Bubbling experiment device for mechanical-electric-magnetic coupling behavior of electromagnetic intelligent material and test method

An experimental device and a bubbling device technology are applied in the field of bubbling experimental devices of electromagnetic intelligent material force-electromagnetic coupling behavior, which can solve the problems of test error, difficulty in meeting new electromagnetic material testing requirements, low film displacement testing accuracy, etc. Effects of Representation Function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

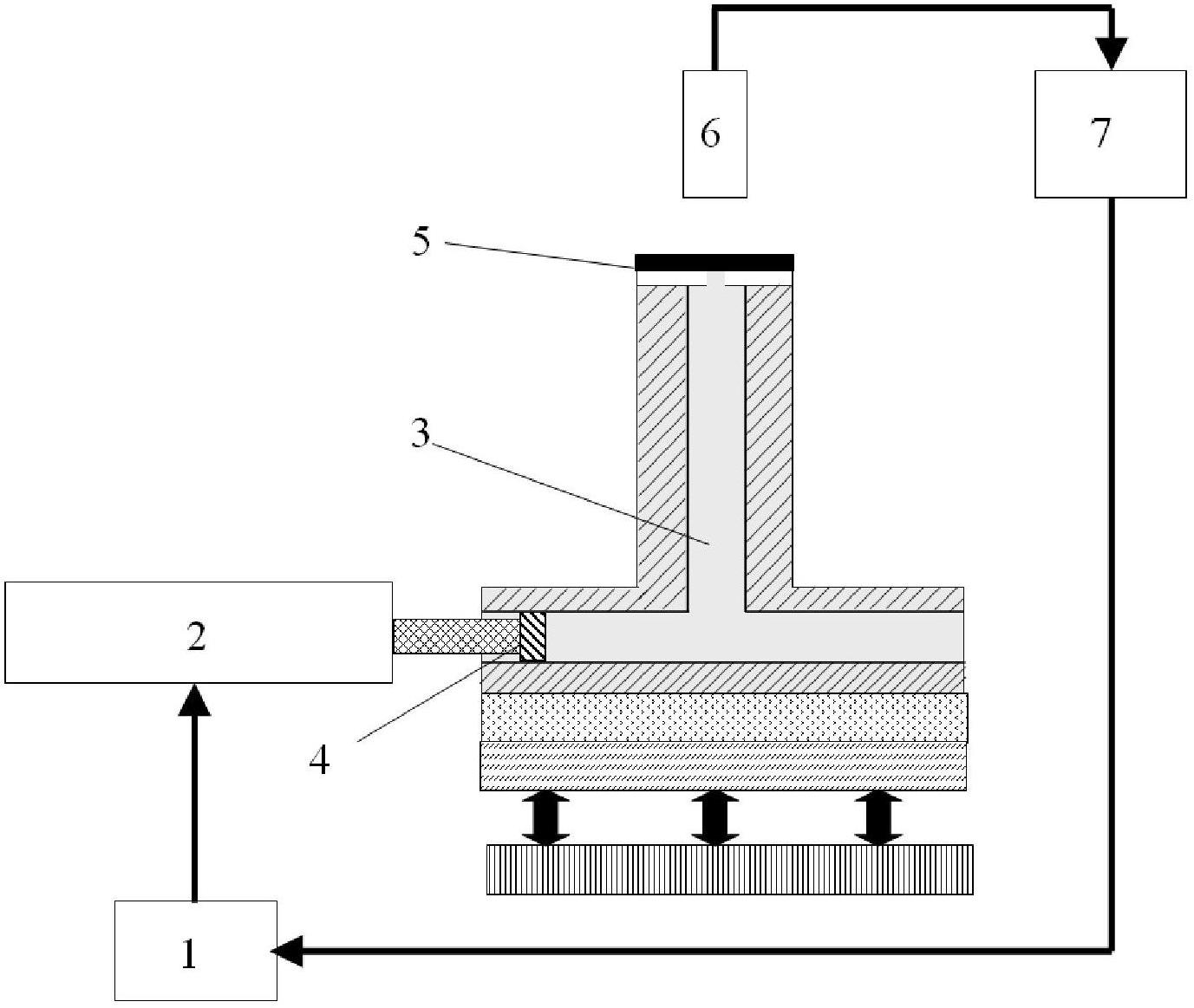

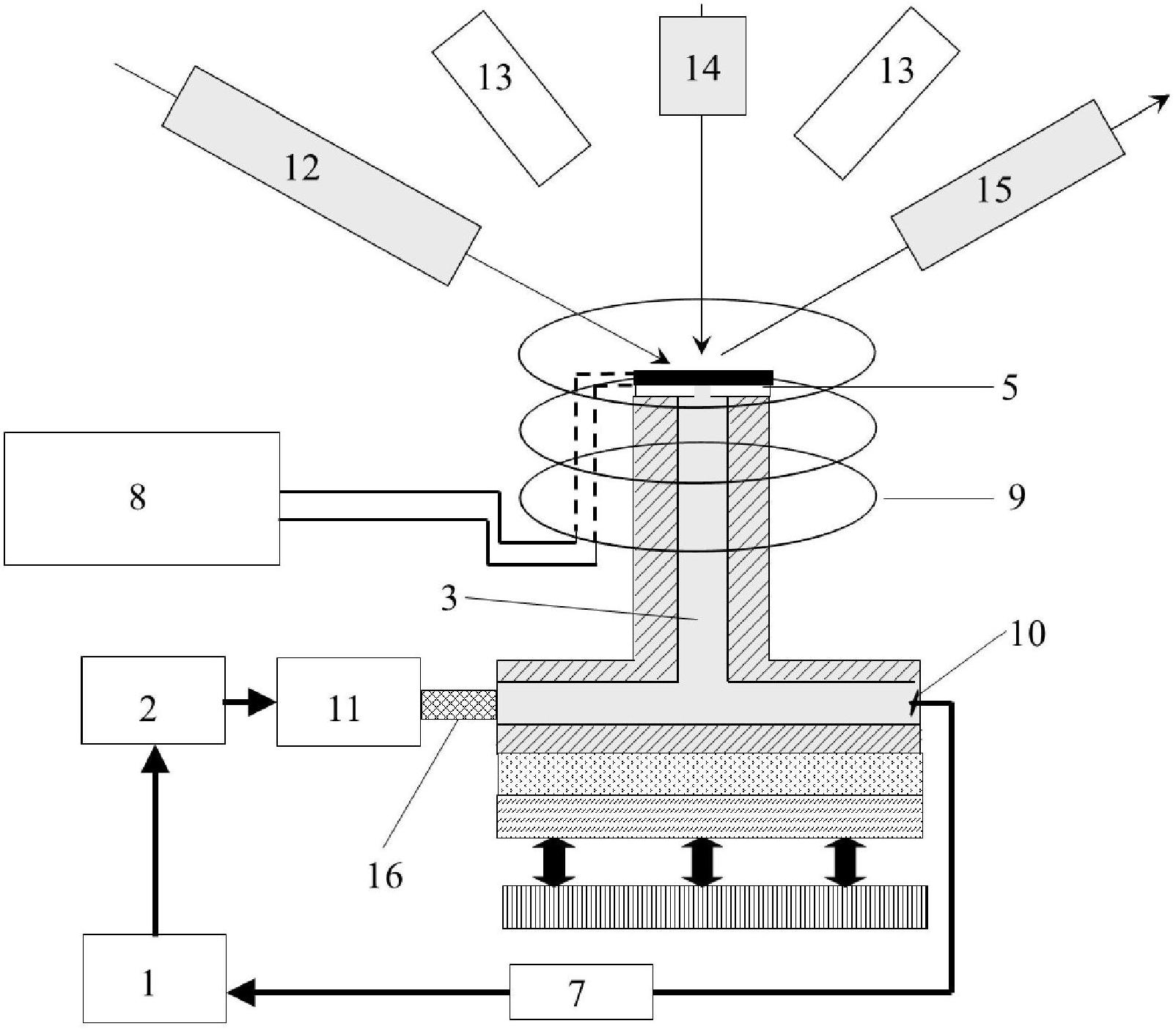

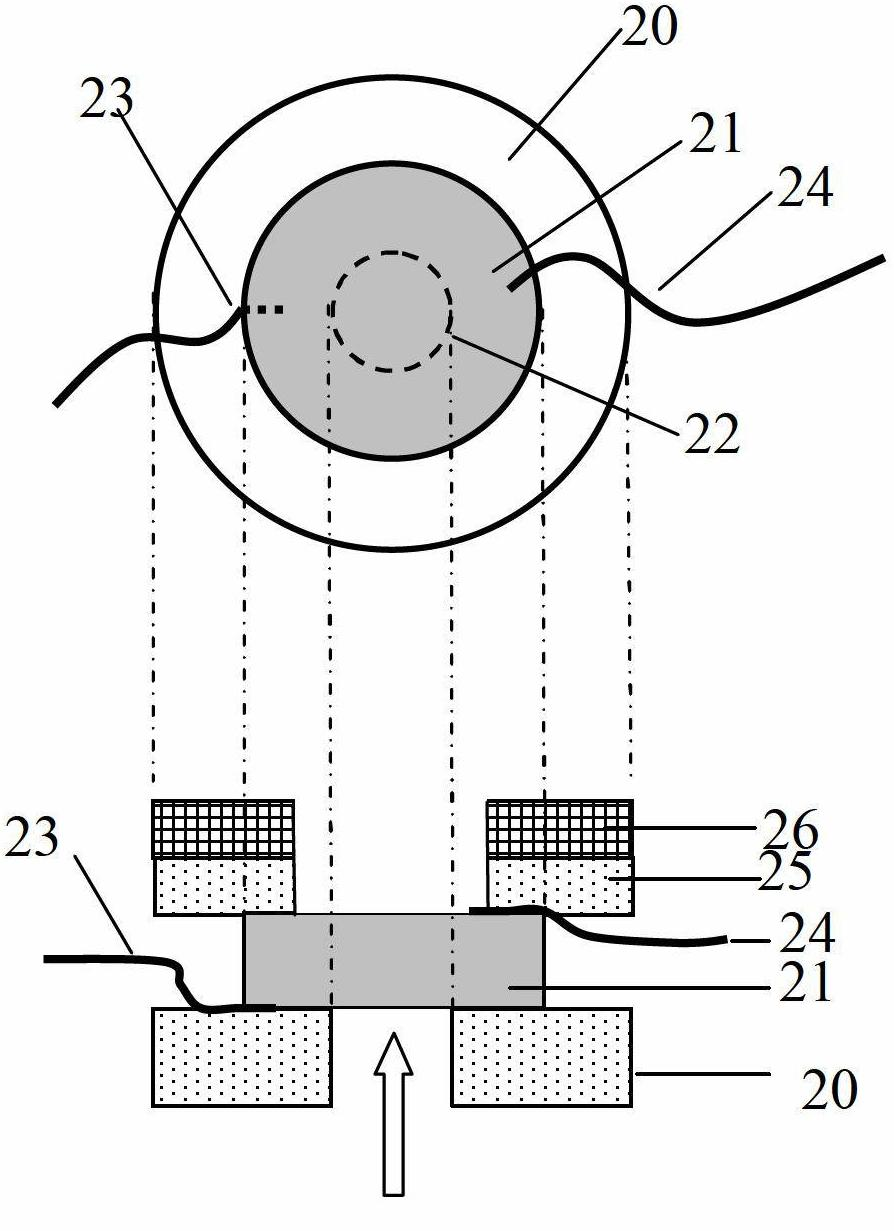

[0039] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0040] The constitutive relationship of the electromagnetic composite thin film sample is studied by the bubbling method under the coupling action of the force-electromagnetic three-field, and the general formula of the constitutive relationship can be expressed as:

[0041] ε ij =ε ij (σ ij ,H i ,E i ) (1)

[0042] B i =B i (σ ij , H i ,E i ) (2)

[0043] D. i =D i (σ ij , H i ,E i ) (3)

[0044] where σ ij is the stress, ε ij is the strain, B i is the magnetic induction intensity, H i is the magnetic field strength, D i is the electric displacement, and Ei is the electric field intensity. It can be seen from the constitutive equation that when the independent variables are stress, magnetic field strength and electric field strength, the dependent variables are strain, magnetic induction and ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com