Guiding centralizer mechanism for single-pile foundation of offshore wind turbine

A single-pile foundation and offshore wind turbine technology, applied to foundation structure engineering, sheet pile walls, buildings, etc., can solve problems such as not so obvious, inclination, deflection of pile foundation, etc., to ensure normal operation and improve wind power generation efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

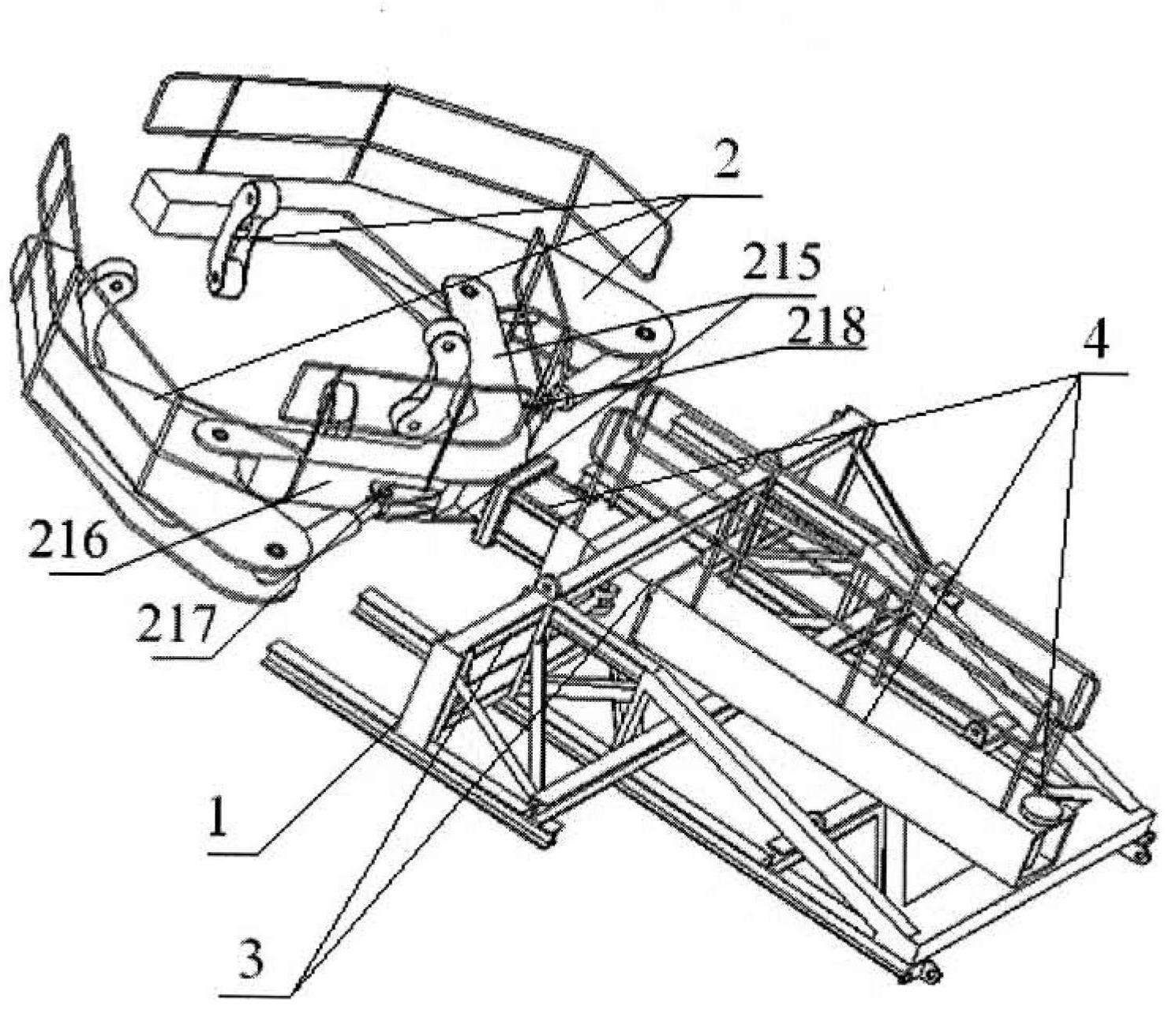

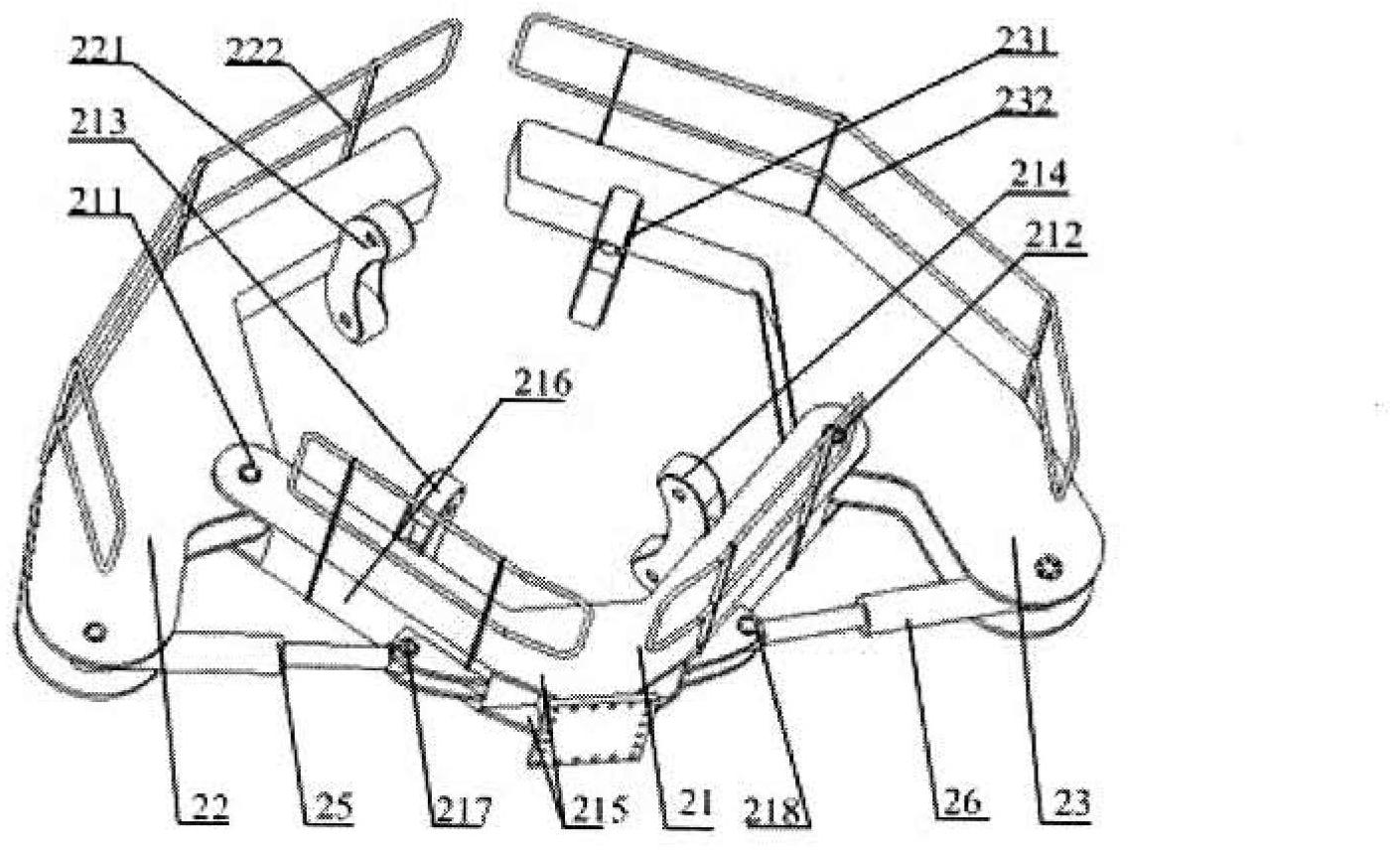

[0025] like figure 1 As shown, the guide and righting mechanism of the single pile foundation of the offshore wind turbine of the present invention is characterized in that it includes a frame 1, a clamping and guiding mechanism 2, a horizontal adjustment mechanism 3 and a vertical adjustment mechanism 4; the frame 1 is fixed on the working hull, The horizontal adjustment mechanism 3 and the vertical adjustment mechanism 4 are arranged on the frame 1 , and the clamping and guiding mechanism 2 is connected with the vertical adjustment mechanism 4 .

