Method for preparing solid florfenicol dispersion

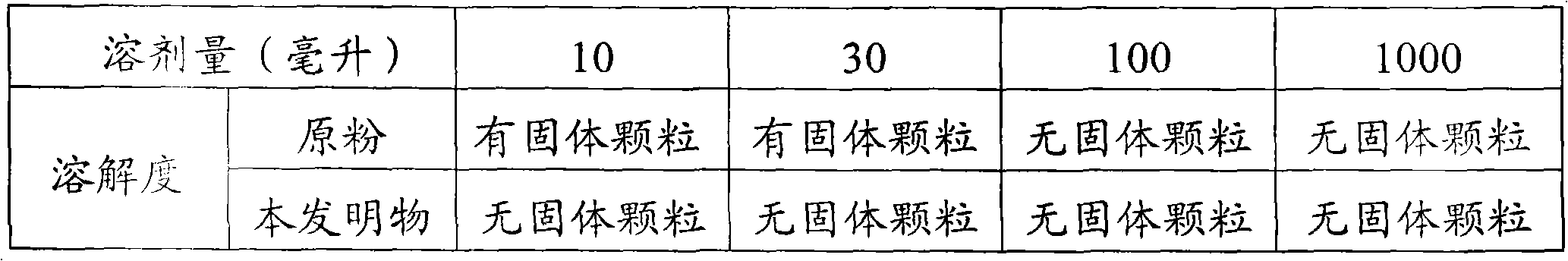

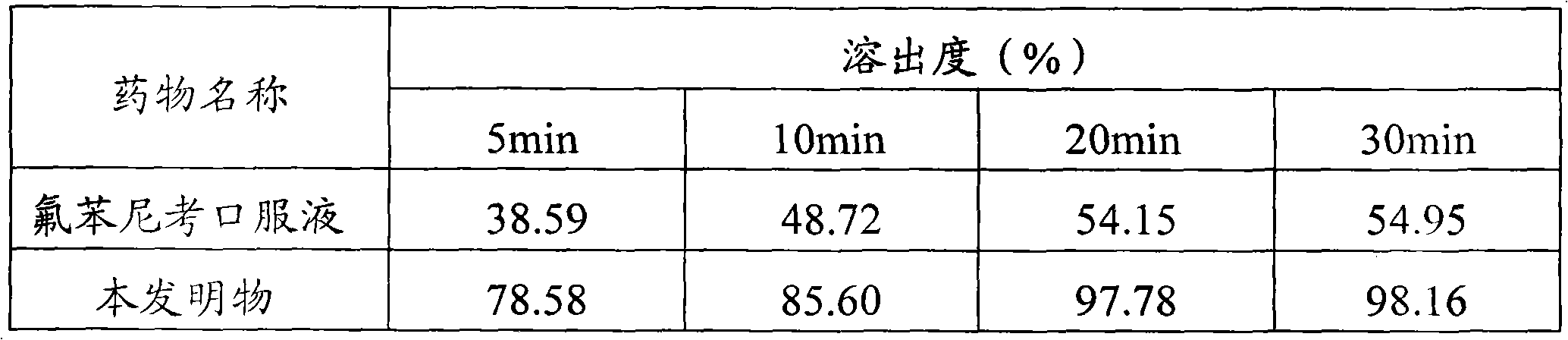

A technology of solid dispersion and florfenicol, which is applied in the direction of non-active ingredient medical preparations, medical preparations containing active ingredients, pharmaceutical formulas, etc., can solve the problem of poor water solubility of florfenicol, troublesome clinical application, and influence Problems such as popularization and use, to achieve the effect of simple preparation process and improved solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A kind of preparation method of florfenicol solid dispersion, carry out as follows: (every part is calculated by 10g)

[0019] (1) Take by weight 150 parts of Florfenicol (over 80 mesh sieves), 150 parts of poloxamers, and 500 parts of polyethylene glycol-4000;

[0020] (2) Heat and melt the poloxamer and polyethylene glycol-4000, stir for 3 to 5 minutes until uniform, add Florfenicol, and stir evenly;

[0021] (3) Rapidly cool the mixture obtained in (2) to -10°C, and pulverize to obtain the florfenicol solid dispersion.

Embodiment 2

[0023] A kind of preparation method of florfenicol solid dispersion, carry out as follows: (every part is calculated by 10g)

[0024] (1) Take by weight 200 parts of Florfenicol (over 80 mesh sieves), 200 parts of poloxamers, and 600 parts of polyethylene glycol-4000;

[0025] (2) Heat and melt the poloxamer and polyethylene glycol-4000, stir for 3 to 5 minutes until uniform, add Florfenicol, and stir evenly;

[0026] (3) Rapidly cool the mixture obtained in (2) to -10°C, and pulverize to obtain the florfenicol solid dispersion.

Embodiment 3

[0028] A kind of preparation method of florfenicol solid dispersion, carry out as follows: (every part is calculated by 10g)

[0029] (1) Take by weight 250 parts of Florfenicol (over 80 mesh sieves), 250 parts of poloxamers, and 700 parts of polyethylene glycol-4000;

[0030] (2) Heat and melt the poloxamer and polyethylene glycol-4000, stir for 3 to 5 minutes until uniform, add Florfenicol, and stir evenly;

[0031] (3) Rapidly cool the mixture obtained in (2) to -10°C, and pulverize to obtain the florfenicol solid dispersion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com