Spent fuel water tank natural ventilation and water recovery system responding to serious accident

A spent fuel pool and natural ventilation technology, applied in ventilation systems, space heating and ventilation, applications, etc., can solve problems such as hydrogen explosions, hydrogen accumulation in fuel plants, radiation pollution, etc., to prevent overheating, prolong submersion time, non-toxic The effect of active characteristics and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

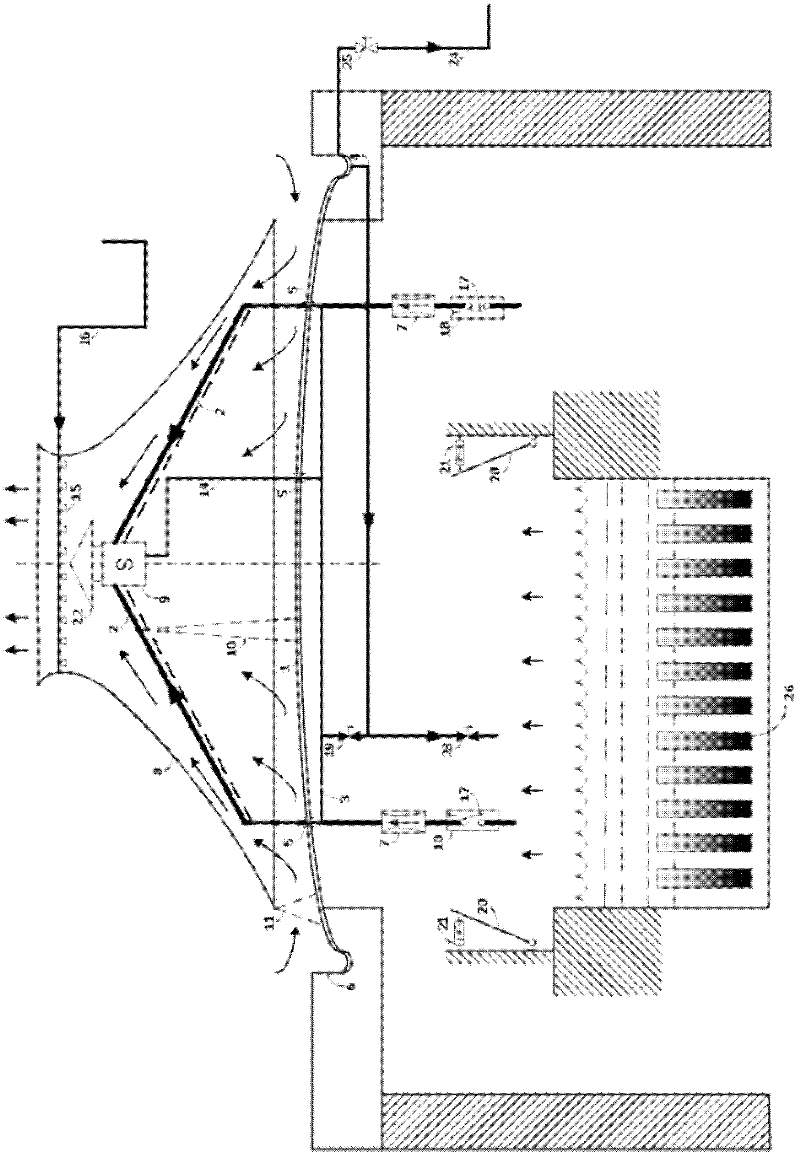

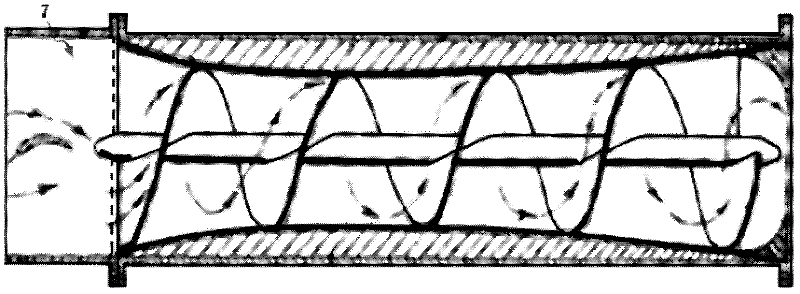

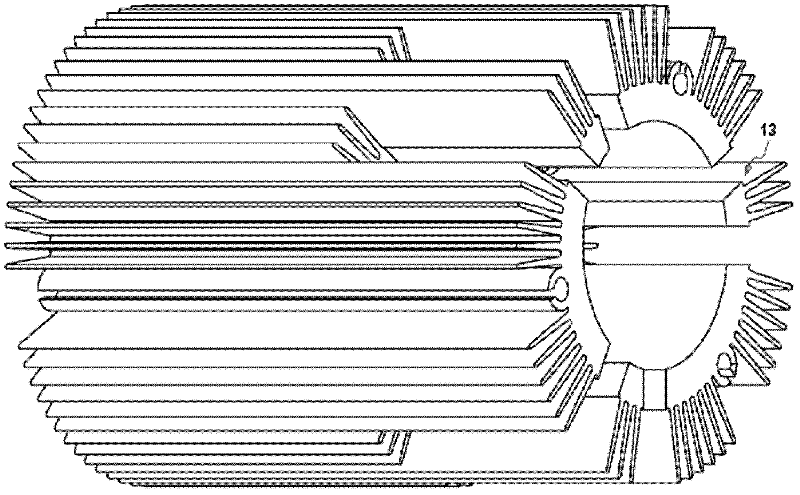

[0022] Such as figure 1 As shown, the natural ventilation and water recovery system of the spent fuel pool for severe accidents includes a metal dome 1 as a part of the roof of the fuel plant. The metal dome 1 has a plurality of ventilation channels 2 for natural ventilation of the spent fuel pool in severe accidents. A natural ventilation chimney 8 is arranged above the whole of the plurality of ventilation channels 2. The entrance of the ventilation channel 2 is located above the spent fuel pool where the spent fuel assembly 26 is stored, and the outlet of the ventilation channel 2 is connected to the water eliminator 9. An atomizing sprinkler 15 is provided between the outlet of the water eliminator 9 and the exhaust port of the water eliminator 9. The atomizing sprinkler 15 is connected to the spray water supply pipeline 16 arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com