Ultra-low-temperature pulse-tube refrigerator, method for operating pulse-tube refrigerator, and rotary valve

A pulse tube and refrigerator technology, applied in refrigerators, multi-way valves, valve devices, etc., can solve the problems of large drive valve torque, large valve disc force, etc., and achieve the effect of reducing the drive torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

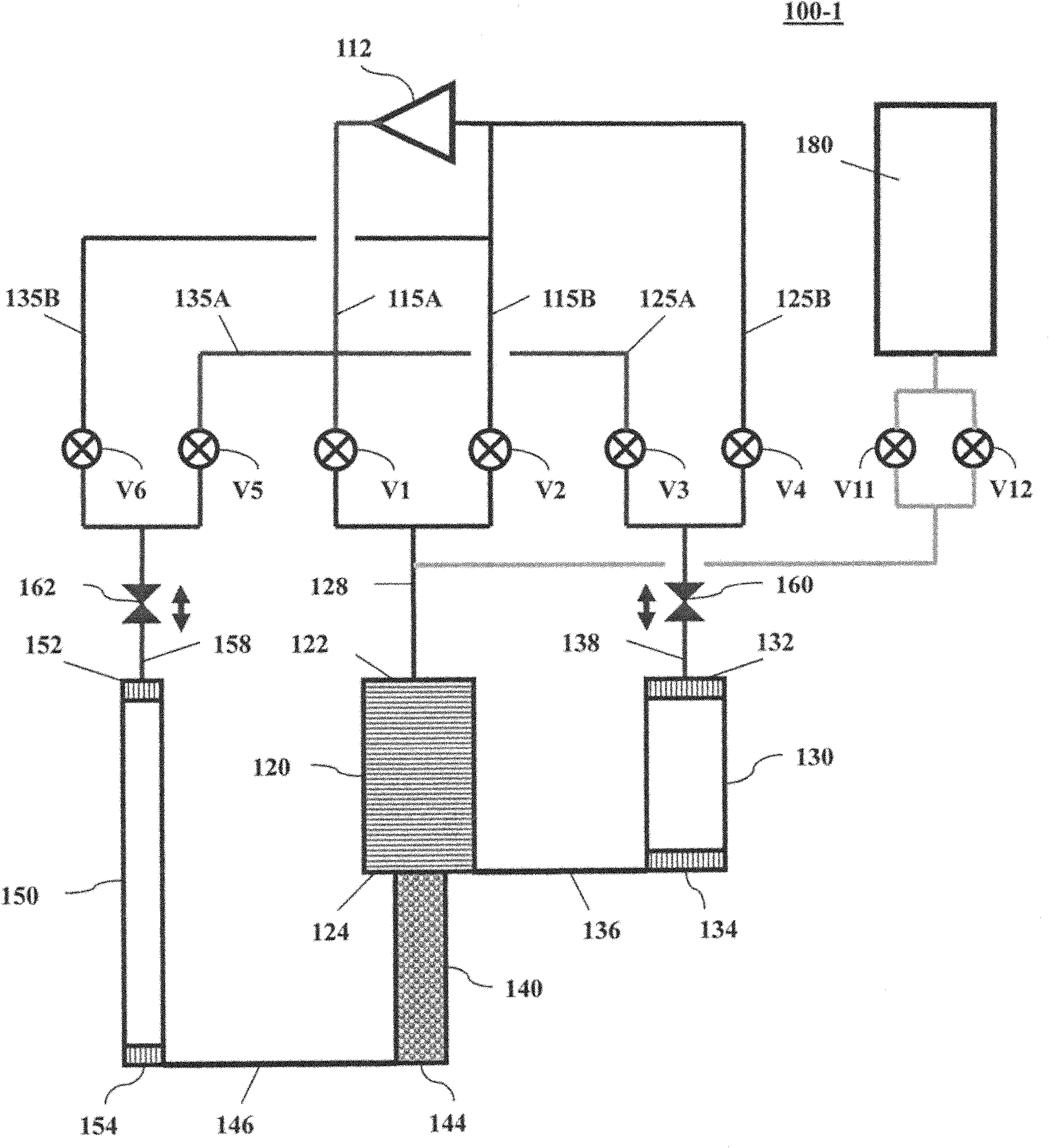

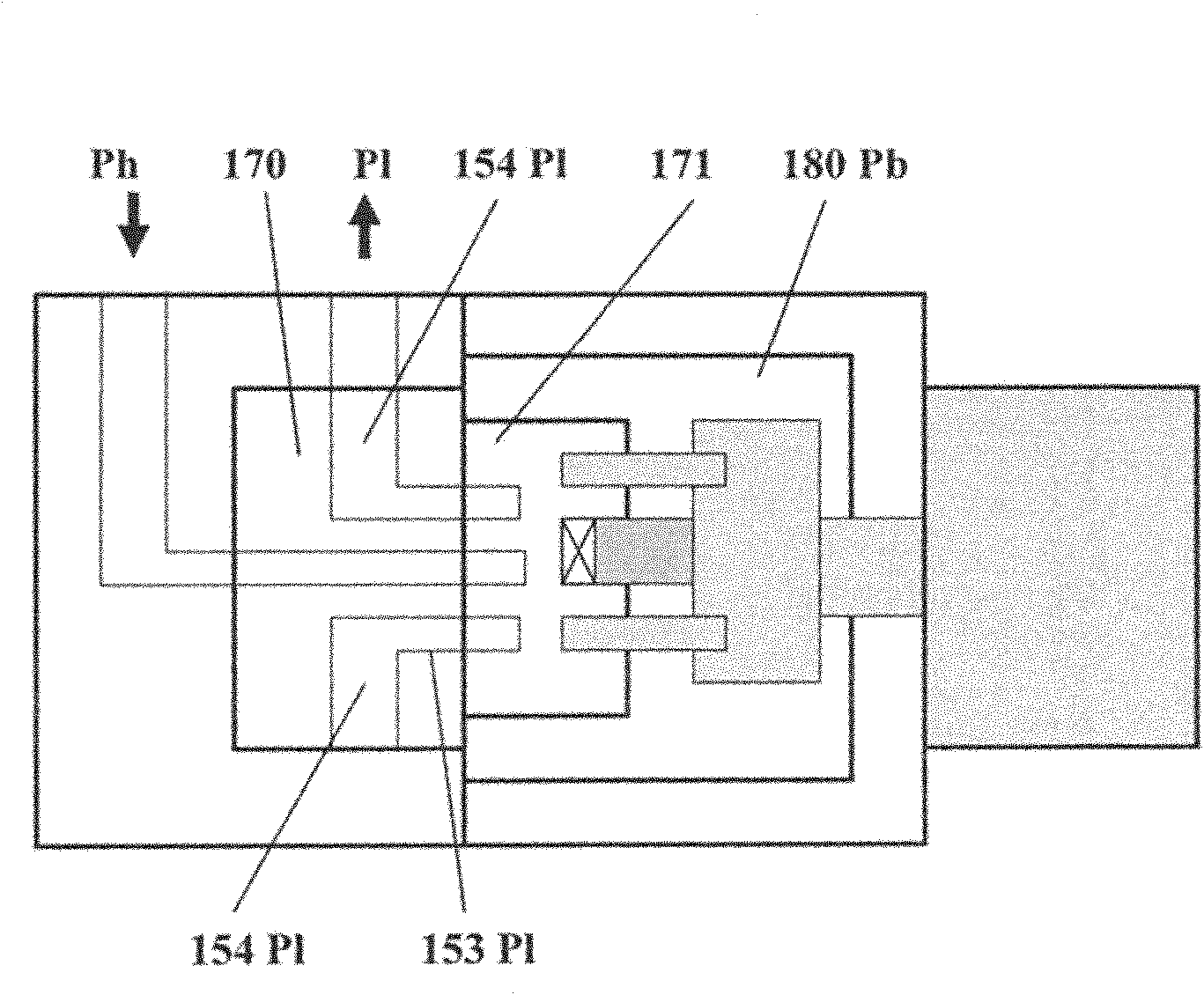

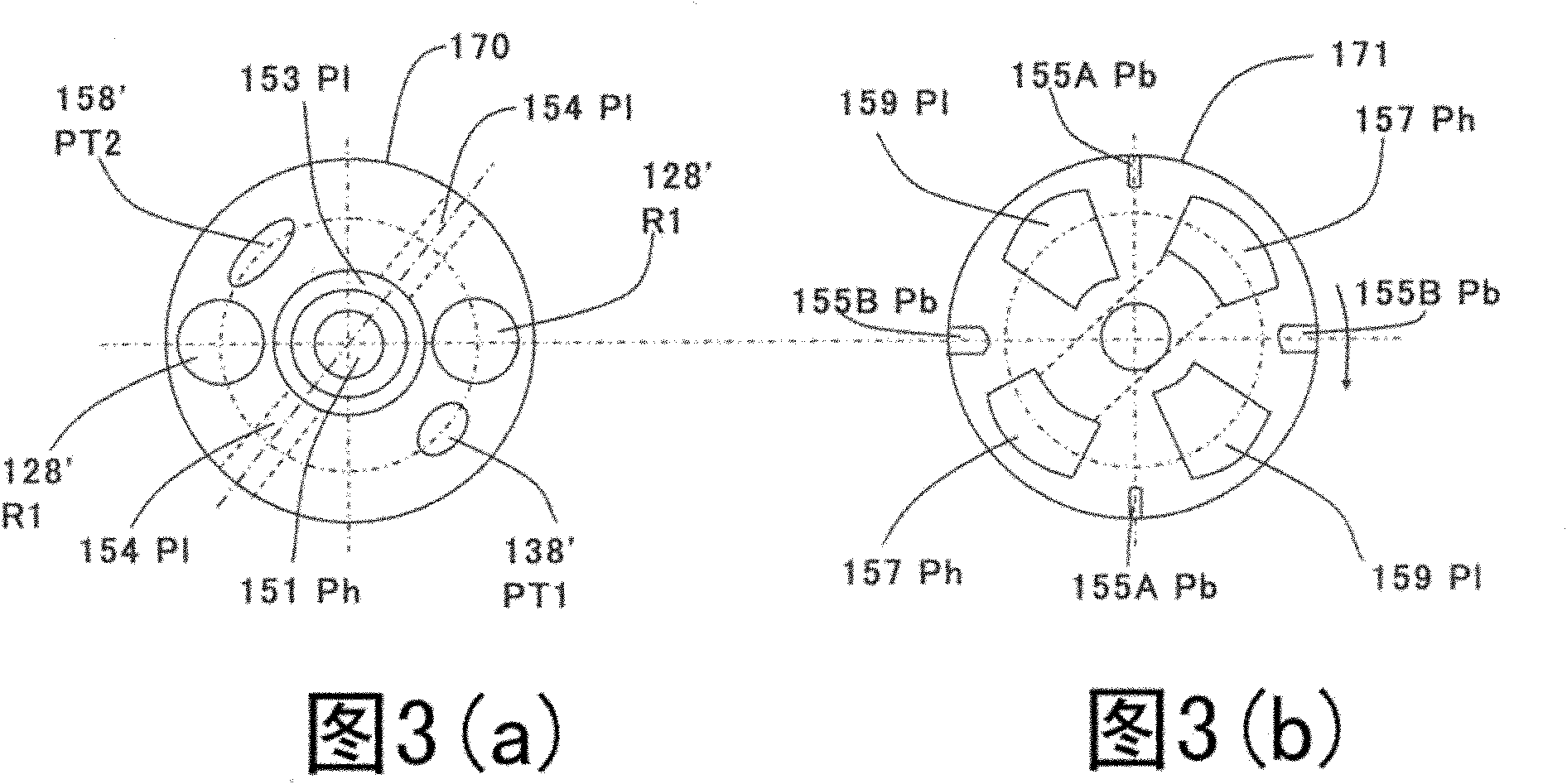

[0048] figure 1 It is a diagram showing the structure of a two-stage four-valve pulse tube refrigerator according to the first embodiment of the present invention. The high-pressure gas Ph flows from the compressor 112 through the first high-pressure piping 115A, the second high-pressure piping 125A, and the third high-pressure piping 135A into the valves V1 , V3 , and V5 . The low-pressure gas P1 returns to the compressor 112 from the valves V2, V4, and V6 through the first low-pressure piping 115B, the second low-pressure piping 125B, and the third low-pressure piping 135B, respectively. The valve V1 controls the airflow flowing into the first regenerator 