Electrolytic tank integrated structure based on alkaline water electrolysis hydrogen production process

An electrolyzer and electrolyzed water technology, applied in the field of electrolyzers, can solve the problems of cumbersome and time-consuming disassembly and replacement of electrodes and electrolyzers, and affect the efficiency of hydrogen production, so as to achieve convenient disassembly, prolong service life, and improve frictional fastening degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

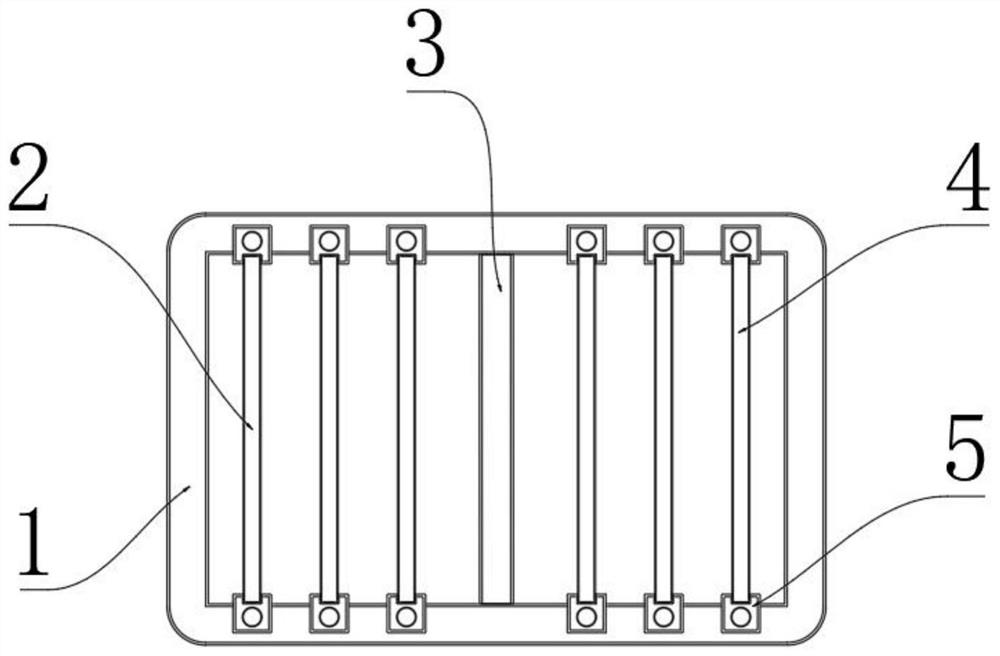

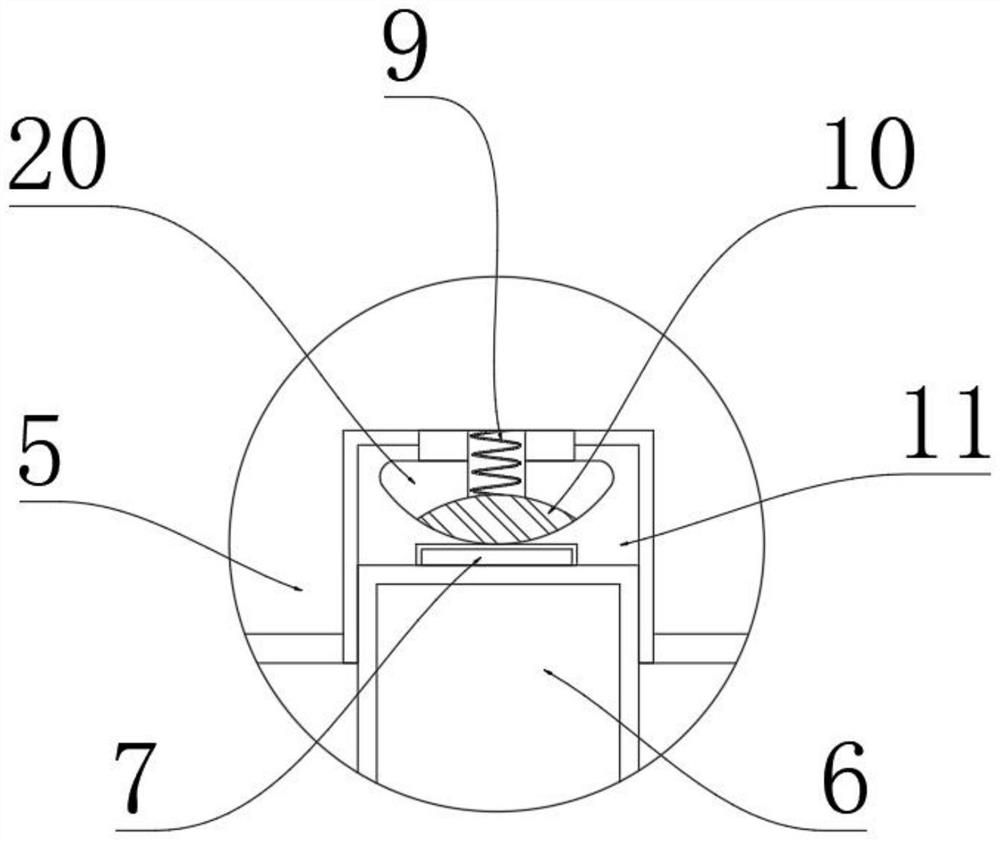

[0027] Please refer to figure 1 , image 3 and Figure 5 As shown, the present invention provides an electrolytic cell integrated structure based on alkaline electrolyzed water hydrogen production process, comprising an electrolytic cell body 1, a first pole plate 2, a second pole plate 4 and a diaphragm 3, the first pole plate The sheet 2 is arranged on one side of the electrolytic cell body 1, the electrolytic cell body 1 is arranged on the other side of the electrolytic cell body 1, and the diaphragm 3 is isolated on the first plate sheet inside the electrolytic cell body 1 2 and the second pole plate 4, the first pole plate 2 and the second pole plate 4 are the positive pole and the negative pole respectively, or the first pole plate 2 and the second pole plate 4 are the negative pole and the positive pole respectively, The inner side wall of the electrolytic cell body 1 is connected and fixed with a square column 5, and a guide chute 11 is provided axially from the squa...

Embodiment 2

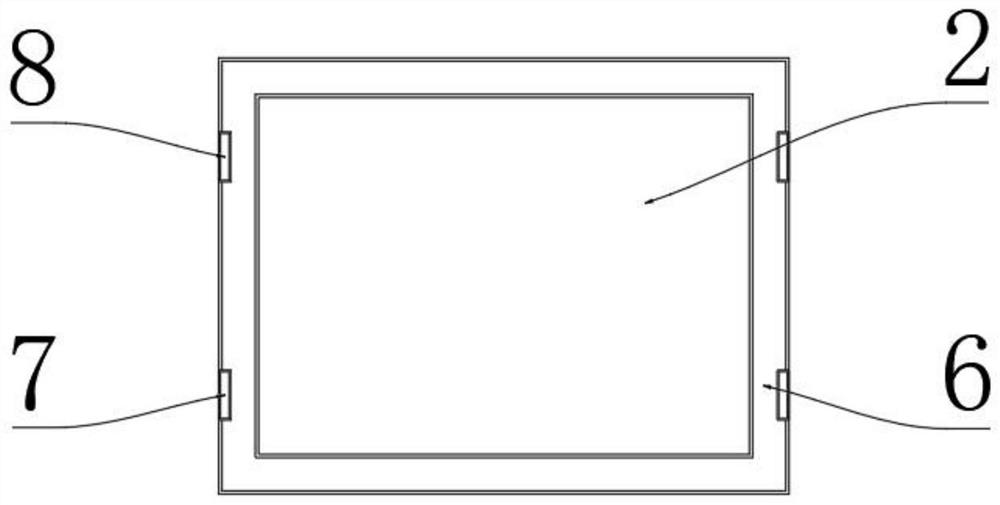

