Construction process of large equipment hoisting tail sliding rail capable of reducing friction coefficient

A large-scale equipment and construction technology technology, applied in the direction of tracks, roads, ballast layers, etc., can solve the problems of main crane impact and increased safety risk of hoisting construction operations, so as to reduce traction force, avoid investment in large traction equipment, The effect of saving material consumption and construction workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

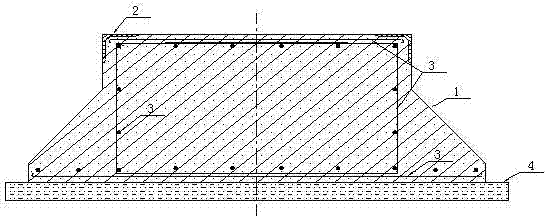

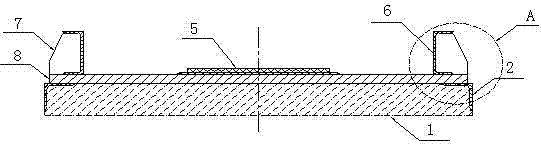

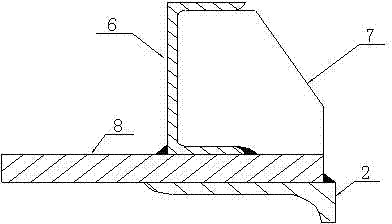

[0032] The sliding track of the hoisting tail row is composed of concrete cap 1, embedded angle steel 2, steel mesh 3, concrete cushion 4, PTFE slide plate 5, channel steel 6, rib plate 7, and track support bottom plate 8. After leveling the bottom surface, lay the concrete cushion 4, set the reinforcement mesh 3 above the concrete cushion 4, fix the pre-embedded angle steel 2 on the reinforcement mesh 3, and then cast the concrete cap 1; lay the track support base above the concrete cap 1 8. The two sides of the track support base plate 8 are welded together with the embedded angle steel 2 and fixed on the concrete cap 1; the channel steel 6 is welded with the track support base plate 8 as a whole, and at the same time, a reinforcement is welded on the outside of the channel steel 6 at intervals of 500 mm The rib plate 7; the PTFE slide plate 5 is laid along the center line of the sliding track, and the PTFE slide plate 5 is fixed with the track support base plate 8 by spot we...

Embodiment 2

[0035] In the hoisting of a 1,759-ton hydrogenation reactor at a certain construction site, the sliding weight was 870 tons. Using the technical solution described in the present invention, the measured friction force was 69.6 tons, and the measured friction coefficient was 0.08. Compared with the traditional "steel rollers rolling on the wooden track" and "the hoisting tail row sliding on the lubricated steel track", the friction coefficient is reduced by 50% and 33% respectively, and the original traction equipment can still meet the requirements required, which reduces the engineering cost; the sliding track designed according to the reduced friction coefficient saves the amount of materials and construction work, and reduces the engineering cost; more importantly, due to the significantly reduced friction, the hoisting tail on the track Sliding is continuous and stable, avoiding the traditional discontinuous (pulse) movement mode, and the traction force will be transmitted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com