Color paste switching device of micro-scale polyurethane elastomer pouring machine

A polyurethane elastomer and switching device technology, applied in household components, household appliances, other household appliances, etc., can solve problems such as difficult and beautiful pursuit, and achieve the effect of ensuring accuracy, precision, and good wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

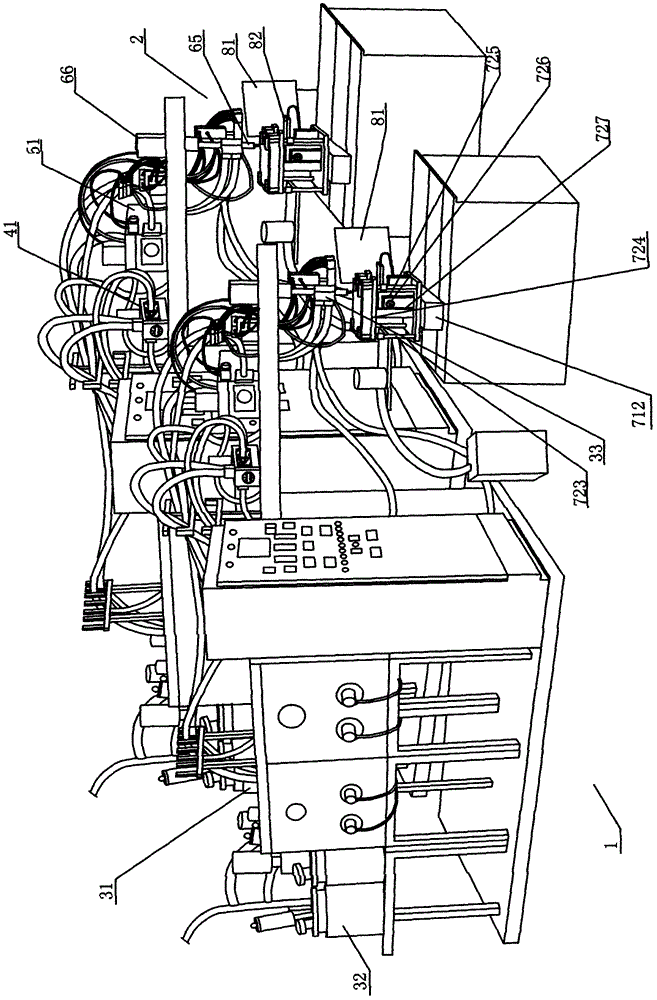

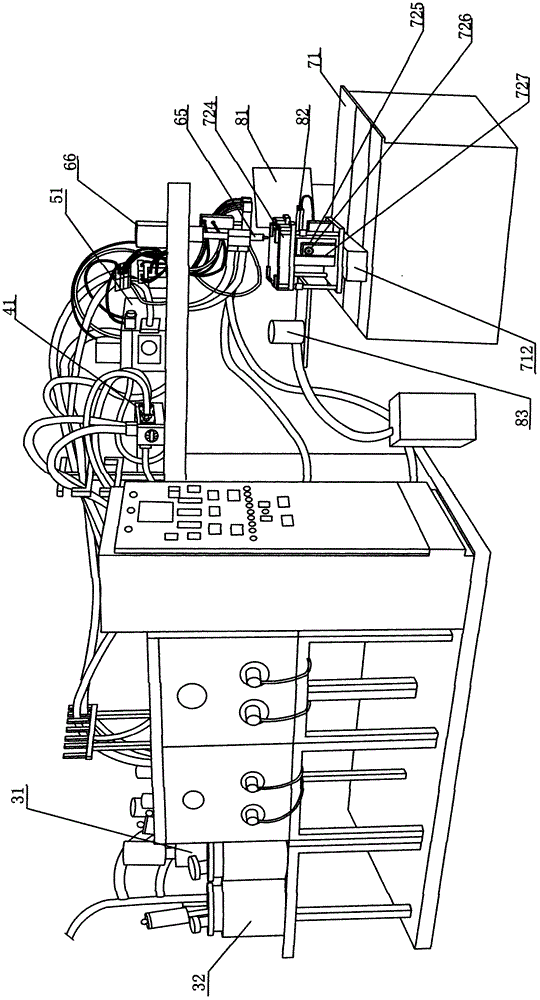

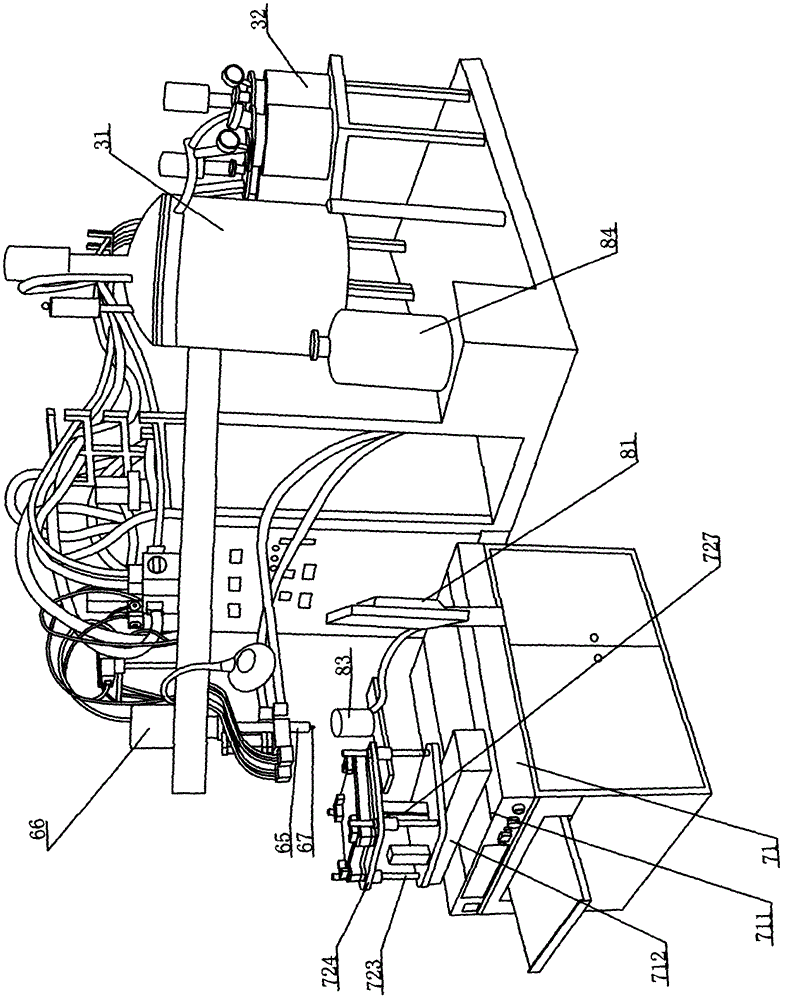

[0035] Such as figure 1 As shown, the present invention is a color paste switching device of a trace polyurethane elastomer filling machine, and its structure includes an upper filling machine 1 for filling the upper layer of the heel top 90 and a lower filling machine 2 for filling the lower layer of the heel top 90 , the upper filling machine 1 and the lower filling machine 2 both include a frame, a pressure cycle feeding mechanism arranged on the frame, a color paste switching device, a mixing and pouring device, a cleaning mechanism, a PLC programmable control system and a three-dimensional numerical control workbench, the pressure The cyclic feeding mechanism conveys the slurry and color material required for the upper and lower layers, and is controlled by the PLC programmable control system, and is delivered quantitatively according to the set pressure, and then switches the color material required by the color paste switching device, through mixing and pouring The devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com