Hot-pressing covering machine for facing wood lines

A cladding machine and wood molding technology, which is applied to wood processing appliances, household components, flat products, etc., can solve the problems of complicated operation, piercing of veneer sheets, and many processes, so as to reduce production costs and eliminate wrinkling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

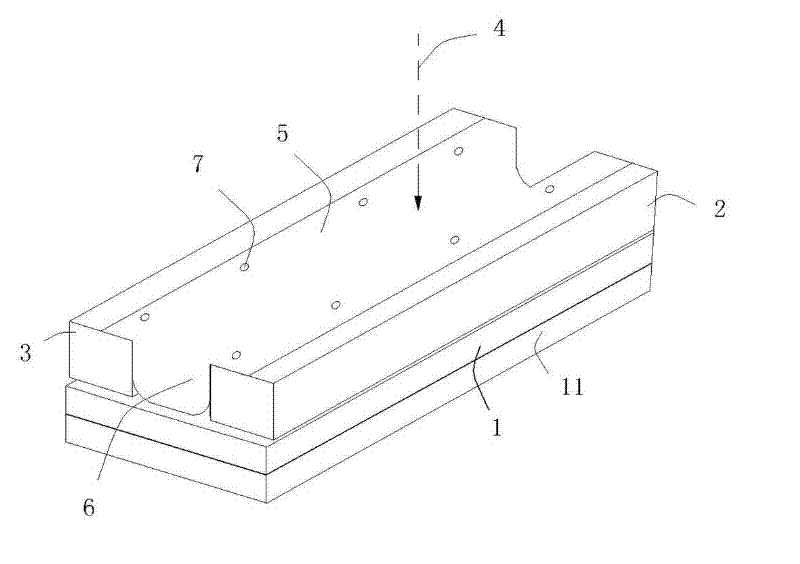

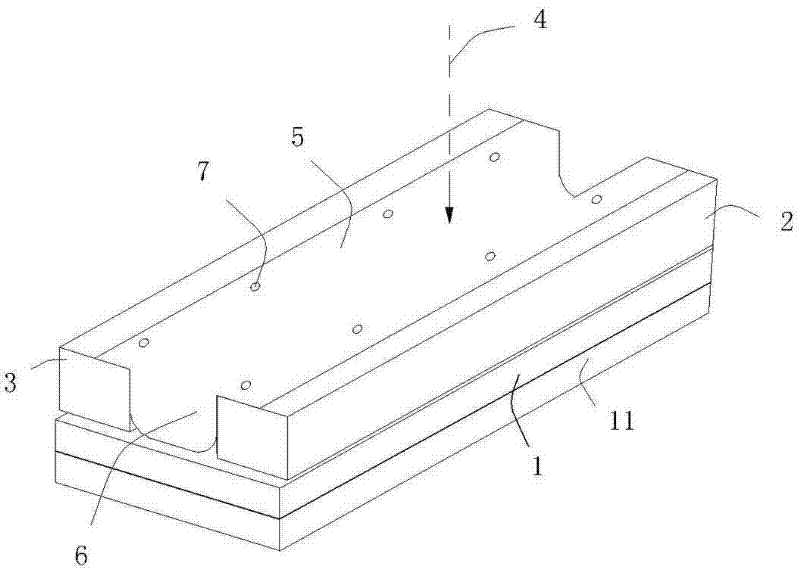

[0014] The overall structure of this veneer molding hot-press coating machine includes a frame, an electromechanical control box arranged on the frame, and a hydraulic system that makes the upper mold and the left and right side molds 2 and 3 reciprocate relative to the molding cavity 6. system, the mold and its heat transfer oil system for heating the lower mold and the left and right side molds, etc. Since except for the mold structure, the rest of the parts are technical structures that are easy to understand, so no more details will be given here. Only the mold part will be further elaborated below.

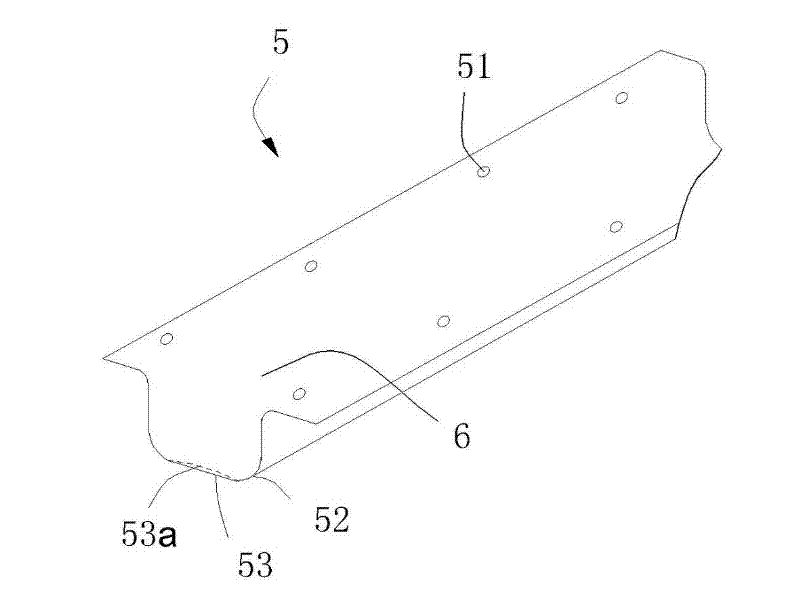

[0015] see figure 1 and combine figure 2 . The mold of this cladding machine is made up of upper mold, lower mold 1, side mold 2 and 3, the length of mold can be determined according to needs, and heat conduction oil circuit is set on lower mold 1, side mold 2 and 3. In general, the lower die 1 is horizontally detachable and fixedly arranged on the mold base 11 of the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com