Heat treatment method for improving mechanical property of low-carbon hardened and tempered steel

A heat treatment method, quenched and tempered steel technology, applied in the field of heat treatment, can solve the problems of severe plate thickness effect, poor hardenability, large fluctuations in mechanical performance indicators such as strength and impact toughness, etc., to improve comprehensive mechanical properties and improve mechanical properties The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

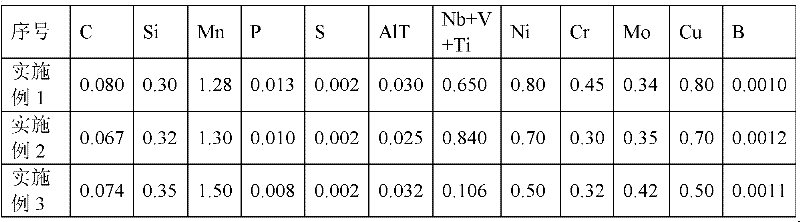

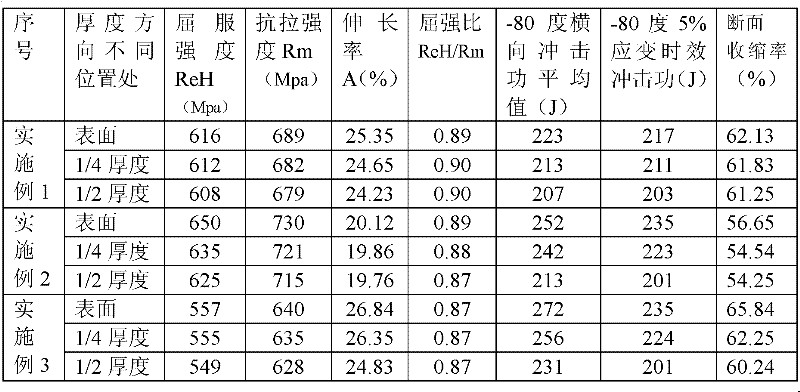

[0011] Embodiment 1: the quenching temperature of the rolled steel plate is 860 degrees, the heating rate is 1.5min / mm, and the holding time is 25min, then tempering is carried out in the tempering furnace, the tempering temperature is 650°C, and the heating rate is 2.5min / mm, The holding time is 60 minutes, and the comprehensive mechanical properties of the steel plate are shown in Table 2.

Embodiment 2

[0012] Embodiment 2: the quenching temperature of the rolled steel plate is 840 degrees, the heating rate is 1.7min / mm, and the holding time is 30min, then tempering is carried out in the tempering furnace, the tempering temperature is 580°C, and the heating rate is 2.7min / mm, The holding time is 40min, and the comprehensive mechanical properties of the steel plate are shown in Table 2.

Embodiment 3

[0013] Embodiment 3: the quenching temperature of the rolled steel plate is 820 degrees, the heating rate is 1.8min / mm, and the holding time is 20min, then tempering is carried out in the tempering furnace, the tempering temperature is 650°C, and the heating rate is 2.5min / mm, The holding time is 40min, and the comprehensive mechanical properties of the steel plate are shown in Table 2. Among them, the impact energy (J) of -80 degree 5% strain aging is the average value.

[0014] Table 2 steel plate performance result after the process of the present invention

[0015]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com