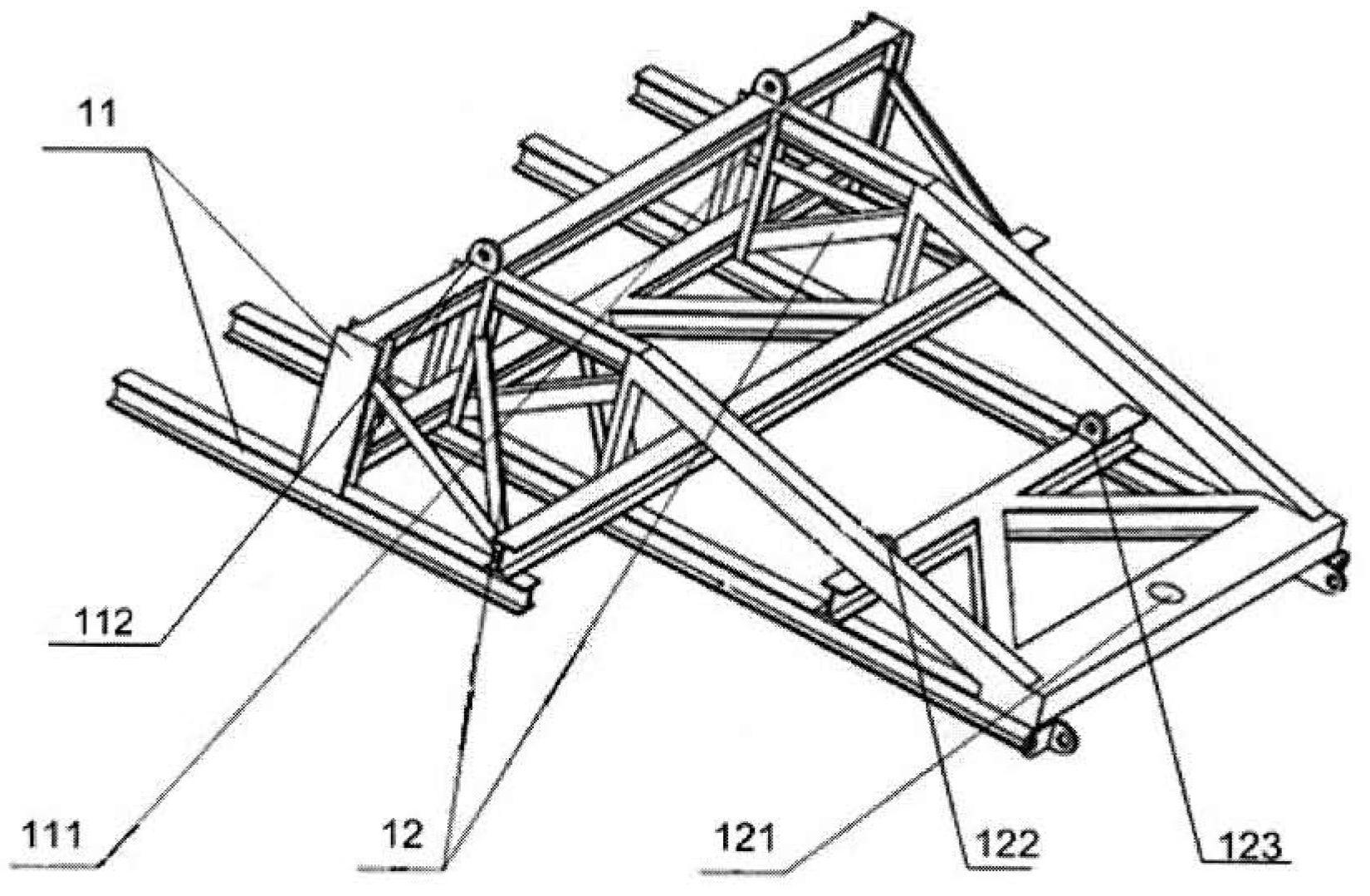

[0026] like figure 1 , figure 2As shown in the present invention, the guiding and straightening mechanism of the single-pile foundation of the offshore wind turbine, wherein the frame 1 is a truss structure composed of a bracket 11 with a T-shaped cross section and an underframe 12 with a ㄇ-shaped cross-section. 11 is arranged at one end of the underframe 12 with a ㄇ-shaped cross section close to the opening, and the closed end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com