Pneumatic hot-press device

A technology of hot pressing device and hot pressing plate, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., and can solve problems such as harmfulness to the human body, easy fatigue, and difficulty in ensuring hot pressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in conjunction with the preferred implementation examples of the accompanying drawings.

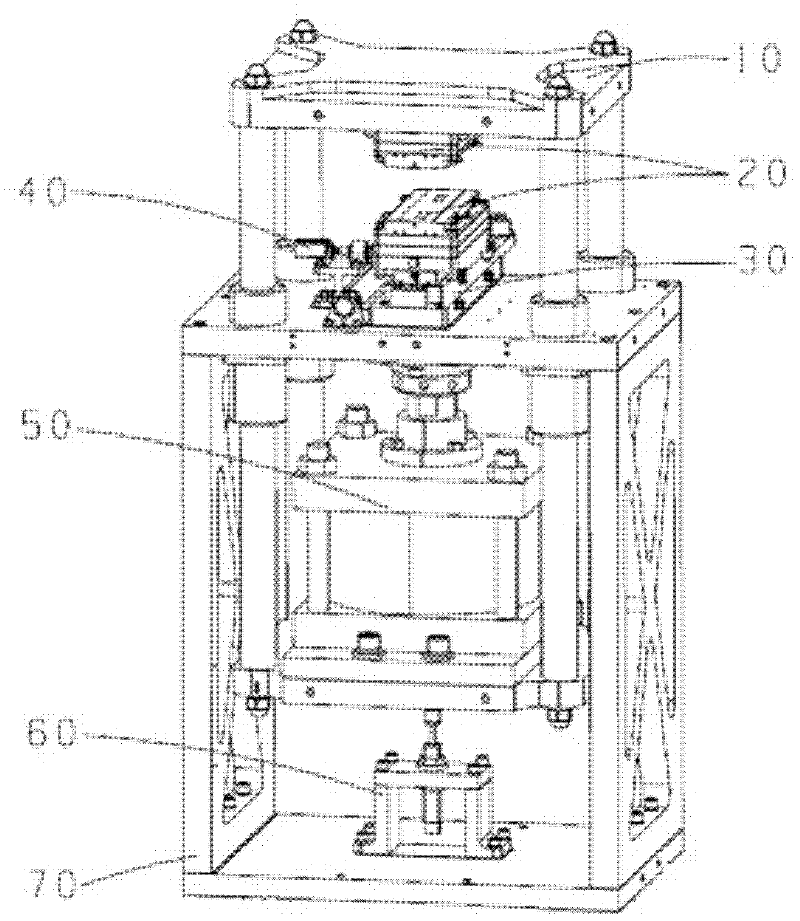

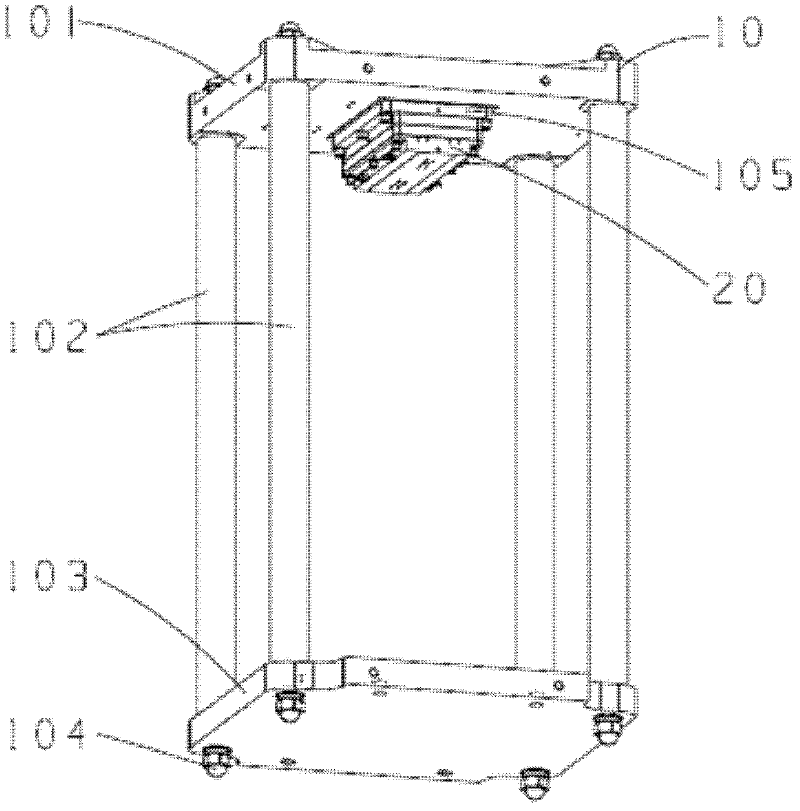

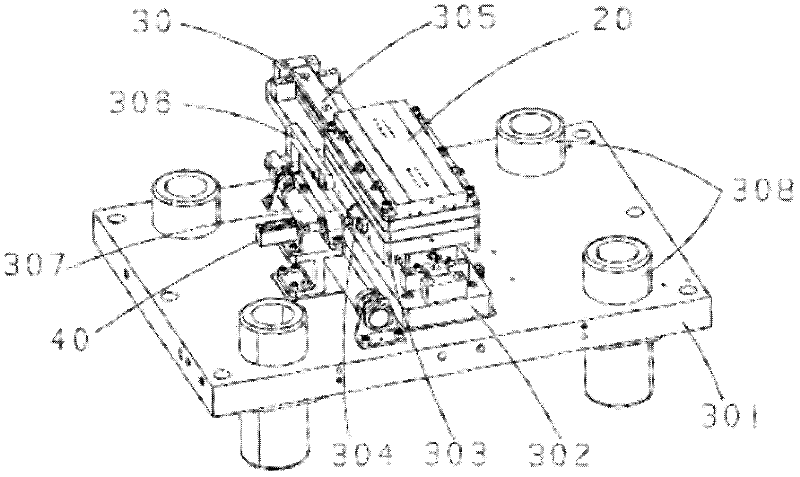

[0019] see figure 1 , The preferred embodiment of the present invention includes a guide assembly 10 , an upper heat press plate 101 , a lower heat press plate 301 , a heat press head 20 , a sliding assembly 30 , a tightening assembly 40 , a piston cylinder 50 , a buffer assembly 60 and a bracket 70 . A lower hot pressing plate 301 is fixed on the support, and an upper hot pressing plate 101 and a piston-cylinder adapter plate 103 are respectively arranged above and below the lower hot pressing plate 301. The upper hot pressing plate 101, the lower hot pressing plate 301 and the piston-cylinder adapter The connecting plates 103 are sequentially connected by the guide posts 102 to form an integral moving assembly. The thermal pressure head 20 described therein comprises two electrically heated thermal pressure heads of the same struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com