High-heat-resistance, low-odor and flame-retardant high-impact polystyrene (HIPS) composition and preparation method thereof

A flame-retardant high-impact polystyrene, low-odor technology, applied in the field of high-heat-resistant, low-odor high-impact polystyrene composition and its preparation, can solve the problem of affecting the quality of polymer materials Widely used, no specific molecular sieve found Problems such as heat resistance, limited range of adsorption volatile matter and limited effect, to meet the requirements of environmental trends, reduce unpleasant feeling, and lower cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

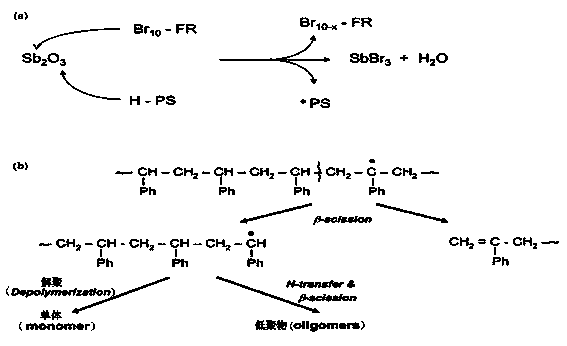

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following examples are provided to specifically describe the present invention, it is necessary to point out that the following examples are only used to further illustrate the present invention, and can not be interpreted as limiting the protection scope of the present invention, those skilled in the art according to the present invention SUMMARY OF THE INVENTION Some non-essential improvements and adjustments made to the present invention still belong to the protection scope of the present invention.

[0030] Table 1 Properties of selected molecular sieves

[0031] SiO 2 / Al 2 o 3 (mol) Specific surface area (m 2 / g) Pore volume (cm 3 / g) Aperture (nm) Molecular sieve 1 2 740 0.36 0.2-0.4 Molecular sieve 2 3 740 0.36 0.4-1.0 Molecular sieve 3 10 680 0.64 0.5-2.0 Molecular sieve 4 30 850 0.96 2.0-10.0

[0032] Table 2 Formula composition and content

[0033] component name Example 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com