Composite disperse dye composition

A dye composition, composite dispersion technology, applied in the direction of organic dyes, etc., can solve the problems of complex composition, serious composition, fiber contamination, etc., and achieve the effects of good levelness, improved sublimation fastness, and excellent fastness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10

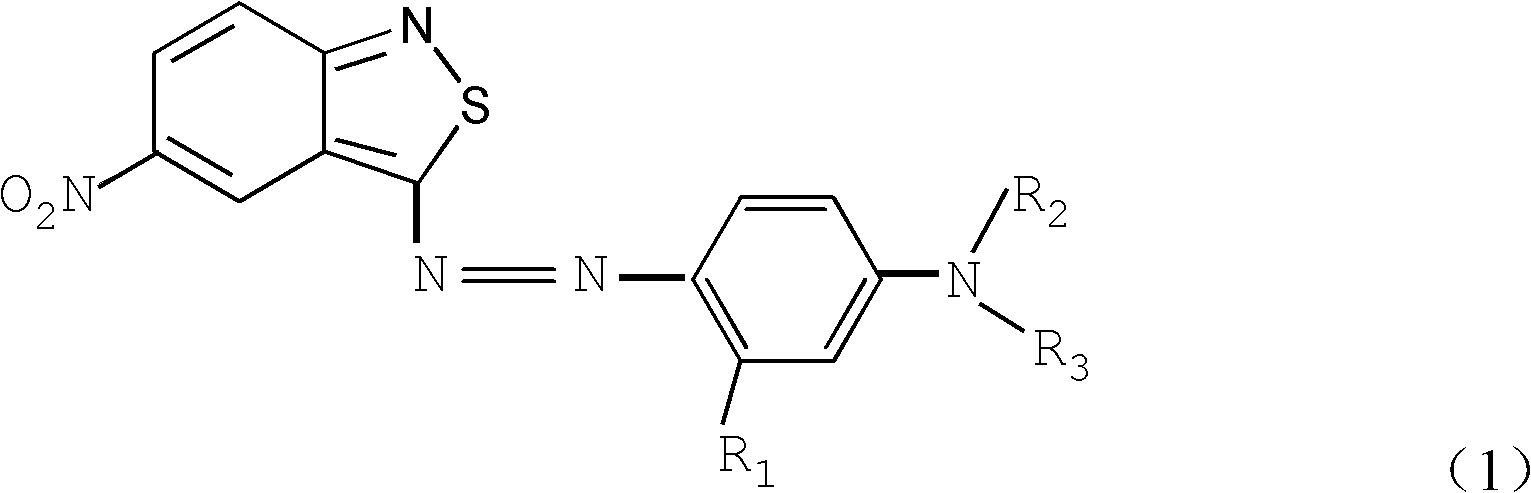

[0043] According to the data shown in Table 1, dye component A, component B and auxiliary agent (methylnaphthalenesulfonic acid formaldehyde condensate (dispersant MF), naphthalenesulfonic acid formaldehyde condensate (diffusion agent NNO) or lignosulfonic acid Sodium (lignin 83A, 85A)), mixed with water, ground and dispersed with a sand mill, and then spray-dried.

[0044] The dye components therein can be commercially available or self-prepared.