120 ( R1 ) through the common piping 128 . The valve V2 controls the airflow flowing out from the first regenerator 120 ( R1 ) through the common piping 128 . The valve V3 controls the gas flow flowing into the first-stage pulse tube 130 (PT1) through the common pipe 138 and the first flow path resistance member 160 . Th...

no. 2 Embodiment

[0060] Figure 5 It is a configuration diagram showing a three-stage four-valve type pulse tube refrigerator 200-1 according to the second embodiment of the present invention. The high-pressure gas Ph flows from the compressor 212 through the high-pressure pipes 215A, 225A, 235A, and 245A into the valves V1 , V3 , V5 , and V7 . The low-pressure gas P1 returns to the compressor 212 from the valves V2, V4, V6, and V8 through the low-pressure piping 215B, 225B, 235B, and 245B. The valve V1 controls the airflow flowing into the first regenerator 220 ( R1 ) through the common piping 228 . The valve V2 controls the airflow flowing out from the first regenerator 220 ( R1 ) through the common piping 228 . The valve V3 controls the airflow flowing into the first-stage pulse tube 230 (PT1) through the common pipe 238 and the first flow path resistance member 260 . The valve V4 controls the airflow flowing out from the first-stage pulse tube 230 (PT1) through the common pipe 238 and t...

no. 3 Embodiment

[0068] Figure 8 It is a configuration diagram showing a single-stage four-valve pulse tube refrigerator 300-1 according to a third embodiment of the present invention. The high-pressure gas Ph flows from the compressor 312 through the high-pressure pipes 315A and 325A into the valves V1 and V3. The low-pressure gas P1 is returned to the compressor 312 from the valves V2 and V4 through the low-pressure piping 315B and 325B. The valve V1 controls the airflow flowing into the first regenerator 320 ( R1 ) through the common piping 328 . The valve V2 controls the airflow flowing out from the first regenerator 320 ( R1 ) through the common piping 328 . The valve V3 controls the air flow flowing into the first-stage pulse tube 330 (PT1) through the common pipe 338 and the first flow path resistance member 360 . The valve V4 controls the airflow flowing out from the first-stage pulse tube 330 (PT1) through the common pipe 338 and the first flow path resistance member 360 . Valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com