Intelligent rail forming machine and its control method

A molding machine and guide rail technology, applied in automatic control devices, manufacturing tools, metal processing machinery parts, etc., can solve problems such as difficulty in reflecting product price advantages, high product cost pressure, and increased product cost, shortening the production cycle, Ensure production quality and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

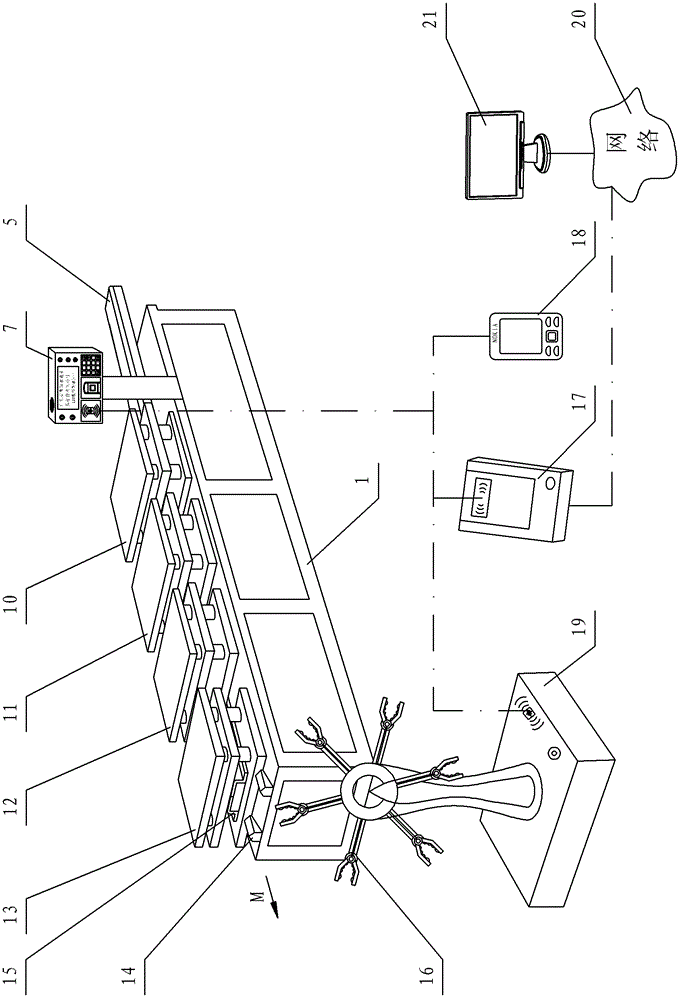

[0026] see Figure 1-Figure 4 , the intelligent guide rail forming machine includes a frame 1, a workbench is arranged on the frame 1, a guide mechanism 14 for transporting products 15 is arranged on the workbench, and a guide mechanism 14 for picking and placing is arranged beside the frame 1 Delivery product 15 manipulator 16.

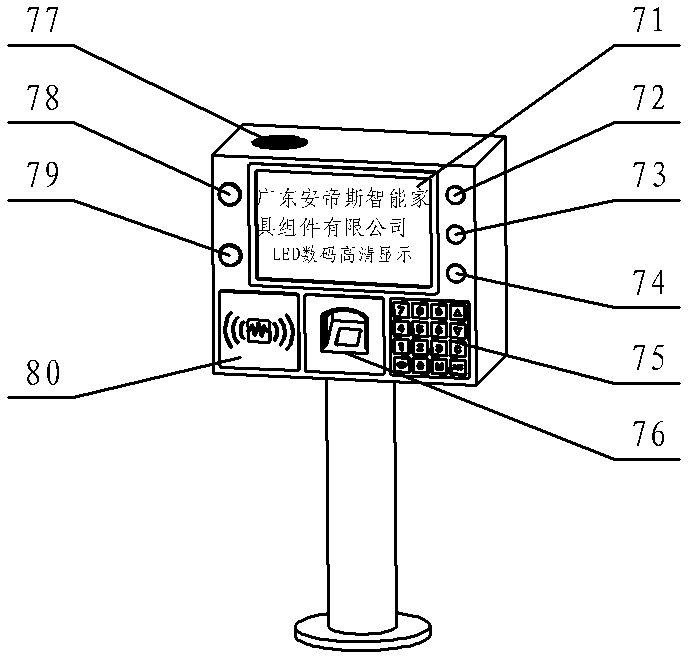

[0027] The manipulator 16 is arranged on the steering wheel 31 through the manipulator base plate 33 , and the steering wheel 31 is arranged on the manipulator console 19 through the manipulator bracket 32 .

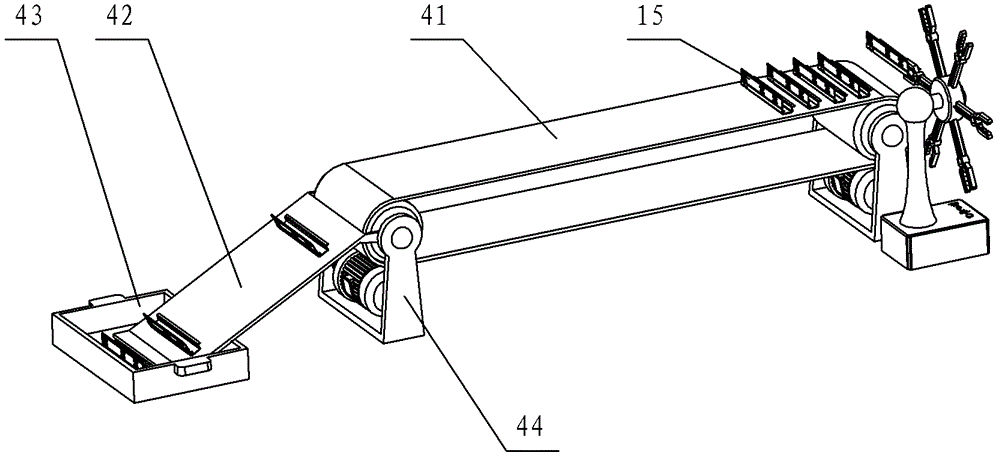

[0028] The frame 1 is provided with a feeding mechanism next to it, and the feeding mechanism includes a feeding belt 41 that is arranged on the side of the manipulator 16 for conveying the product 15. One end of the belt 41 is provided with a discharge belt 42 , and a packaging box 43 is provided below the discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com