Producing method of cyclohexanone product by Phenol hydrogenation reaction

A hydrogenation reaction, cyclohexanone technology, applied in chemical instruments and methods, preparation of organic compounds, preparation of carbon-based compounds, etc., can solve problems such as poor selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The features and functions of the present invention are further described below through specific examples, but they are not intended to limit the scope of the present invention.

[0011] According to the aforementioned preferred embodiments of the present invention, the hydrogenation reaction is carried out under the respective reaction conditions of each example to convert phenol into cyclohexanone.

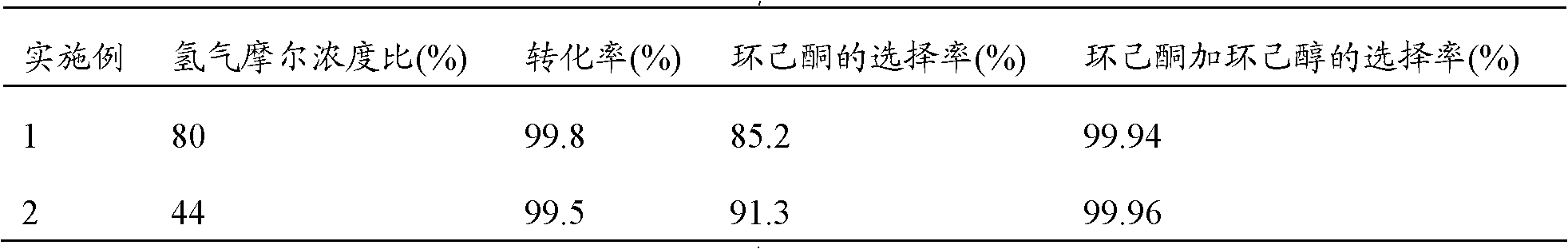

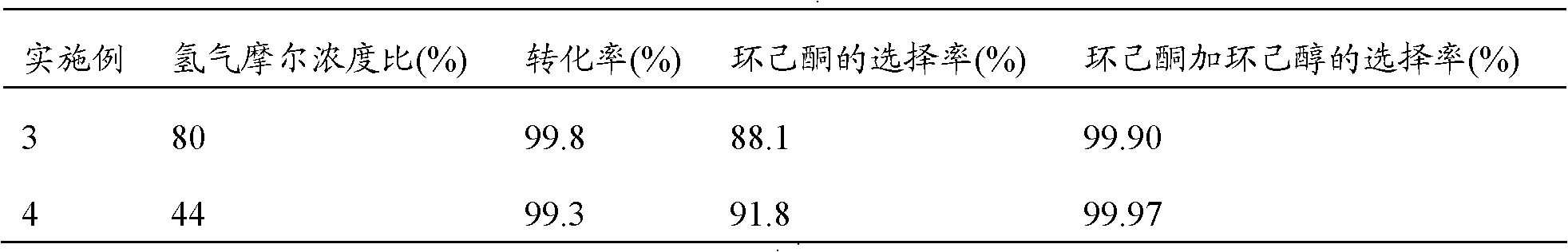

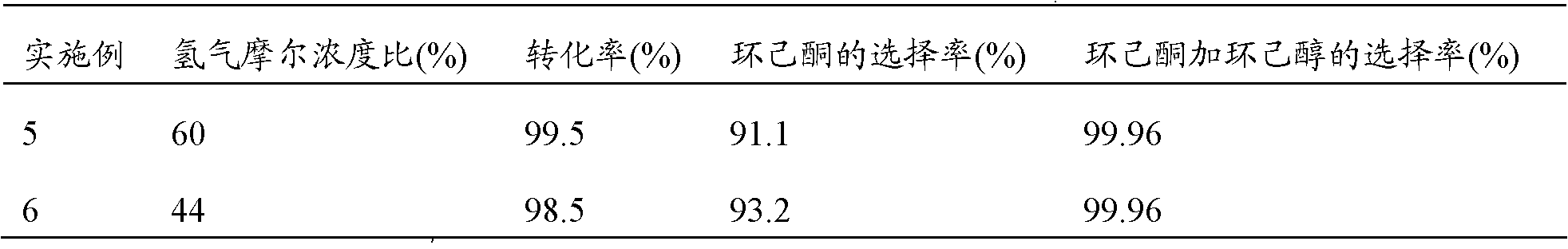

[0012] 1. The influence of hydrogen concentration on the reaction result:

[0013]

[0014] Reaction conditions: the gravimetric space velocity per hour is 1.5, the molar ratio of hydrogen to phenol is 4, and the reaction pressure is 14.7 psig.

[0015] The reaction of embodiment 1 and 2 uses Johnson Matthey commercial catalyzer (Type 355, contains 0.8%Pd), when adding hydrogen concentration ratio and down to 44% by 80%, the selectivity of reaction product cyclohexanone is promoted to 91.3% by 85.2% %, and the conversion rate of the whole reaction and the total amount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com