Integrated single-cylinder engine base structure

A single-cylinder engine, integrated technology, applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the complex mechanism status inspection and replacement process, the large ratio of horizontal and vertical dimensions of the machine base structure, and the impact of the machine base partition To solve problems such as large loads, achieve the effects of convenient installation and status inspection, improvement of working intensity, and guaranteed performance of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] specific implementation

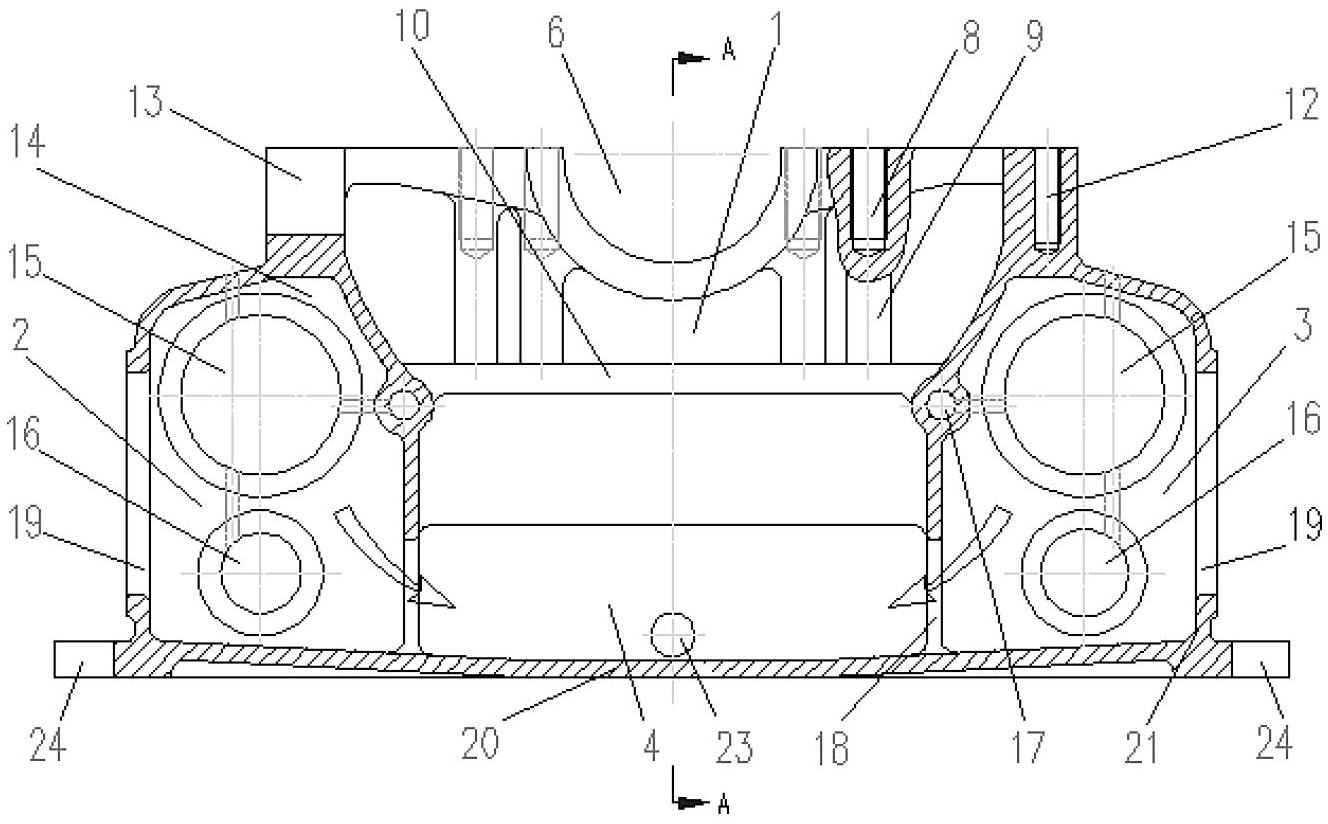

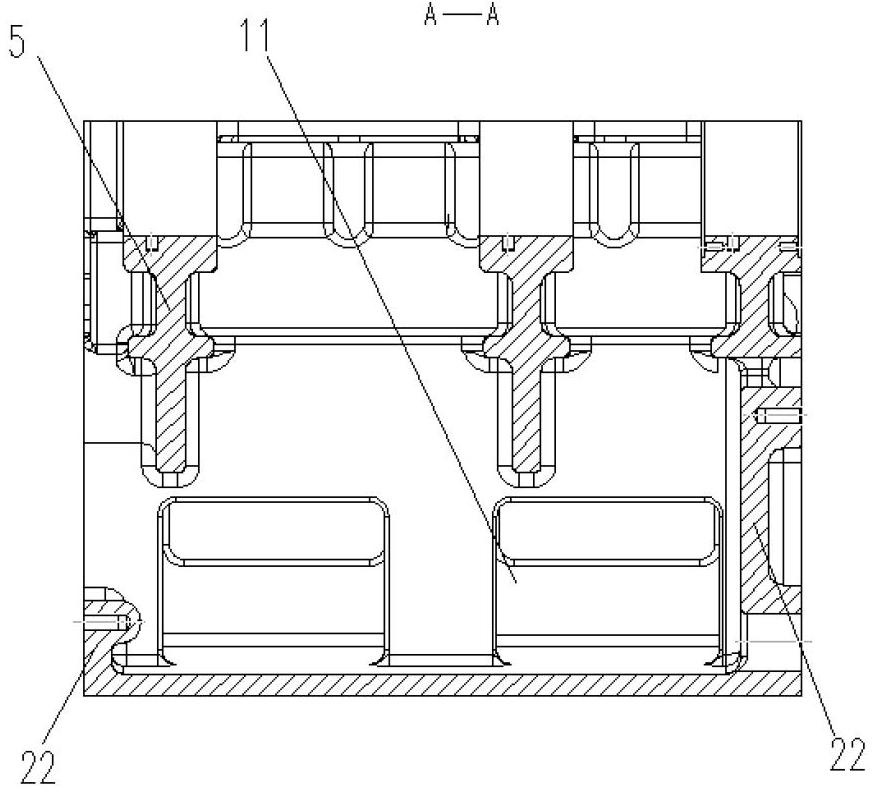

[0015] An integrated single-cylinder machine base structure, which includes a lower crankcase 1, a left balance chamber 2, a right balance chamber 3 and an oil pan 4, and the left