[0030] Such as figure 1 , figure 2 and image 3 As shown, the present invention discloses that the inner side wall of the electrolytic cell body 1 is connected and fixed with a square column 5, and a guide chute 11 is provided axially from the square column 5 to the top, and the side wall of the guide chute 11 is connected with an electrode conductive contact. Point 10, the side walls of the first pole plate 2 or the second pole plate 4 are slidingly engaged with the guide chute 11, and the side walls of the first pole plate 2 and the second pole plate 4 are covered An outer frame 6 is provided, and the side wall of the outer frame 6 is connected with a conductive piece 7, and the inner end of the conductive piece 7 is electrically connected with the first plate piece 2 or the second plate piece 4, and the end of the conductive piece 7 is electrically connected. The outer end and the electrode conductive contact 10 are in contact with each other. The electrode conductive co...

Embodiment 3

[0032] Such as figure 1 , figure 2 and Figure 4As shown, the present invention discloses that the inner side wall of the electrolytic cell body 1 is connected and fixed with a square column 5, and a guide chute 11 is provided axially from the square column 5 to the top, and the first plate piece 2 or the second plate piece 4 The side walls of the outer frame 6 are all slided and engaged with the guide chute 11, the inner wall of the guide chute 11 is provided with a movable groove 14, and the side wall of the outer frame 6 is provided with a positioning groove 16 relative to the movable groove 14, and the movable groove 14 and the positioning groove A steel ball 15 is clamped between 16, and the outer port of the movable groove 14 is covered with a limit ring 13. The diameter of the inner hole of the limit ring 13 is between the radius and diameter of the steel ball 15, and the steel ball 15 is movably arranged on the movable Inside the groove 14, the inner inner wall of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com