Color film substrate and manufacturing method thereof and touch control LCD (Liquid Crystal Display) panel

The technology of a color film substrate and manufacturing method, which is applied in the field of liquid crystal display, can solve the problems of increased power consumption, performance degradation, touch-type liquid crystal panel screen light transmittance and poor performance of lightness of use, and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

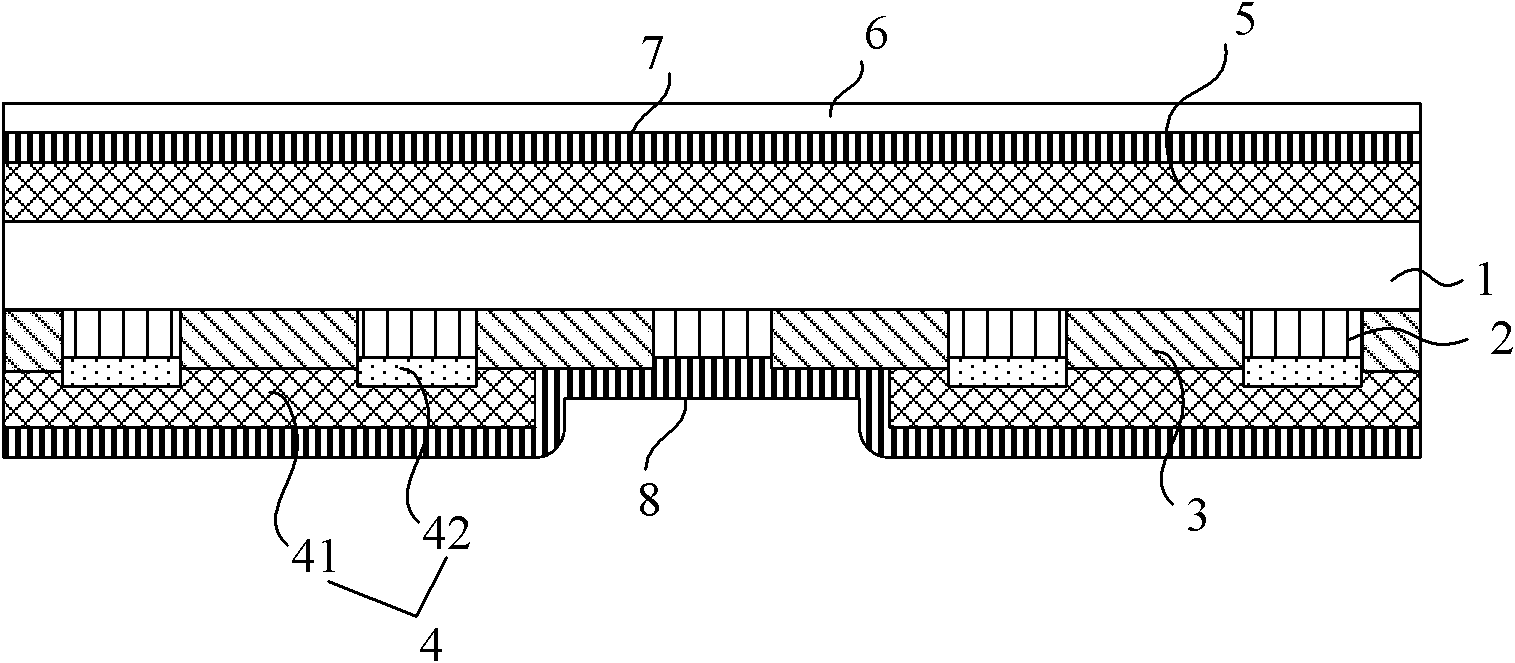

[0037] Such as figure 2 As shown, the color filter substrate provided in this embodiment includes:

