Ceramic quad flat package (CQFP) series aging test socket with pitch being no less than 0.8mm

A technology for testing sockets and burn-in, which is applied in the direction of measuring electricity, measuring devices, and measuring electrical variables. It can solve problems such as low thermal deformation temperature, small positioning device, and socket failure, and achieve reliable contact, easy processing, and easy product assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

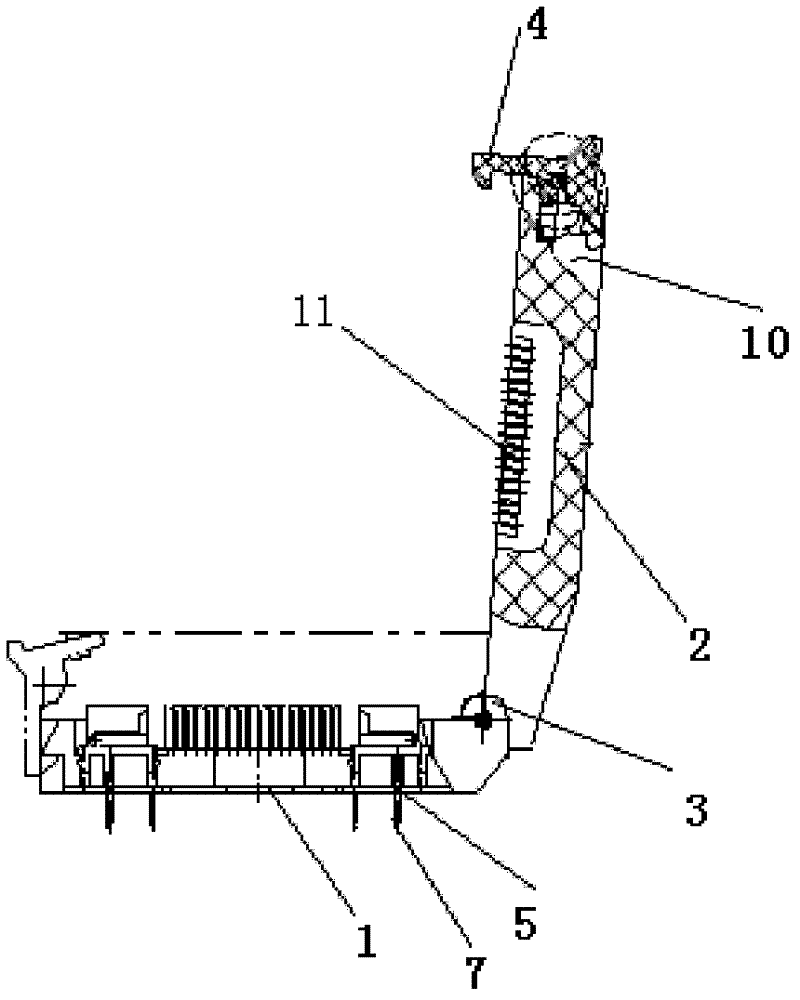

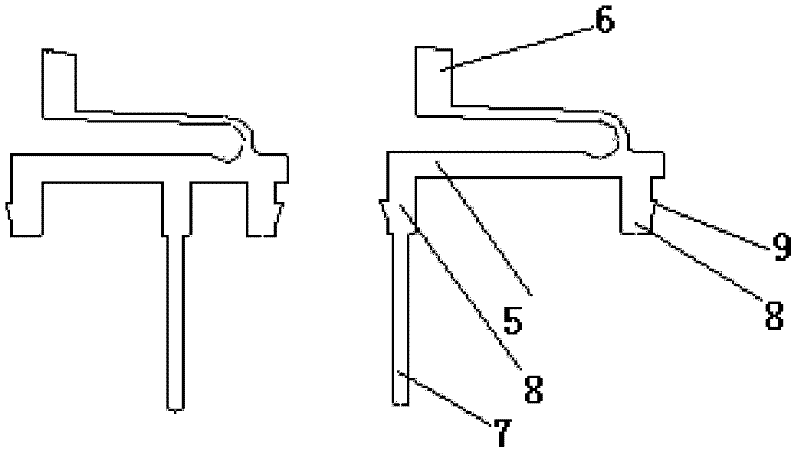

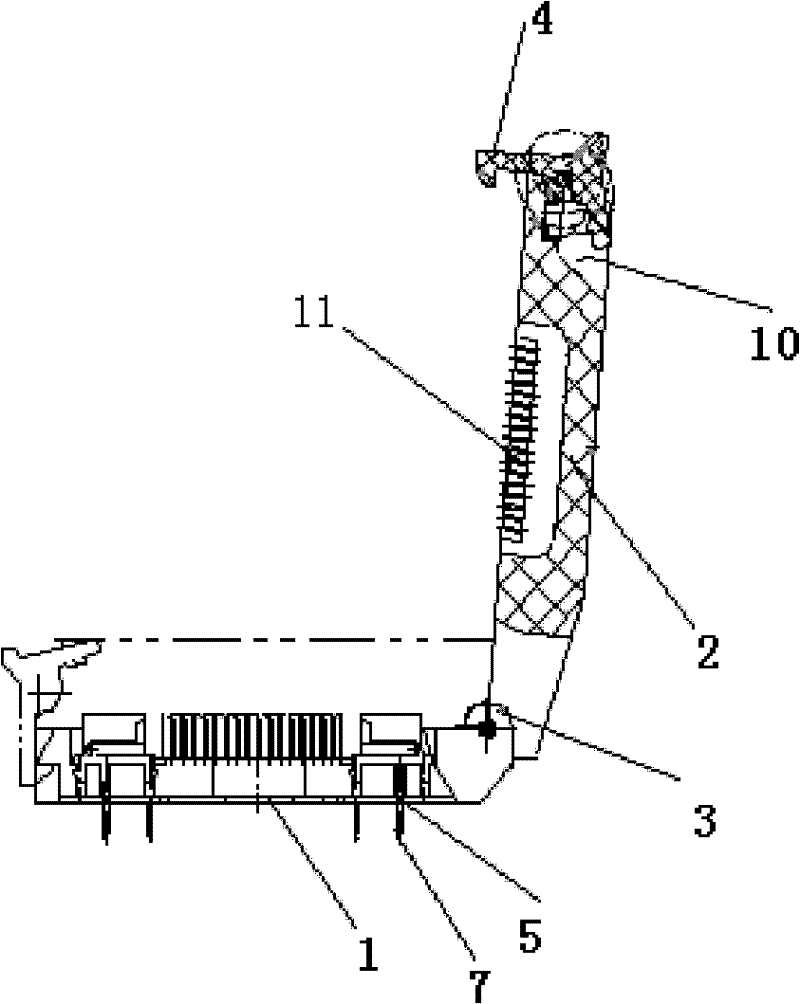

[0020] Referring to the attached figure, the CQFP series burn-in test socket with a pitch of not less than 0.8mm includes a mounting plate 1 and a cover plate 2 which are articulated through hinges. The width of the groove, but the teeth 11 larger than the width of the lead wire of the package, its function is to give sufficient pressure to the lead wire of the package through the contact piece; the upper and lower surfaces of the cover plate 2 have a plurality of grooves 10, and the torsion spring 3 is set on the hinge shaft , the end of the cover plate is provided with a block 4 engaged with the mounting plate, and a contact piece 5 is installed on the mounting plate. The upper end of the contact piece 5 is a contact end 6, and the lower end is a welding end 7. Both sides of the middle part have Press-fit part 8 , press-fit part 8 has inverted teeth 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com