Unfolding and machining method for single-bent thin-walled parts

A technology of thin-walled parts and thin-walled parts, applied in the field of sheet metal forming, can solve the problems that the position and size of the milling grid are not very accurate, not suitable for product design requirements, and the wall thickness tolerance of parts cannot be guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

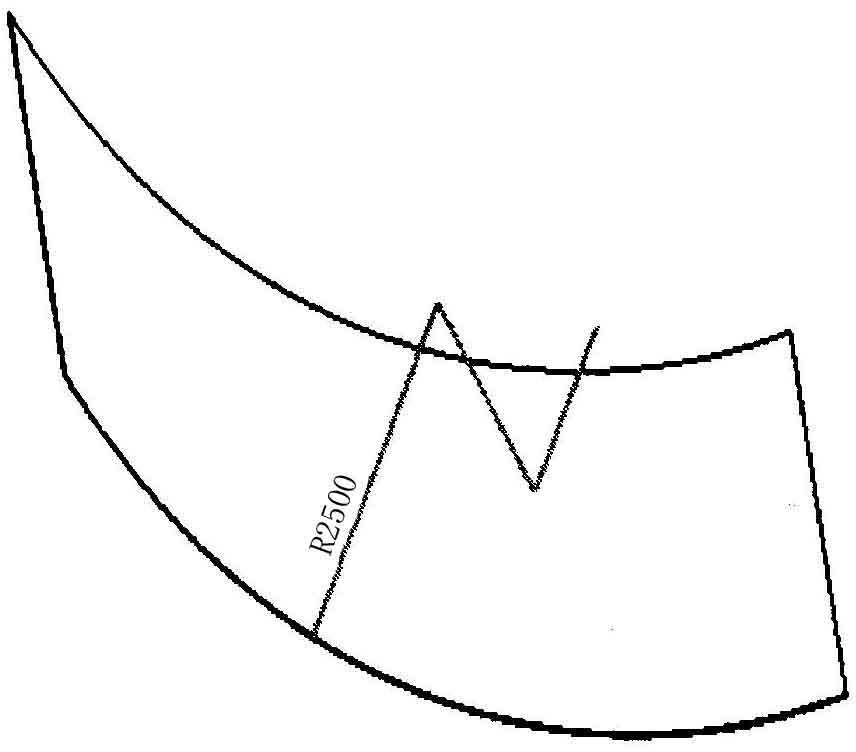

[0013] Such as figure 1 As shown, for an aluminum-lithium alloy 2198 thin plate with an outer dimension of 3200mm×2100mm×3.175mm, after the size of the part needs to be processed, the radius of curvature is required to be 1667.5mm. The unfolding machining method for this single-curved thin-walled part includes the following steps:

[0014] 1) Pre-rolling of thin-walled parts: the radius of rolling thin-walled parts is 1000mm larger than the final curvature radius of 1667.5mm, and the pre-rolling radius is 2500mm~2600mm;

