Salt spray test communication cable inner-layer coating material and production method thereof

A communication cable and salt spray test technology, applied in the direction of coaxial cable/analog cable, etc., can solve problems such as equipment failure and affect the quality of communication signals, achieve high waterproof performance, promote economic and social development, and increase production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

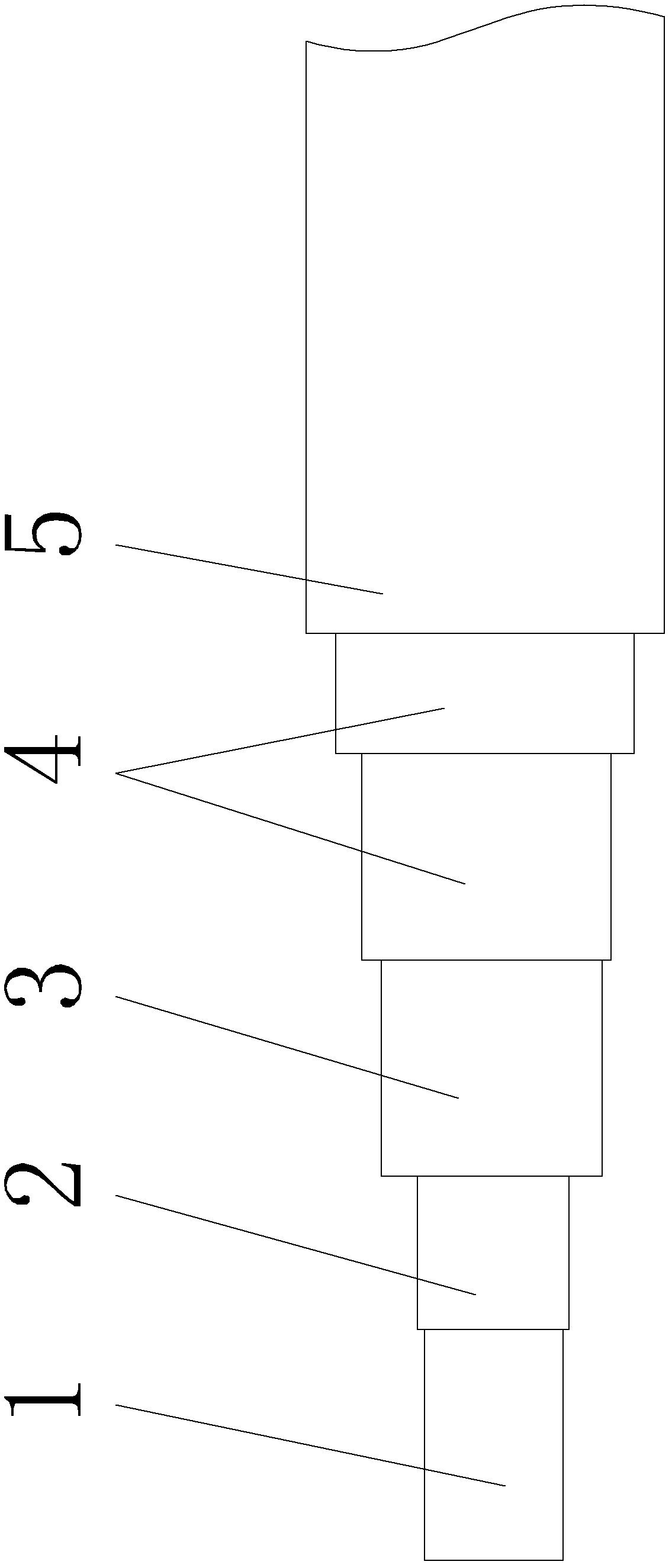

Image

Examples

Embodiment 1

[0034] A production process for the inner coating material of a communication cable for salt spray test, according to the following steps:

[0035] (1) Ingredients: weigh linear low density polyethylene, ethylene acrylic acid copolymer, copper corrosion inhibitor, calcium stearate, and copper antioxidant in a weight ratio of 82:11:1:1:1;

[0036] (2) Prepare masterbatch: use a mixer to mix linear low-density polyethylene and ethylene acrylic acid copolymer for 10 minutes; then plasticize and knead through the screw of the extruder, cut and granulate to prepare masterbatch;

[0037] (3) Prepare additives: mix copper corrosion inhibitor, calcium stearate, and copper antioxidant evenly to prepare additives, and then use a mixer to mix with the masterbatch; the mixing time is 3 minutes, and the mixer speed is 100 rev / min;

[0038] (4) Extrusion and cutting: Add the mixed material from the feeding port of the extruder, and cut it into granules after being plasticized and kneaded b...

Embodiment 2

[0040] A production process for the inner coating material of a communication cable for salt spray test, according to the following steps:

[0041] (1) Ingredients: weigh linear low density polyethylene, ethylene acrylic acid copolymer, copper corrosion inhibitor, calcium stearate, and copper antioxidant in a weight ratio of 86:15:1:1:1;

[0042] (2) Prepare masterbatch: use a mixer to mix linear low-density polyethylene and ethylene acrylic acid copolymer for 15 minutes; then plasticize and knead through the screw of the extruder, cut and granulate to prepare masterbatch;

[0043](3) Preparation of additives: the copper corrosion inhibitor, calcium stearate, and copper antioxidant are mixed evenly to prepare additives, and then mixed with the masterbatch by a mixer; the mixing time is 7 minutes, and the mixer speed is 200 rev / min;

[0044] (4) Extrusion and cutting: Add the mixed material from the feeding port of the extruder, and cut it into granules after being plasticized...

Embodiment 3

[0046] A production process for the inner coating material of a communication cable for salt spray test, according to the following steps:

[0047] (1) Ingredients: weigh linear low density polyethylene, ethylene acrylic acid copolymer, copper corrosion inhibitor, calcium stearate, and copper antioxidant in a weight ratio of 84:13:1:1:1;

[0048] (2) Prepare masterbatch: use a mixer to mix linear low-density polyethylene and ethylene acrylic acid copolymer for 12 minutes; then plasticize and knead through the screw of the extruder, cut and granulate to prepare masterbatch;

[0049] (3) Preparation of additives: the copper corrosion inhibitor, calcium stearate, and copper antioxidant are mixed evenly to prepare additives, and then mixed with the masterbatch by a mixer; the mixing time is 5 minutes, and the mixer speed is 150 rev / min;

[0050] (4) Extrusion and cutting: Add the mixed material from the feeding port of the extruder, and cut it into granules after being plasticize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com