Torsional rigidity adjusting device

A technology of adjusting device and torsional stiffness, applied in the direction of measuring device, strength characteristics, instruments, etc., can solve the problems of low design and test efficiency, cumbersome process, long cycle, etc., to improve design and test efficiency, simplify operation process, process handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

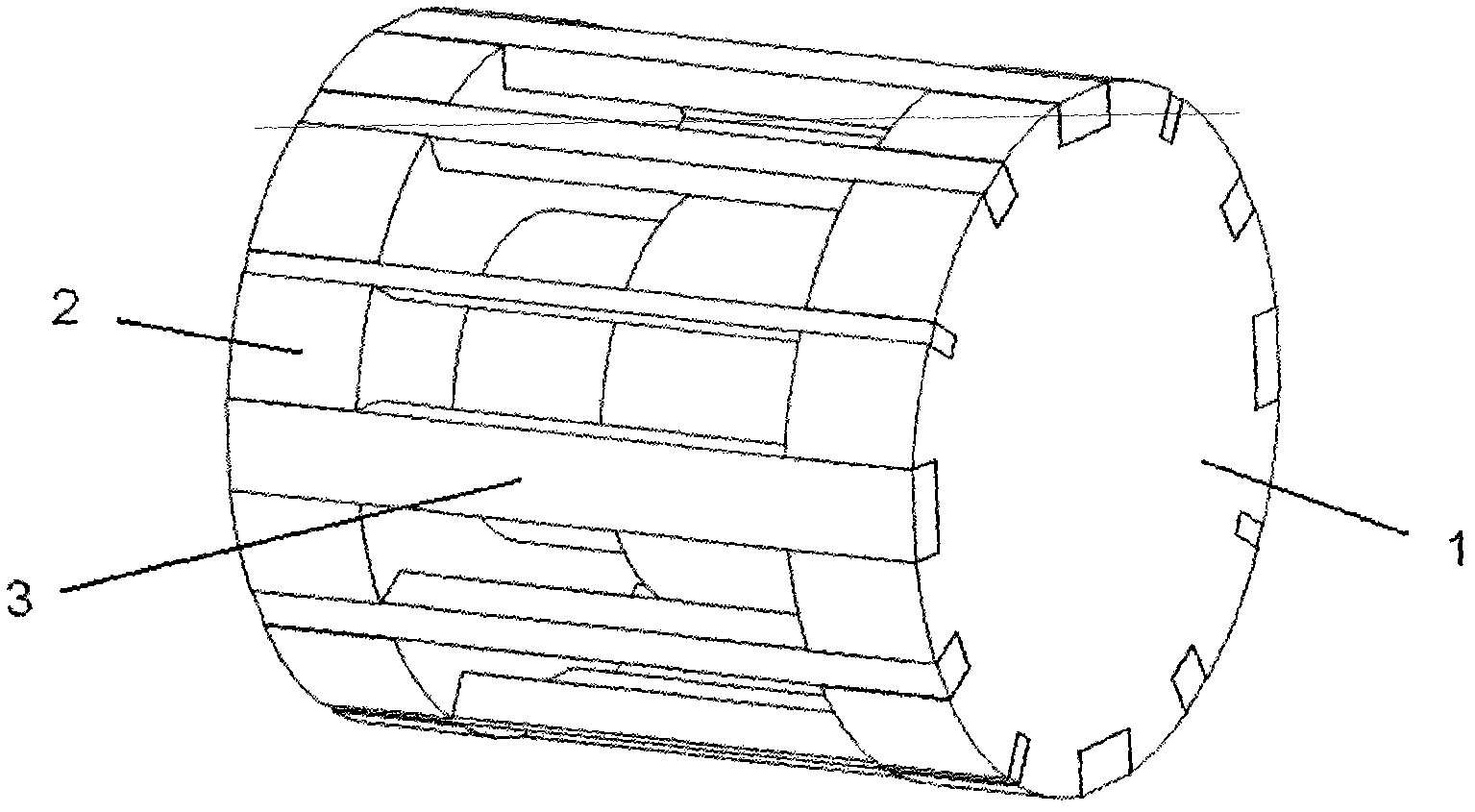

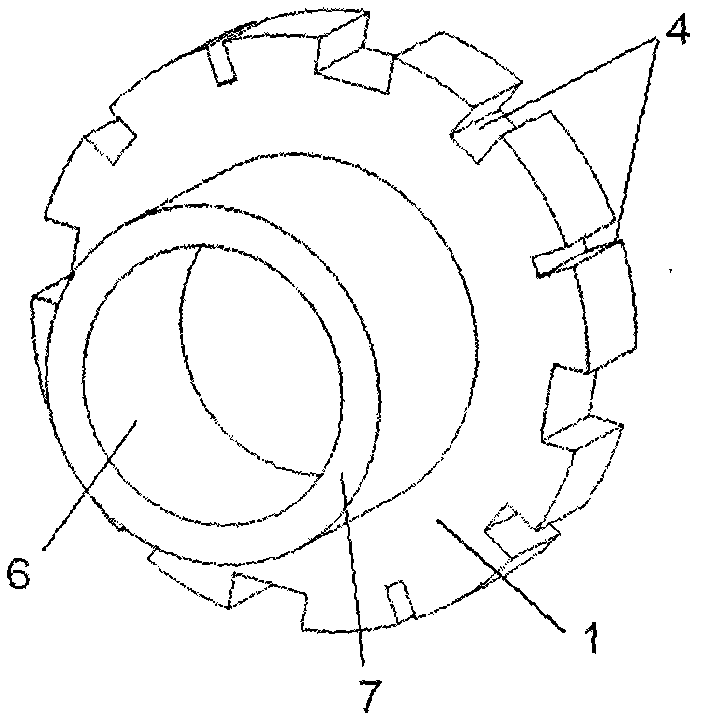

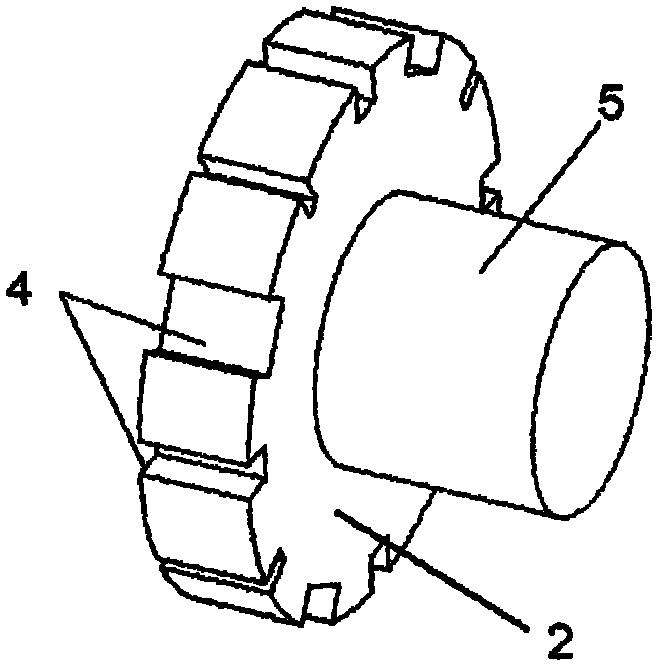

[0015] This embodiment is a torsional stiffness adjustment device, which includes a sub-end plate 2 , a female end plate 1 and multiple sets of flexible rods 3 . The sub-end plate 2 is in the shape of a truncated cone, with a circular boss 5 processed in the middle and a card slot 4 processed in the axial direction around it. The female end plate 1 is also in the shape of a circular frustum, and there are card slots 4 processed around it corresponding to the sub-end plate 2. The size and number of the card slots 4 are the same as those of the sub-end plate 2. There is an annular boss 7 processed in the middle, and the middle part of the annular boss 7 is processed. Circular groove6.

[0016] The number of flexible rods 3 is the same as the draw-in groove 4 on the same child and female end plates in cross-sectional shape.

[0017] When in use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com