Method for manufacturing piezoelectric interlinings

A manufacturing method and interlayer technology, which are used in material analysis, measuring devices, and instruments using sonic/ultrasonic/infrasonic waves, which can solve the problem of low connection strength, "island" electrodes that are easy to fall off, and difficult to play a protective role, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

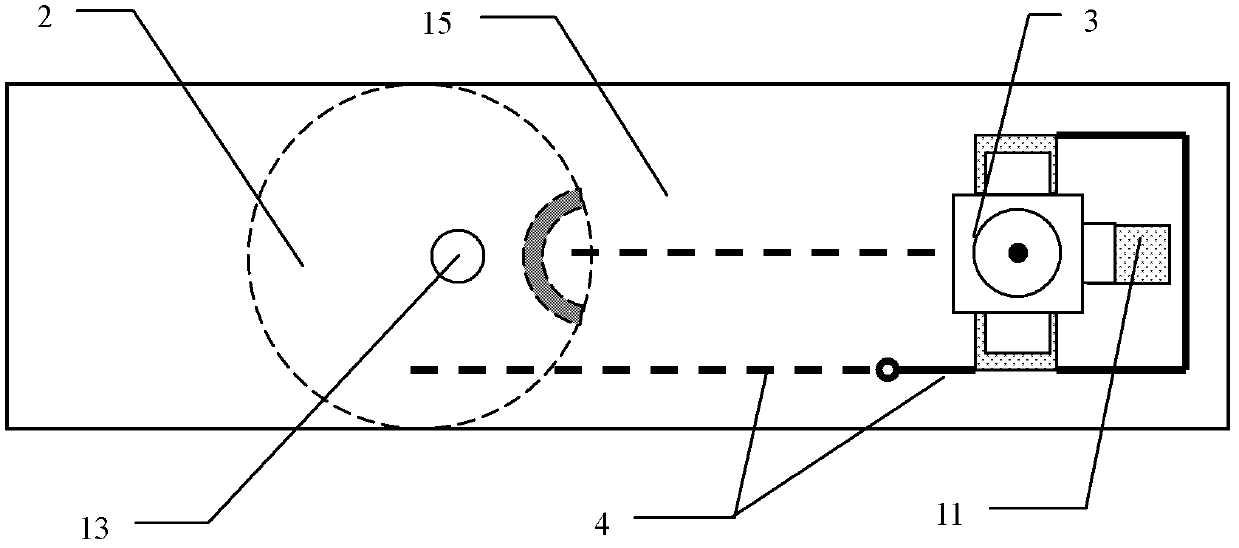

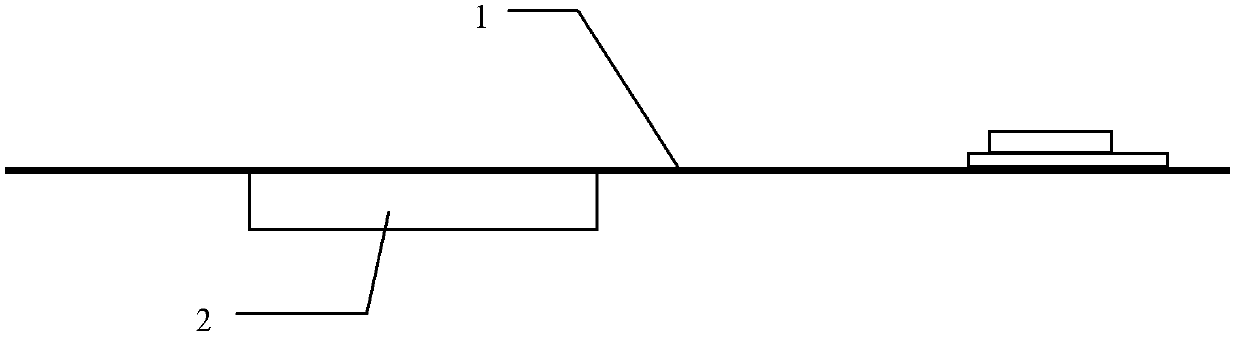

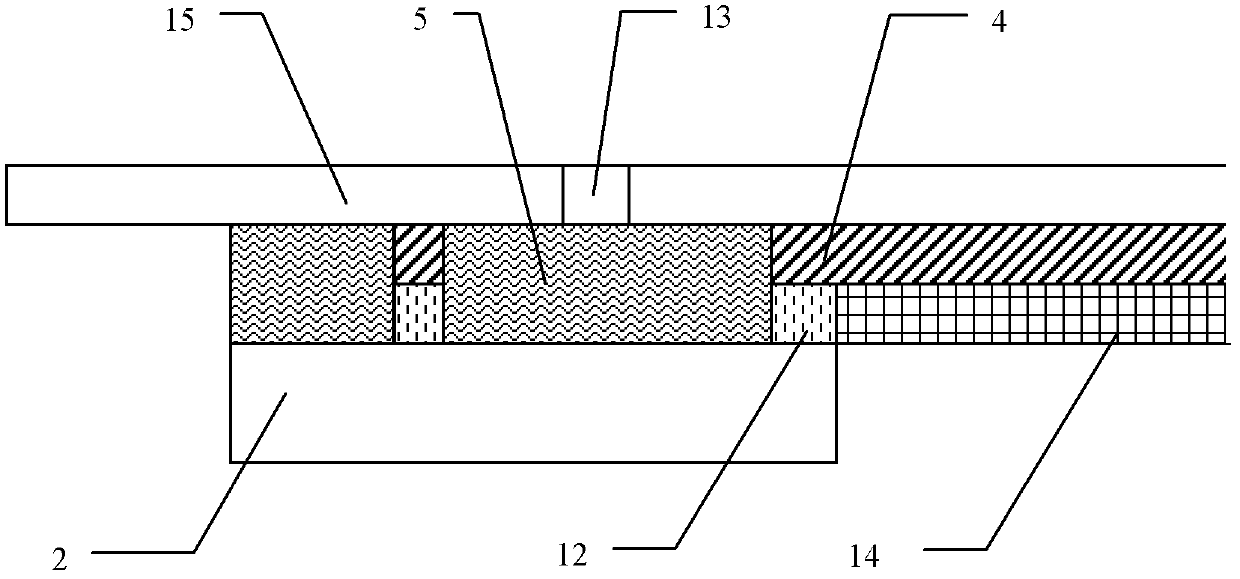

[0020] The implementation process of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0021] The invention provides a method for manufacturing a piezoelectric interlayer, which is used to make a piezoelectric interlayer by using a flexible circuit board, a piezoelectric sheet and a general interface, and the piezoelectric sheet is used as an actuator / sensor element, specifically comprising the following steps:

[0022] (1) Reserve the position of the circuit pad on one side of the flexible circuit board according to the electrode position of the piezoelectric sheet, and reserve the position of the pin pad of the general interface on the other side of the flexible circuit board, and then place the flexible circuit board The remaining areas of the board are all covered with an insulating layer to prevent short circuits during use;

[0023] (2) Establish a circuit connection between the pin pad on the flexible circuit board ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com