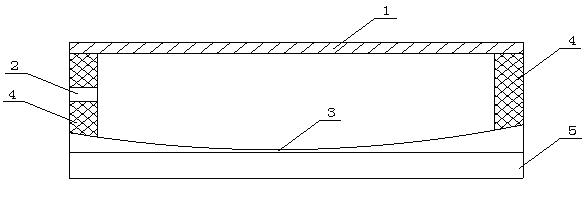

[0015] Such as figure 1 As shown, the present embodiment provides a submerged arc furnace, the body of the submerged arc furnace is composed of a furnace cover 1, a furnace door 2, a launder 3, a furnace wall 4 and a furnace bottom 5, wherein the furnace cover 1 and the furnace door 2 The inner lining is made of aluminum oxide hollow ball castables; the launder 3 is made of graphite, the furnace wall 4 is made of corundum fired bricks, and the furnace bottom 5 is made of corundum castables.

[0016] This embodiment is suitable for smelting white corundum.

Embodiment 2

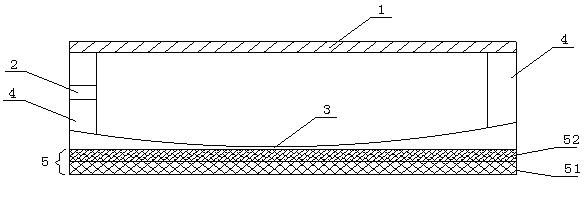

[0018] Such as figure 2 As shown, the present embodiment provides a submerged arc furnace, the body of the submerged arc furnace is composed of a furnace cover 1, a furnace door 2, a launder 3, a furnace wall 4 and a furnace bottom 5, wherein the furnace cover 1 and the furnace door 2 The inner lining is made of corundum hollow ball castable; the launder 3 is made of graphite, the furnace wall 4 is made of corundum fired bricks, and the furnace bottom 5 is composed of a light heat insulation layer 51 and a dense working layer 52. The dense working layer 52 is casted with corundum castable, and the light heat insulation layer 51 is casted with corundum hollow ball castable.

[0019] This embodiment is suitable for smelting brown corundum.

Embodiment 3

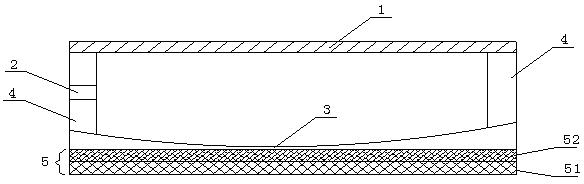

[0021] Such as figure 2 As shown, the present embodiment provides a submerged arc furnace, the body of the submerged arc furnace is composed of a furnace cover 1, a furnace door 2, a launder 3, a furnace wall 4 and a furnace bottom 5, wherein the furnace cover 1 and the furnace door 2 The inner lining is made of zirconia hollow ball castable; the launder 3 is made of water-cooled steel plate, the outer side of the steel shell of the furnace wall 4 adopts an external spray cooling structure, and the furnace bottom 5 is composed of a light heat insulation layer 51 and a dense working layer 52, the dense working layer 52 is made of zircon sand ramming material, and the light heat insulation layer 51 is casted from zirconia hollow ball castable material.

[0022] This embodiment is suitable for smelting zirconia.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com