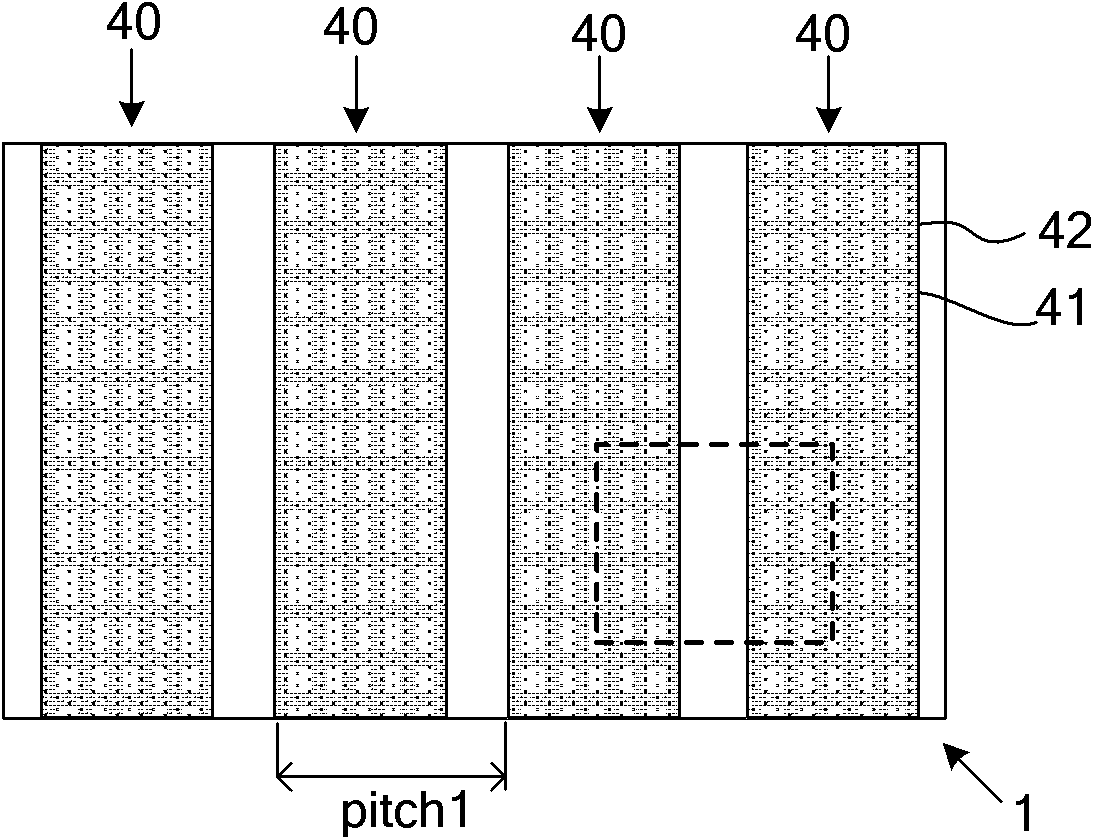

[0038] A substrate 1, a black matrix 2 and a color pixel unit 3 are arranged on the lower surface of the substrate 1, a driving electrode 4 is arranged on the black matrix 2 and the color pixel unit 3, a passivation layer 8 is arranged on the driving electrode 4, the passivation layer 8 A common electrode (not shown in the figure) is also arranged on the top;

[0039] A polarizer 6 is arranged on the upper surface of the substrate 1, a sensing electrode 5 is arranged between the substrate 1 and the polarizer 6, and a passivation layer 7 is also arranged between the sensing electrode 5 and the polarizer 6; in this embodiment, the The sensing electrodes 5 are arranged under the polarizer 6, so that the polarizer 6 can mechanically protect the sensing electrodes 5, effectively preventing the sensing electrodes from being damaged due to frequent touches by the user, but the prese...

Embodiment 2

[0052] Such as Figure 7 As shown, the difference between this embodiment and the first embodiment lies in that the driving electrodes 4 are disposed on the substrate 1 , and the black matrix 2 and the color pixel units 3 are disposed on the driving electrodes 4 . In this case, the surface of the substrate 1 on which the driving electrodes 4 are formed is flat, which can prevent the driving electrodes 4 from forming gaps. Therefore, in this embodiment, the driving electrodes 4 do not include metal electrode parts. Certainly, in this embodiment, the driving electrodes may still include the transparent electrode part 41 and the metal electrode part 42 as in the first embodiment, which is not limited in the present invention. Other structures of the color filter substrate in this embodiment are the same as those of the color filter substrate in Embodiment 1, and will not be repeated here.

Embodiment 3

[0054] Such as Figure 8 As shown, the difference between this embodiment and Embodiment 1 is that a polarizer 6 is arranged on the upper surface of the substrate 1, the sensing electrode 5 is arranged on the polarizer 6, and the surface of the sensing electrode 5 is provided with a passivation layer. 10. Other structures are the same as those of the color filter substrate in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com