Transshipping tank with stirring function

A technology of function and stirring head, applied in the field of transfer tank, to achieve the effect of convenient overall arrangement, less manpower requirement and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

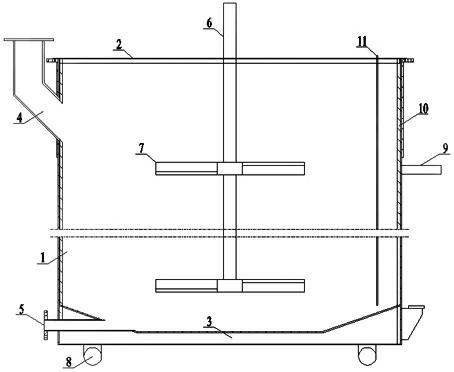

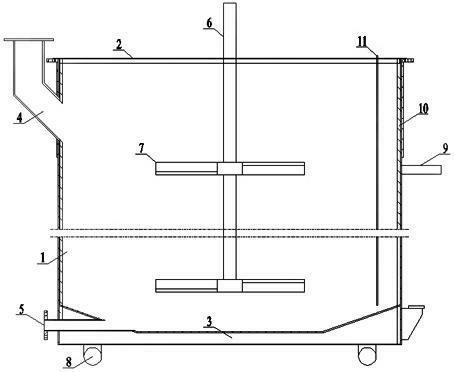

[0020] Such as figure 1 A transfer tank with a stirring function is shown, comprising a tank body 1, a tank cover 2, and a tank bottom 3. The tank body 1 is provided with a liquid inlet and outlet 4, and the tank body 1 is provided with a thermal insulation layer 11, wherein, A stirring head 6 is also included, and the stirring head 6 is pierced through the tank cover 2 . The transfer tank has the function of stirring and thermal insulation, and can replace the crystallization tank for stirring and crystallization reaction, and the crystallization tank is left empty to process subsequent batches, so as to improve the equipment utilization rate of the crystallization tank; and interlayers or The cargo rack is placed in the transfer slot, which is convenient for making full use of the storage space. Storing the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com