Circulating method for cold regenerated catalyst and catalytic cracking reaction regenerating system

A technology of catalyst circulation and reaction regeneration, applied in the petrochemical field, can solve problems such as inability to strip two kinds of solid particles, short heat transfer time, mixing of hot and cold catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

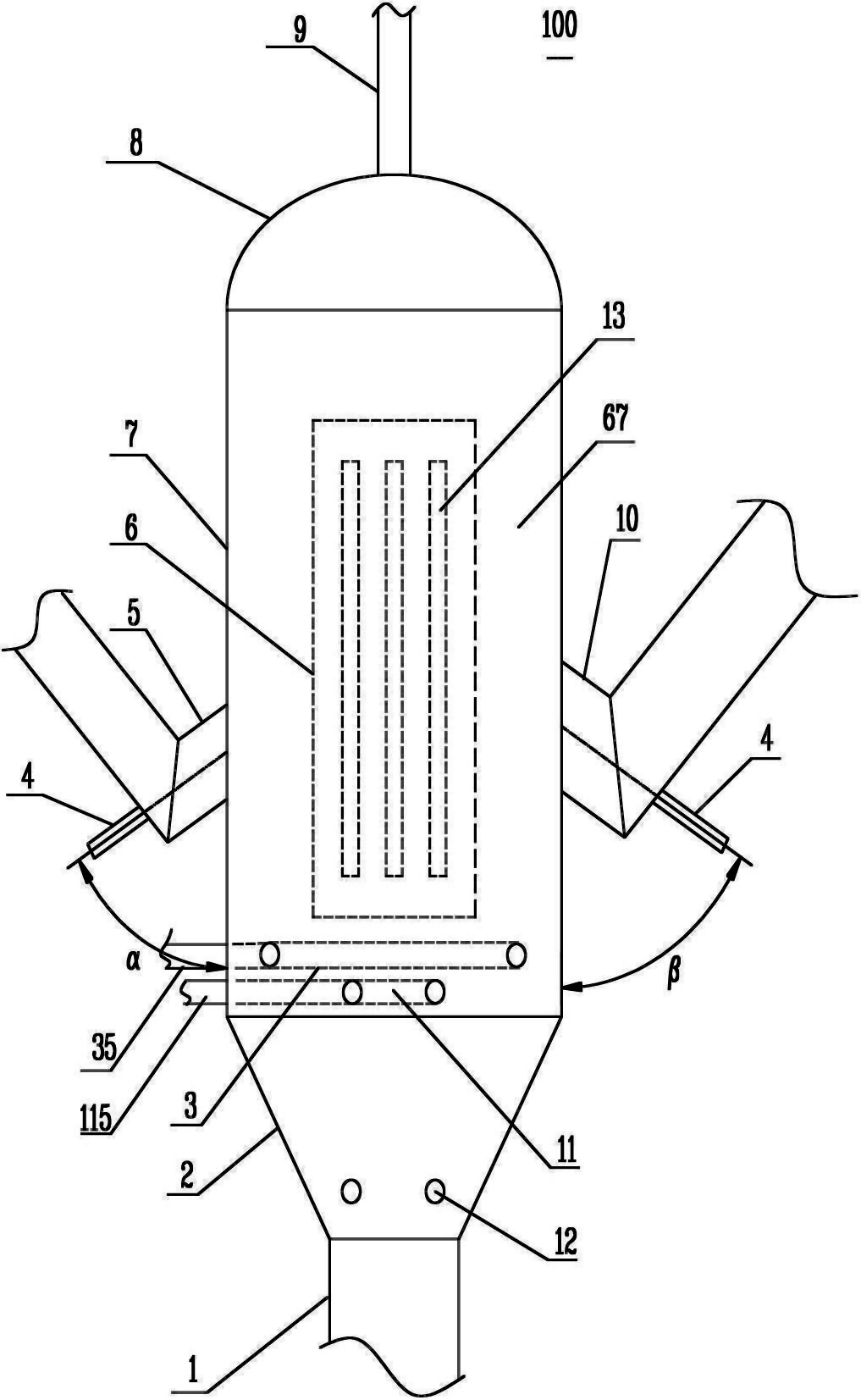

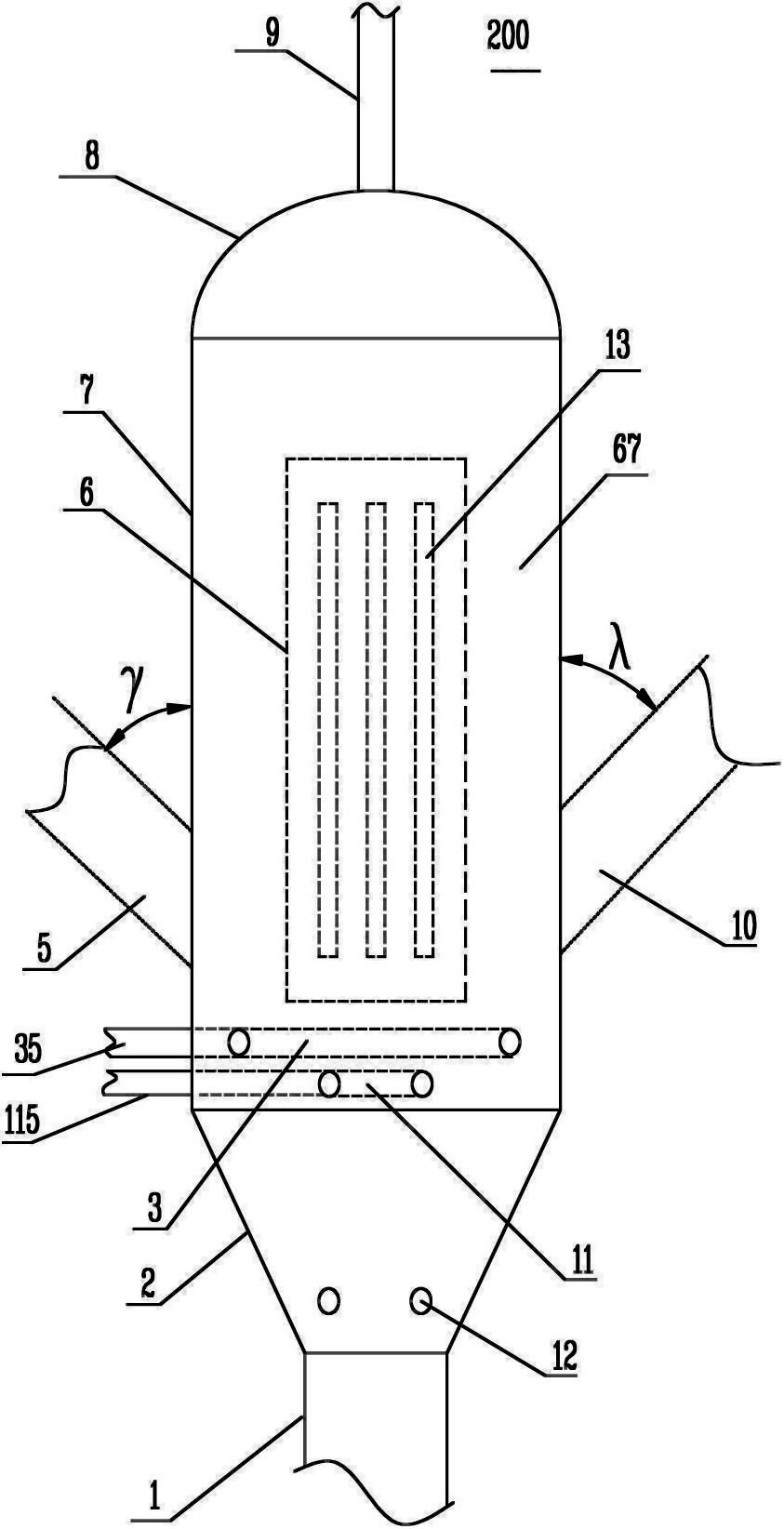

