Press plunger device on tunnel type washing machine

A washing machine and tunnel-type technology, applied in washing devices, other washing machines, textiles and papermaking, etc., can solve the problems of wear of the upper part of the water bag, affecting the washing effect, and low life of the water bag, preventing rubber wear and good washing effect. , the effect of large water pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with specific embodiments.

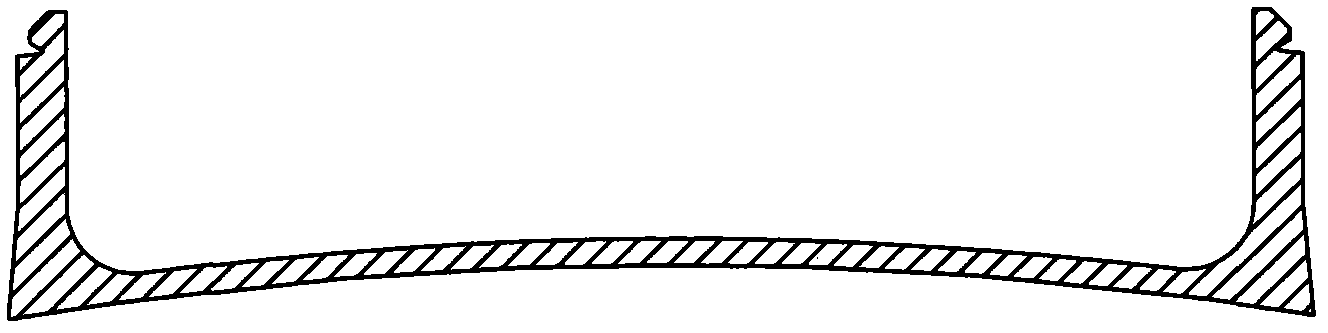

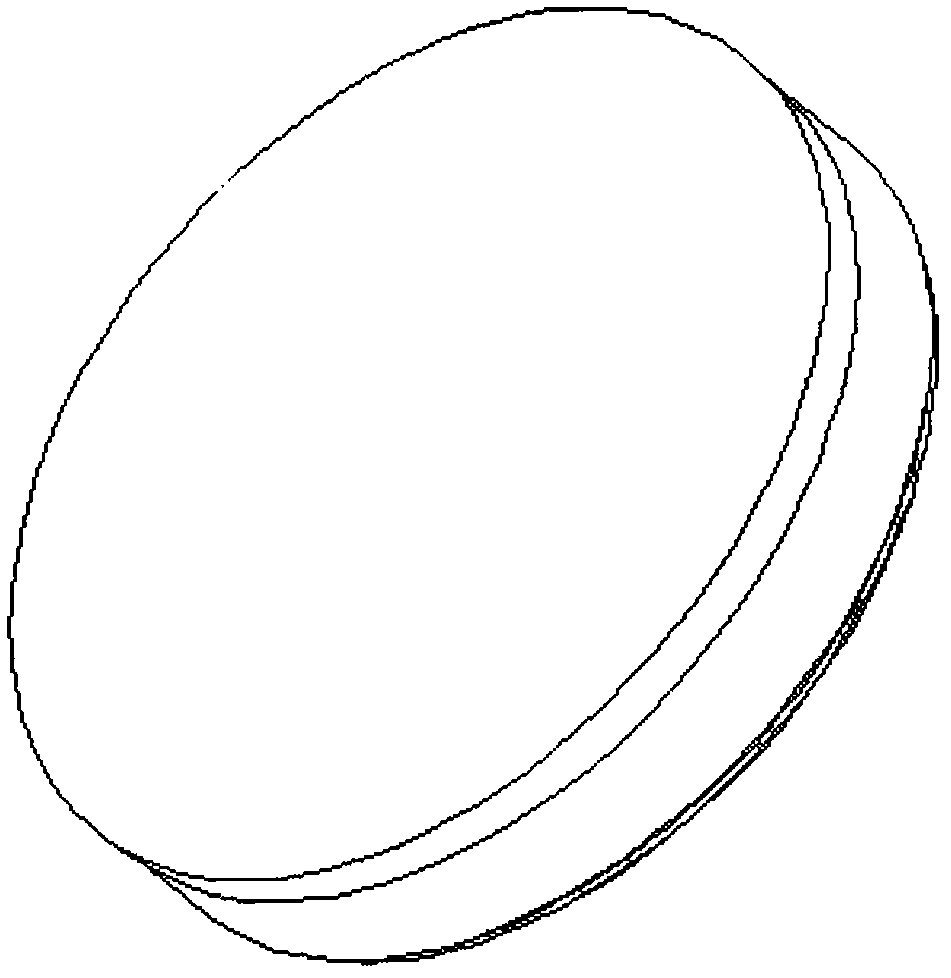

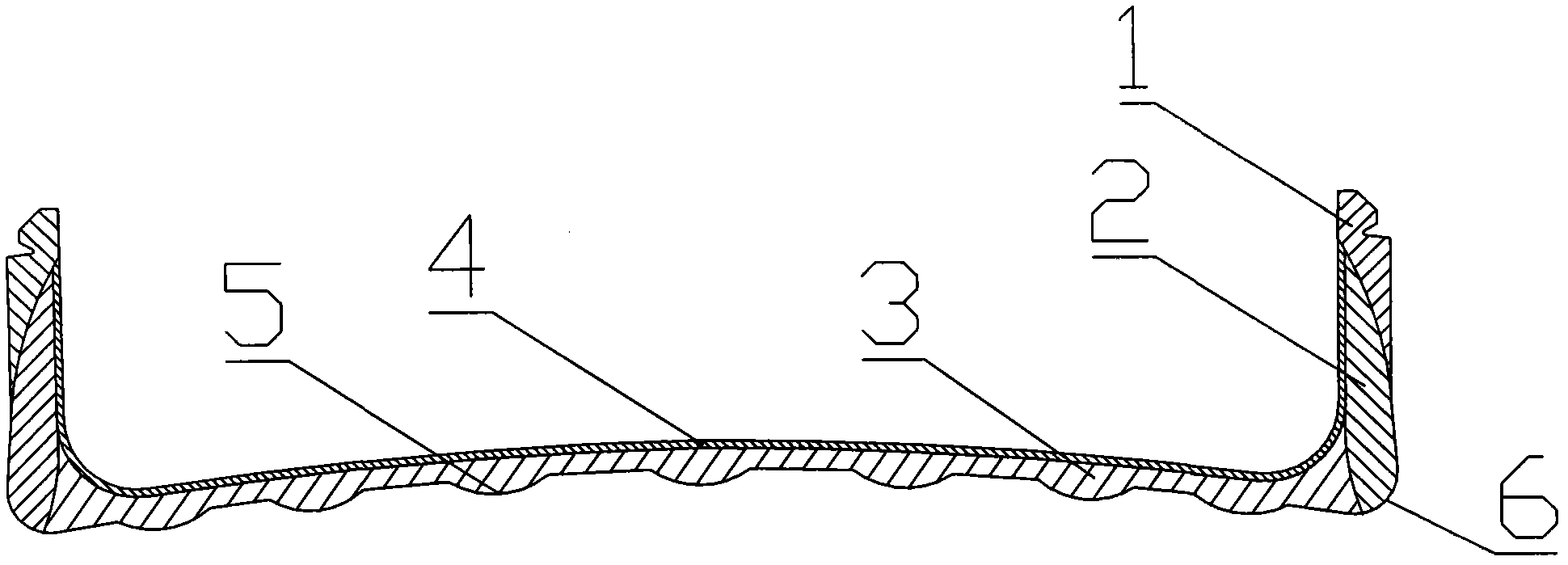

[0014] Such as image 3 As shown, the press plunger device on the tunnel washing machine includes a bottom part and a side part. The bottom part is formed by bonding the base glue 3 and the inner lining layer 4, the base glue 3 is the working surface, and the outer surface of the base glue 3 is distributed with at least one The spherical rubber block 5 with a radius of 15~80mm and a height of 4~12mm. The center of the spherical rubber block 5 is on the normal line of the outer surface of the base rubber; the side is composed of wear-resistant rubber 1, side rubber 2, and inner lining layer 4 is bonded together, the wear-resistant glue 1 and the side glue 2 are bonded by an arc-shaped long inclined surface, the side glue 2 and the base glue 3 are bonded by an arc surface, the inner lining 4 and the side The glue 2 is bonded by a plane. The side glue 2 is located between the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com