Mechanical moving type alfalfa root cap microspray irrigation device

A mobile, alfalfa root technology, applied in watering devices, climate change adaptation, gardening, etc., can solve the problems of discounted water saving effect, large proportion of water loss, and decreased irrigation water utilization efficiency, so as to avoid evaporation loss , the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0019] Mechanical mobile type alfalfa root cap micro-sprinkler irrigation device of the present invention, its preferred embodiment is:

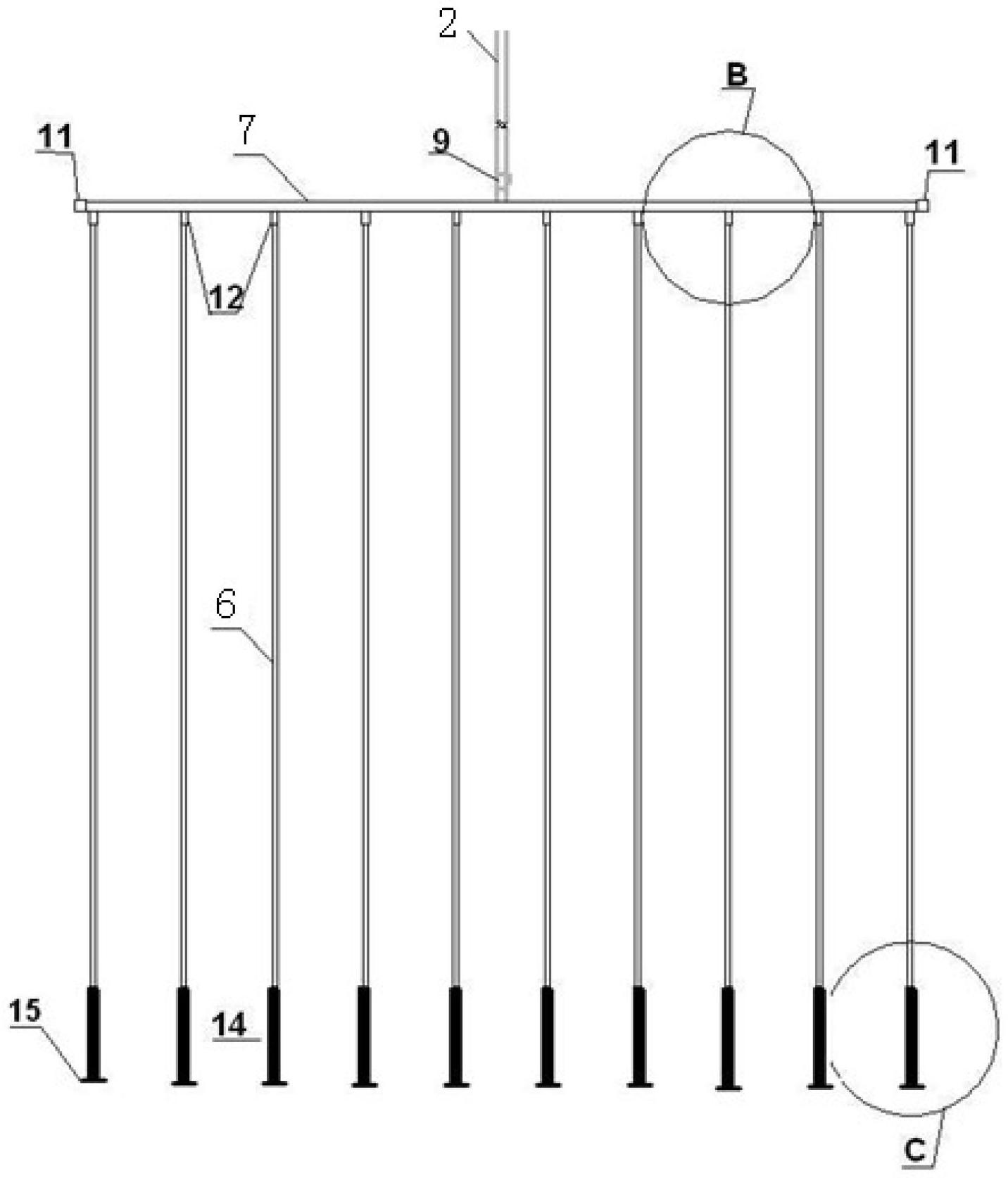

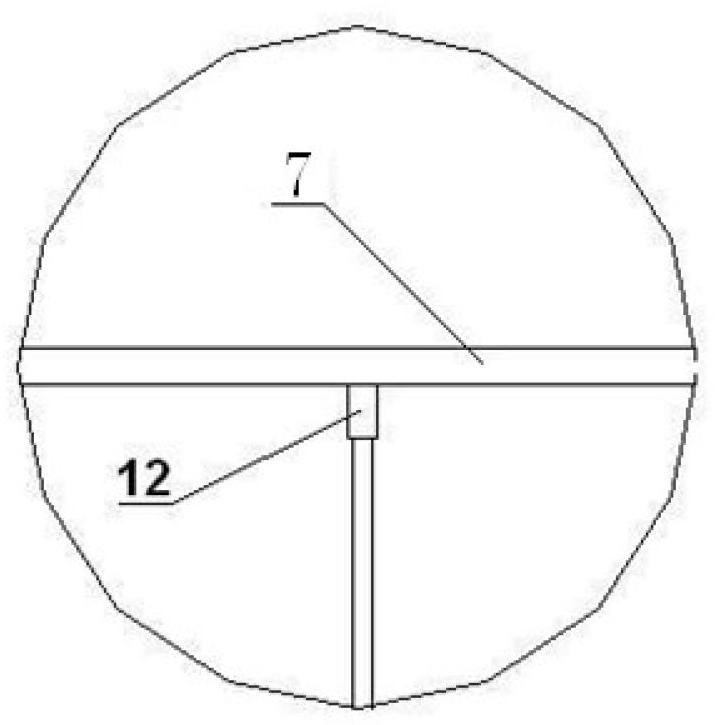

[0020] It includes a plurality of branch pipes leading down from the main water supply pipe of the sprinkler irrigation machine, a water inlet valve is provided at the end of each branch pipe, and the water inlet valve is connected to a water distribution pipe, and a plurality of vertical pipes are arranged on the water distribution pipe. The end of the vertical pipe is provided with a balance pipe, and the lower end of the balance pipe is provided with a micro spray head.

[0021] The pipe diameter of the water distribution pipe is the same as that of the branch pipe, the branch pipe and the water distribution pipe are connected by a straight tee, and plugs are provided at both ends of the water distribution pipe.

