RH-MFB (Rockwell Hardness-Medial Forebrain Bundle) metallurgy reaction simulation test device

A simulation test and reaction technology, applied in the field of metallurgy, can solve problems affecting the production rhythm of continuous casting, and achieve the effects of human-computer interaction, reliable use, and simple equipment mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

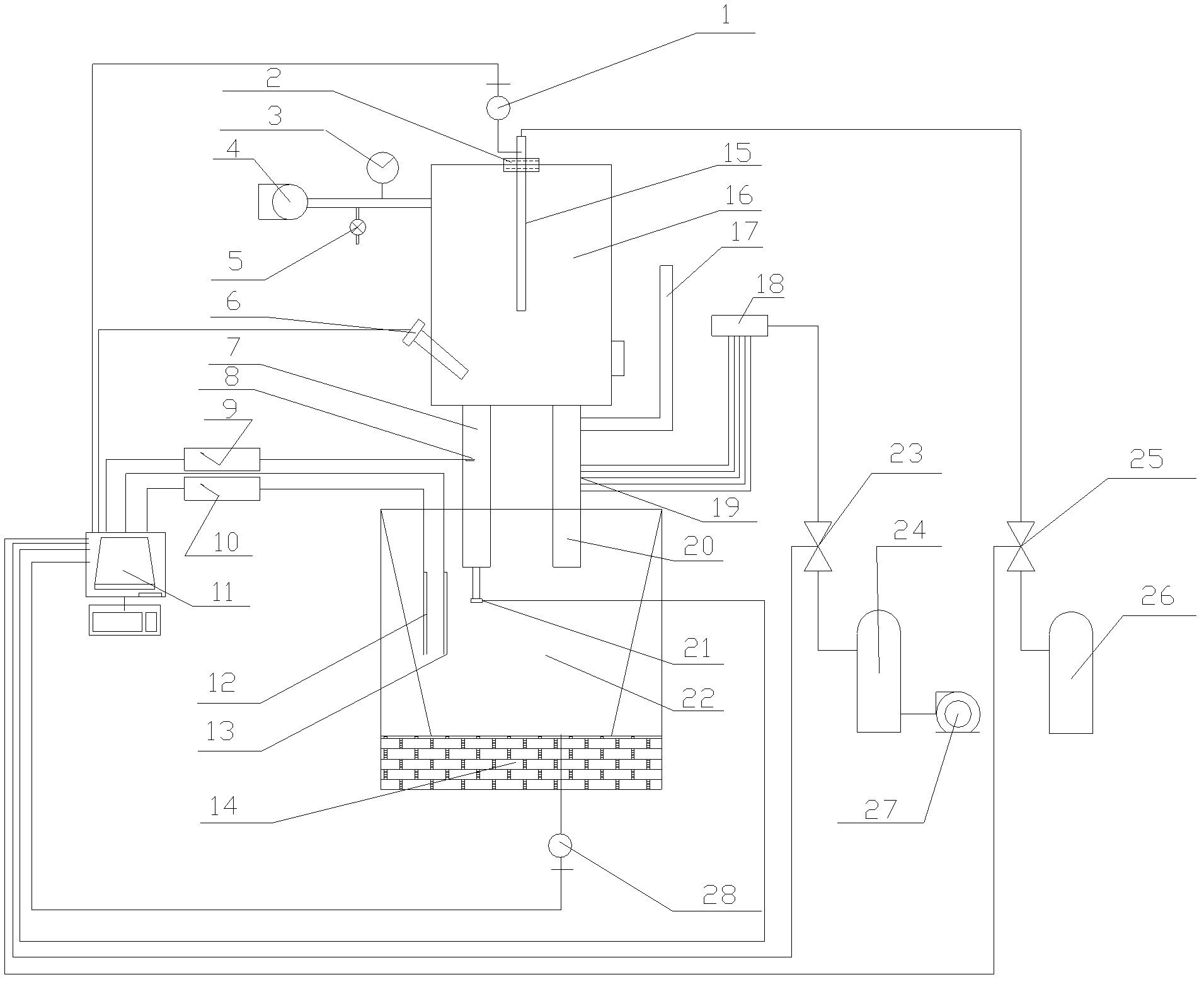

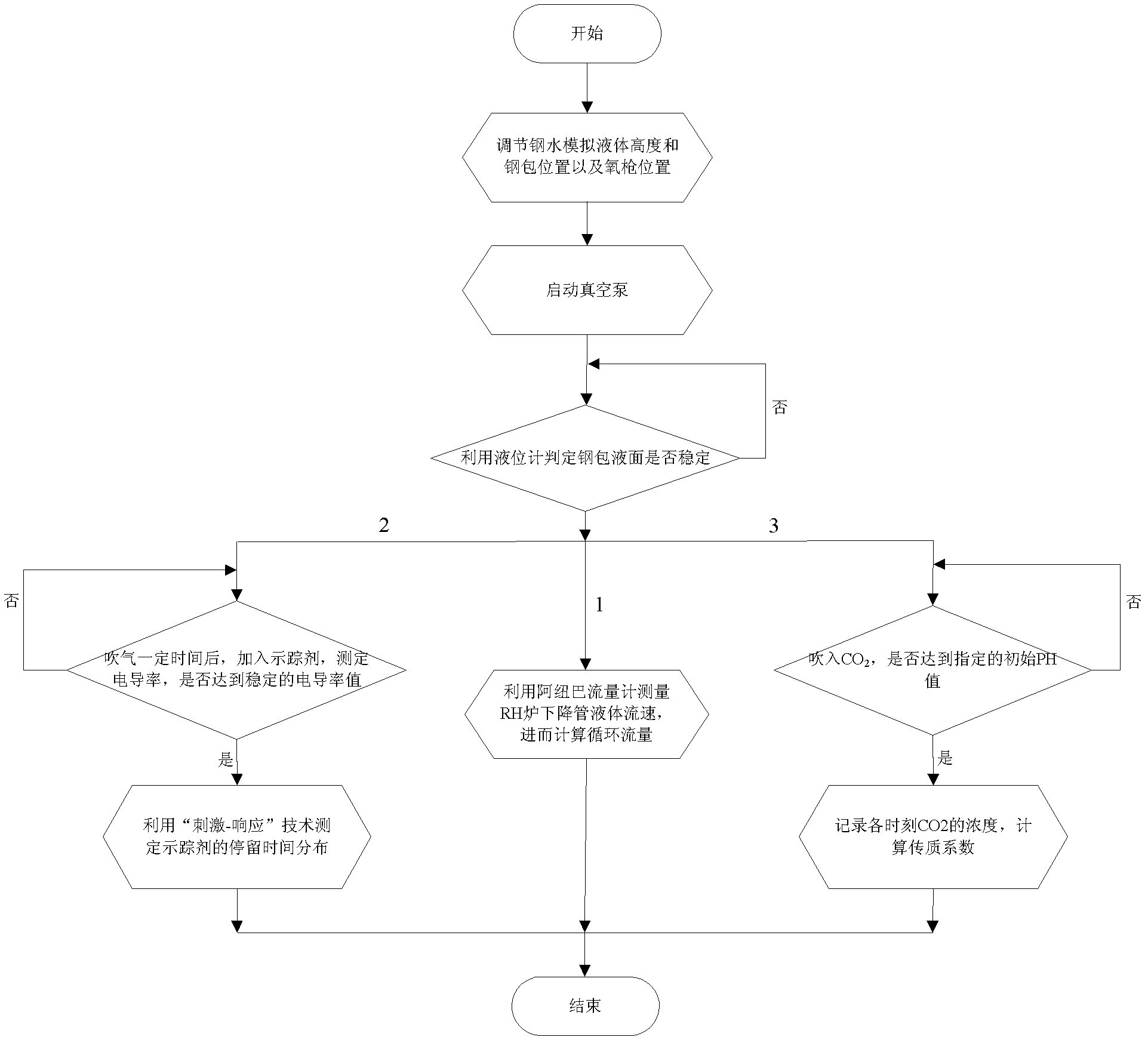

[0048] The RH-MFB metallurgical reaction simulation test device of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0049] The RH-MFB metallurgical reaction simulation test device of the present invention has a structure such as figure 1 As shown, it includes RH furnace vacuum chamber 16, ladle 22, control electric cabinet 11 and gas supply device.

[0050] The vacuum chamber 16 of the RH furnace is a pressure vessel made of plexiglass, and the size of the model can be adjusted according to the test requirements. The model of this embodiment is made in a ratio of 1:5.45 to the actual vacuum chamber of the RH furnace. The upper part of the RH furnace vacuum chamber 16 is connected with an oxygen lance 15. The oxygen lance 15 adopts a single-hole Laval nozzle. The material of the nozzle head is plexiglass, and the material of the gun body is seamless steel pipe. Ring 2 is used for sealing. In this example, an inflatable se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com