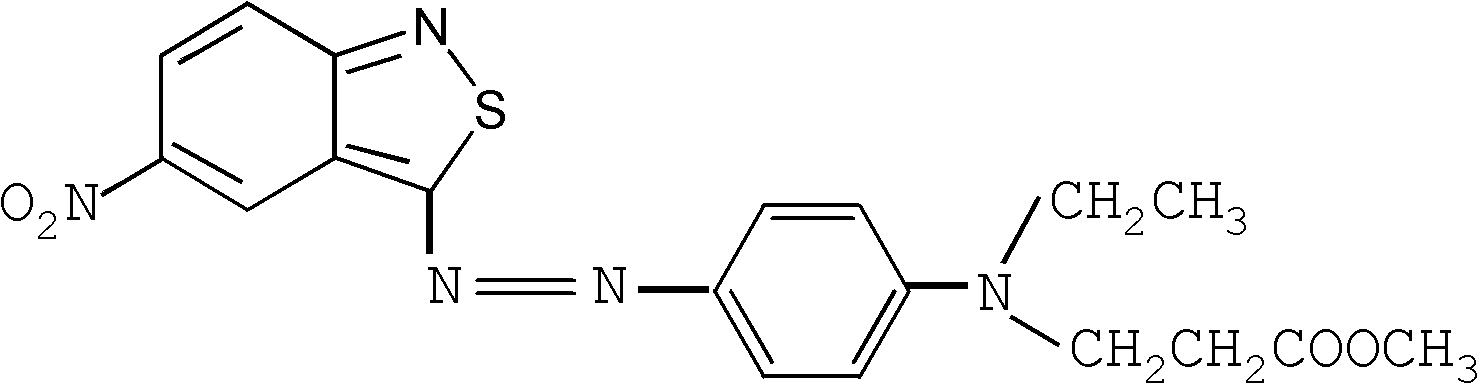

[0045] Structural formula (1-1) can adopt the disperse blue 148# that Zhejiang Runtu Co., Ltd. produces ("world dye species-2005" volume, the 594th page);

[0046] Structural formula (1-2) can adopt the disperse blue 367# that Zhejiang Runtu Co., Ltd. produces ("world dyestuff variety-2005" volume, the 606th page);

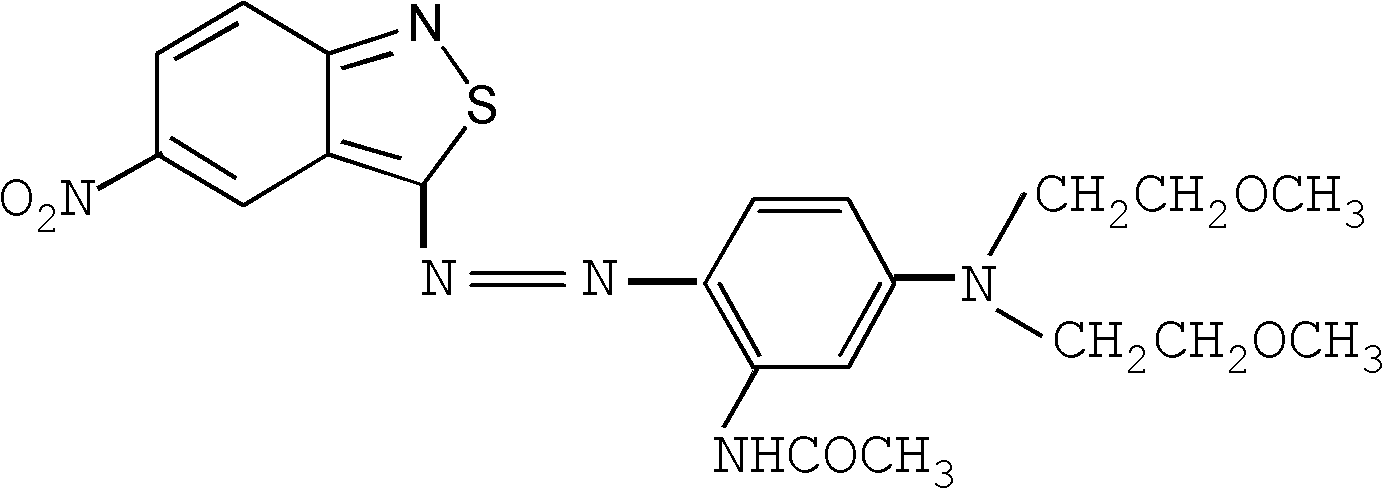

[0047] Structural formula (2-1) can adopt Disperse Orange 44# produced by Zhejiang Runtu Co., Ltd. ("World Dyestuff Varieties-2005" volume, page 527);

[0048] Structural formula (2-2) can adopt Disperse Orange 68# p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com