[0022] The material of the water distribution pipe is hard polyvinyl chloride pipe, stainless steel pipe or galvanized steel p...

specific Embodiment

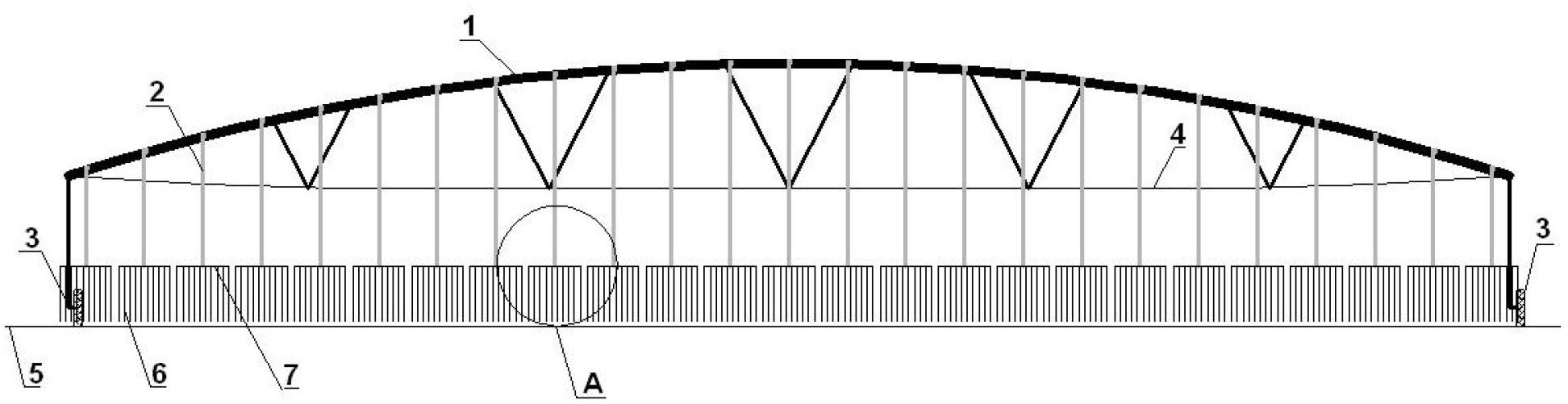

[0041] Such as figure 1 As shown, the root cap micro-sprinkler irrigation device diverts water from the main water supply pipe 1 of the sprinkler irrigation machine, and is transported to the water distribution pipe 7 and the vertical pipe 6 of the root cap micro-sprinkler irrigation device of the present invention through the branch pipe 2 . Every span of the sprinkler is realized by driving wheel 3 to rotate or walk on the ground 5, and the original structure 4 of the sprinkler remains unchanged.

[0042]The root cap micro-sprinkler irrigation device of the present invention is represented by a set, and multiple sets of root cap micro-sprinkler irrigation devices can be configured on each span of the sprinkler truss according to the original nozzle spacing, except for the tail spray guns of some central pivot type sprinkler irrigation machines. The root and crown micro-sprinkler irrigation device configured is equal to the number of original nozzles. For example, a 7-span c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com