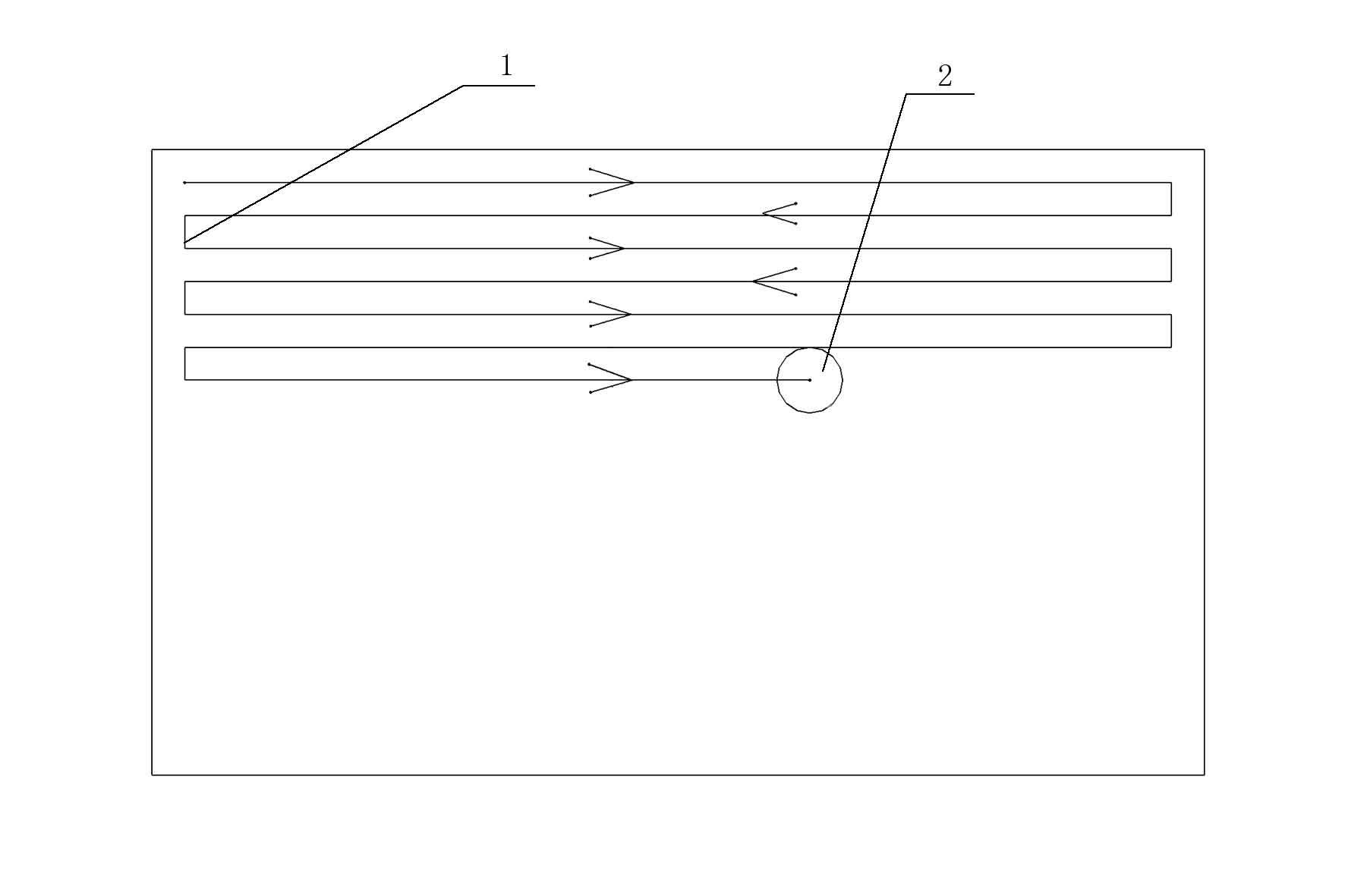

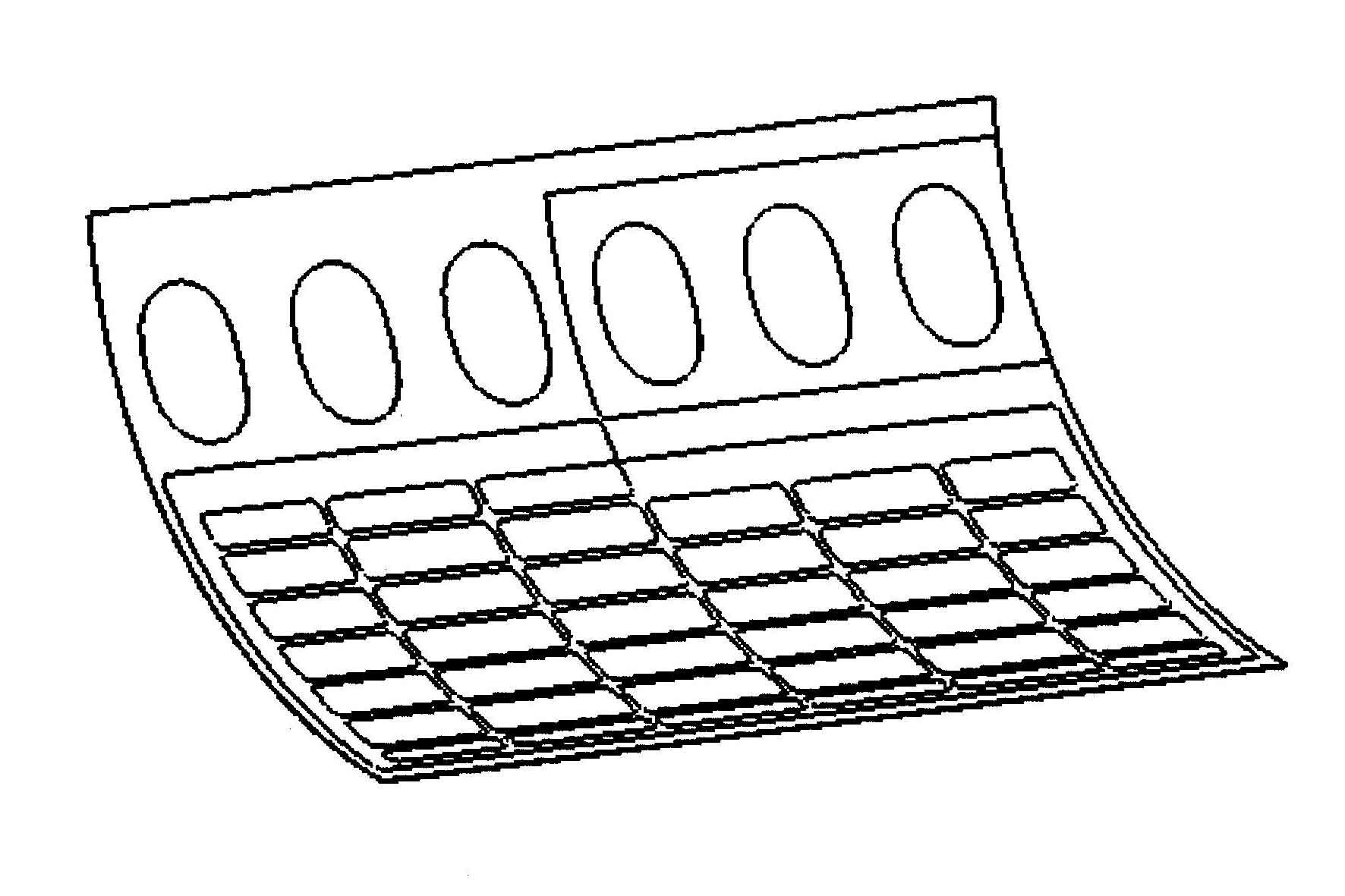

[0015] 2) A large number of tests have proved that when the pre-rolling radius of the thin-walled part is greater than R1000mm, when the thin-walled part is unfolded and clamped, the force on the thin-walled part has no effect on the final weight of the thin-walled part, so the thin-walled part Unfold machining; unfold the thin-walled parts on the vacuum platform of the CNC equipment and clamp them to keep the processing surface level of the thin-walled parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius of curvature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com