Rotary sealing bottom type superficial layer in-situ sediment sampler

A mud sampler and shallow layer technology, which is applied in the field of rotary bottom-covered shallow in-situ mud sampler, can solve the problems of shallow mud sample disturbance and easy mud leakage, and achieve small mud sample disturbance, convenient portability, and high sampling efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical solutions, technical features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific embodiments and accompanying drawings.

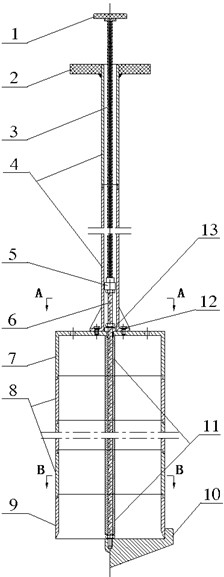

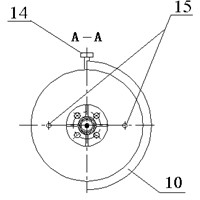

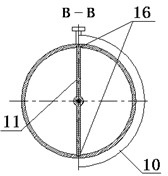

[0027] figure 1 It is a half-section front view of the dredger of the present invention, illustrating the internal structure of the dredger, a rotary bottom-sealed shallow in-situ dredger, including a sampling cylinder, and is characterized in that: it also includes a connection with the top of the sampling cylinder And the casing 4 located outside the sampling cylinder, the semi-conical bottom seal 10 covering the bottom of the sampling cylinder, the separator 11 located inside the sampling cylinder, the rotating shaft 6 connected to the semi-conical bottom seal 10 at the bottom, and the connecting rotating shaft 6 The soft spring 3 at the top; the rotating shaft 6 is located in the sampling cylinder and the casing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com