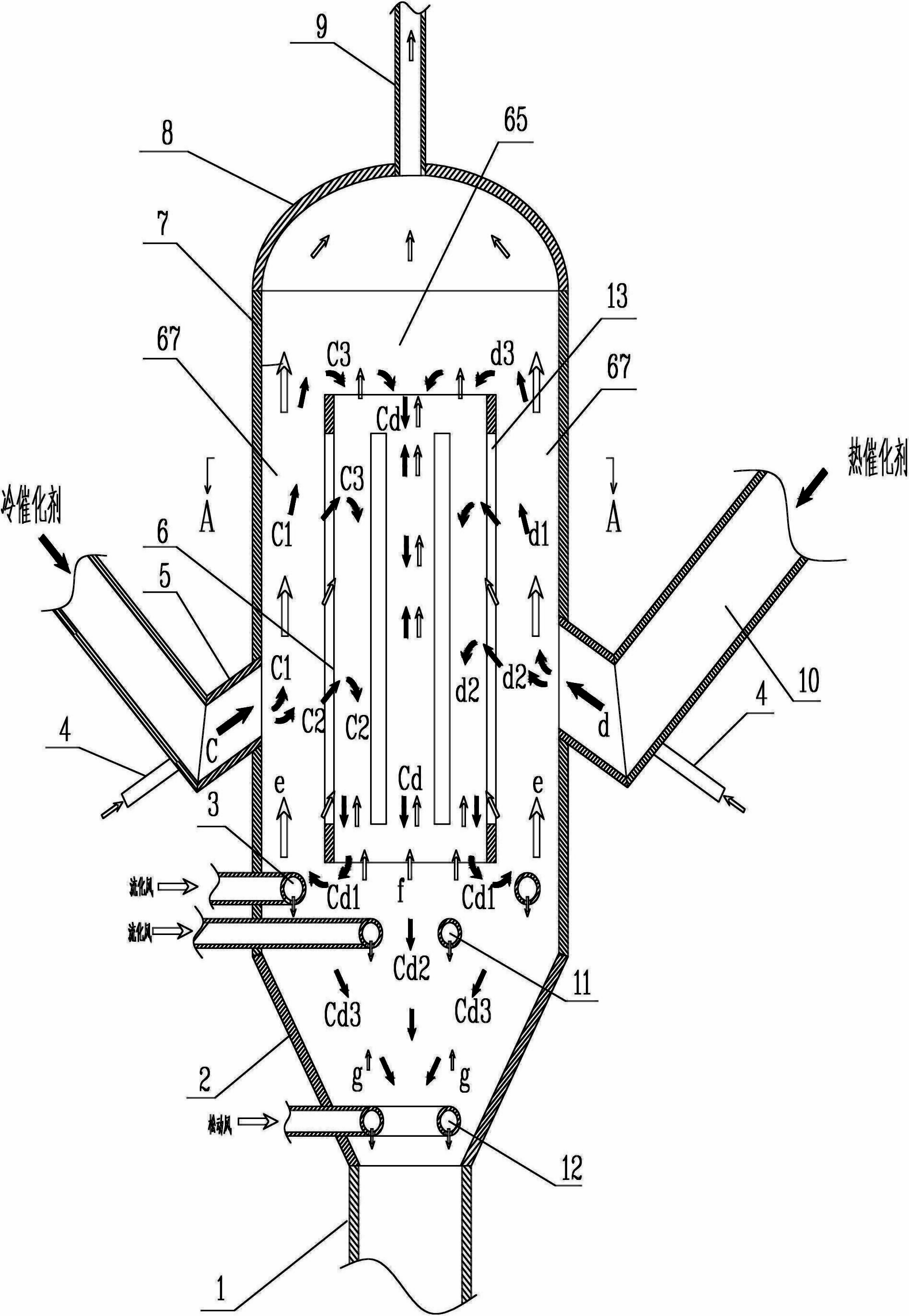

[0062] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

[0063] like Figure 10 to Figure 14 As shown, the present invention provides five catalytic cracking reaction regeneration systems, and these catalytic cracking reaction regeneration systems all include: a riser reactor 40, a pre-lift section 30, a regenerator 60, and a heat collector arranged outside the regenerator 60 70. These catalytic cracking reaction regeneration systems also include: a gas-solid circulation mixed stripper arranged outside the riser reactor and the pre-lift section, and the gas-solid circulation mixed stripper can be used in the regeneration form of the fluidized catalytic cracking process Mix the first solid particles and the second solid particles at different temperatures, and strip off the flue gas and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com