and right balance chambers 2 and right The balance chamber 3 and the oil pan 4 are arranged at the bottom of the left balance chamber 2 and the right balance chamber 3 .

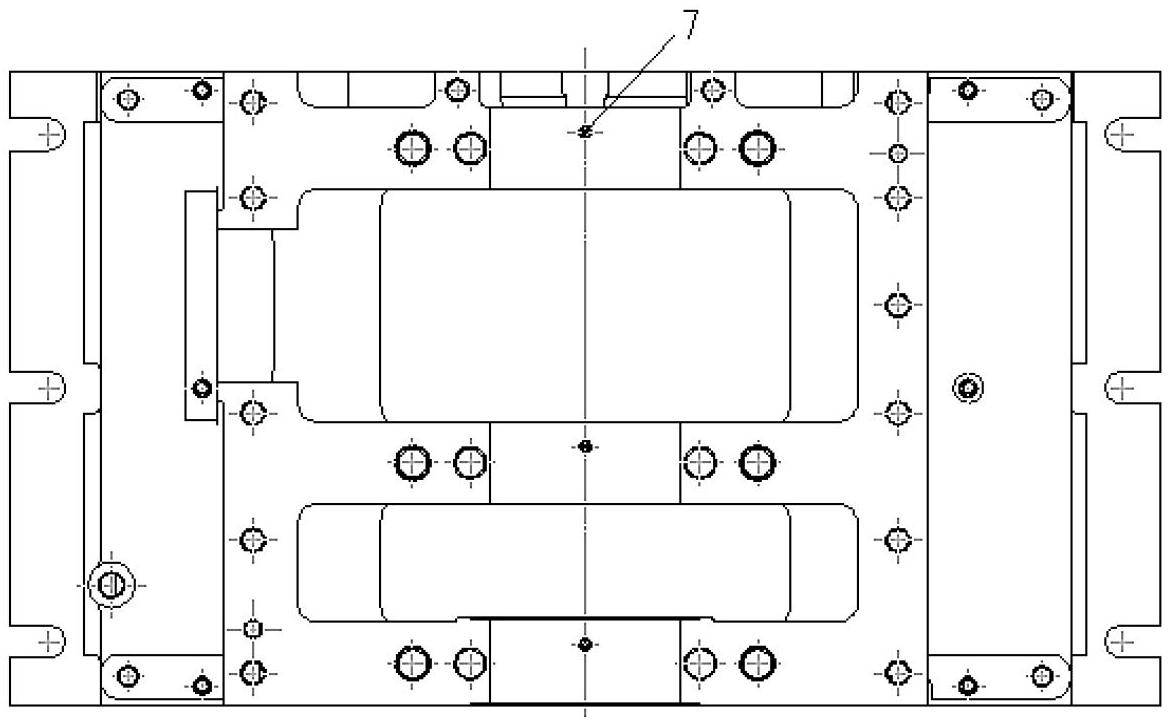

[0016] The left and right side walls of the lower crankcase 1 are respectively provided with connecting bolt holes 12, the U-shaped connecting rod dismantling window 13 is arranged on the right side wall of the lower crankcase 1, and the lower crankcase 1 is longitudinally provided with first crankshaft supports in sequence. The partition 5, the second crankshaft supports the partition 5, the third crank supports the partition 5, the first crank supports the partition 5, the second crank supports the partition 5, and the third crank supports the partition 5 with first transverse Rib 10, the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com