Intelligent brushing, sweeping and rapping device for high voltage electrostatic precipitator tail electric field

A technology of high-voltage electrostatic and rapping device, which is applied to the device for cleaning dust, and the field of intelligent brushing and rapping device at the tail of high-voltage electrostatic precipitator, which can solve the problems of back corona, secondary dust, and increase in outlet emissions , to achieve the effect of cleaning the dust thoroughly and reducing the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

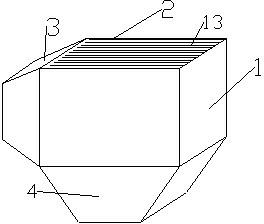

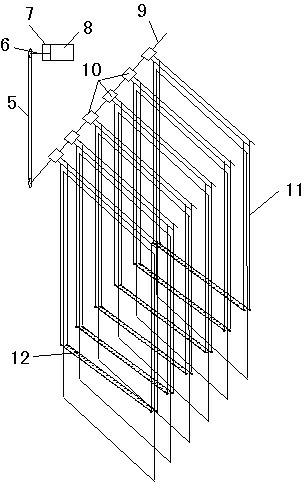

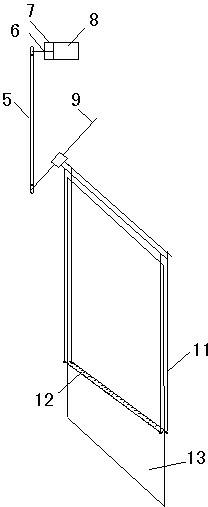

[0027] Such as figure 1 , 2 , 3, 4, 5, 6, 7, and 8, a high-voltage electrostatic precipitator tail electric field intelligent brush sweeping and vibrating device, including a soot blower, a dust suppression plate electrode voltage drop device, a negative pressure suction device, a dust Inlet 1, dust cleaning chamber 2 connected with dust inlet 1 and equipped with anode plate 13 and cathode plate, air outlet bin 3 connected with dust cleaning chamber 2, and dust collector ash hopper 4 arranged at the bottom of dust cleaning chamber 2 , the two sides of the anode plate 13 are provided with wire brushes 12, and the wire brushes 12 are fixedly installed on the square steel 16. 9 are connected, the connecting rod 9 is connected with the electromagnetic clutch 6 through the transmission chain 5, the electromagnetic clutch 6 is connected with the reducer 7, and the reducer 7 is connected with the motor 8; Dust secondary treatment device.

[0028] The dust secondary treatment devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com