Drill

A drill bit and plastic technology, applied in the direction of twist drills, drill accessories, drilling/drilling equipment, etc., can solve the problems of high expenditure costs, achieve long service life, reliable cutting, and avoid uneven effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

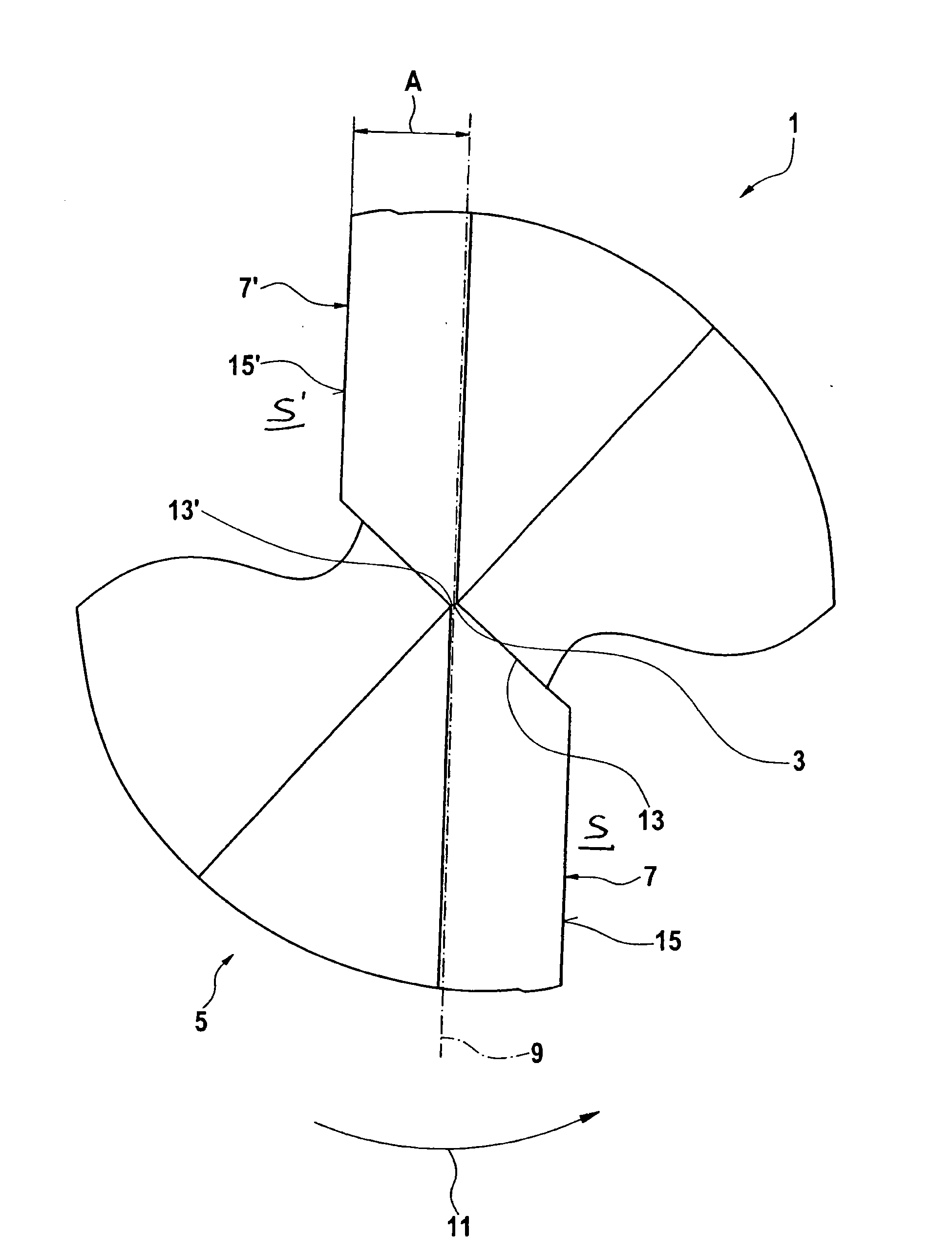

[0031] exist figure 1 A schematic top view of a first embodiment of the drill bit 1 is illustrated in . The viewing direction is from above towards the tip 3 of the drill 1 .

[0032] The drill 1 has a base body 5 on which a first main cutting edge 7 and a second main cutting edge 7' arranged centrally symmetrically with respect to the axis of rotation of the drill extending through the tip 3 are arranged. The two main cutting edges 7, 7' are arranged parallel to an imaginary straight line 9 extending through the axis of rotation and corresponding to the diameter line. The distance A between the straight line 9 and the main cutting edges 7, 7' is approximately 15% of the main hole diameter of the drill 1, respectively. The main borehole diameter is the diameter of the drill 1 measured radially between the points of the main cutting edges 7, 7' furthest from the axis of rotation, which lie in front of the straight line 9 in the direction of rotation of the drill 1 indicated b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com